09-15/2025

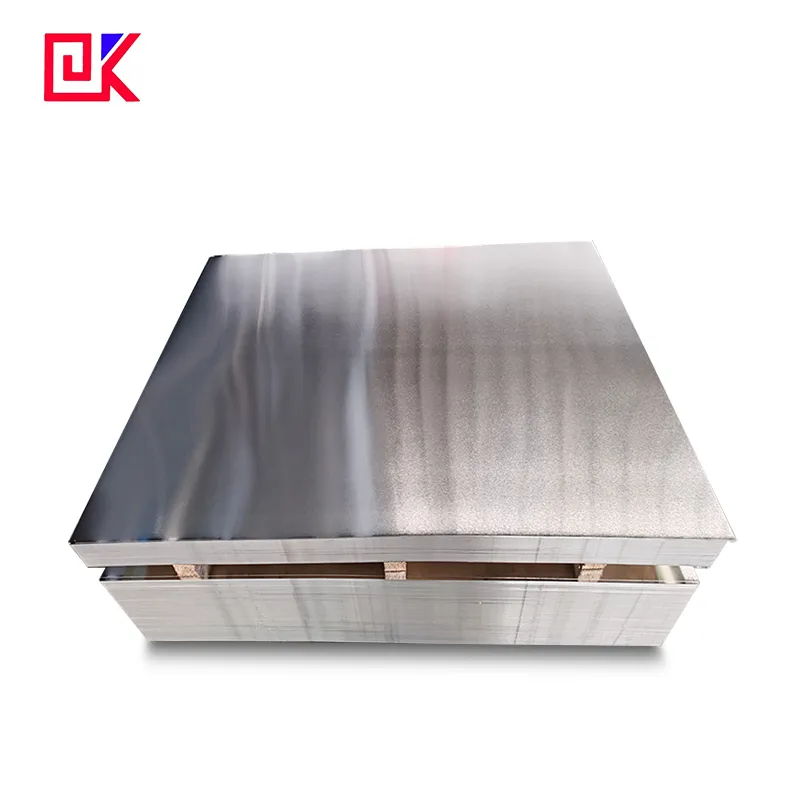

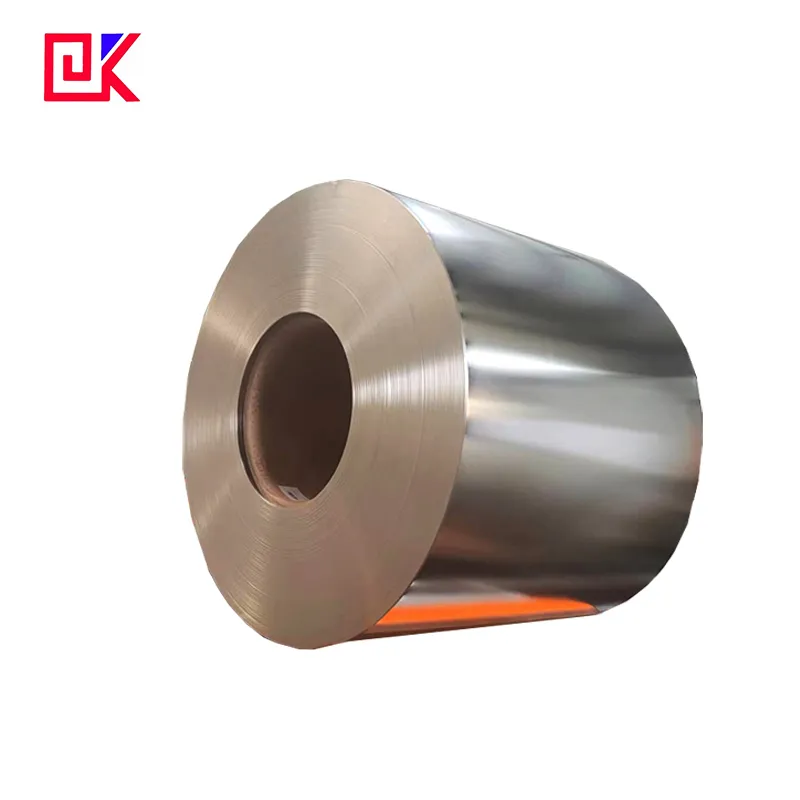

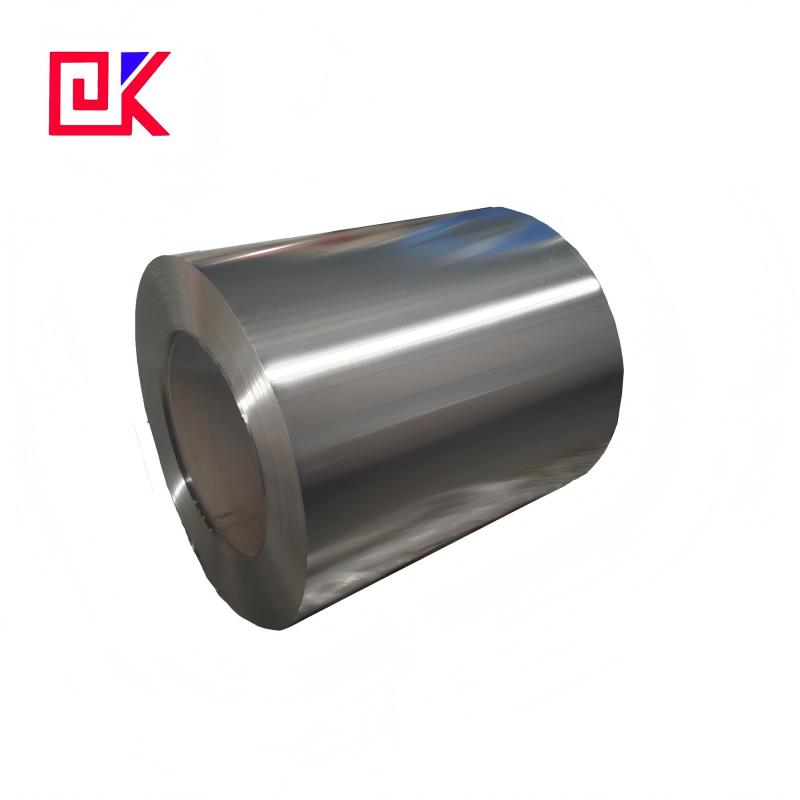

Tinplate applications of varying thicknesses:

1. Thin Tinplate (0.13mm to 0.20mm)

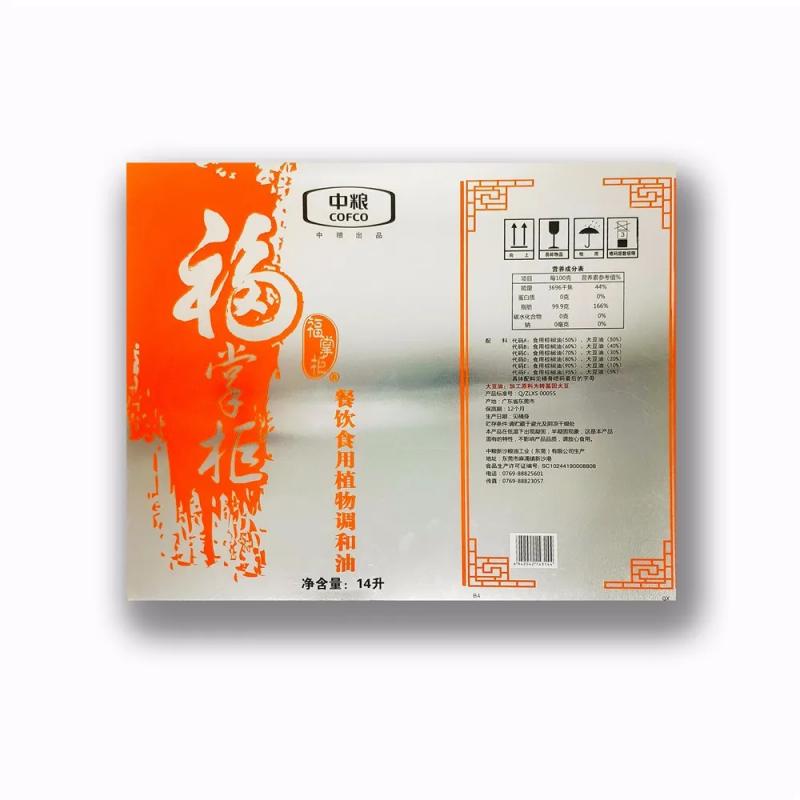

1.1 Food and beverage cans

1.2 Biscuit boxes and candy packaging

1.3 Cosmetics and perfume containers

2. Medium Tinplate (0.21mm to 0.30mm)

2.1 Food cans

2.2 Paint cans and chemical packaging

2.3 Can caps and closures

3. Thick Tinplate (0.31mm to 0.50mm)

3.1 Large paint cans and chemical containers

3.2 Construction and decorative materials

3.3 Industrial packaging containers