Metal materials are widely used in modern industry, especially in the field of packaging. Metal materials are favored by enterprises for their excellent physical properties and processing properties. However, misunderstandings about tinplate plate and aluminum are common among the public. Many people think that tinplate plate is aluminum or that the two have similar properties. In fact, although tinplate sheet and aluminum are both common metal materials, they have significant differences in composition, performance, application, etc.

This article will analyze the difference between tinplate plate and aluminum in detail and answer the core question of "Is tinplate plate aluminum?"

Is tinplate plate aluminum?

Tinplate plate is not actually aluminum, but a steel with a tin coating. Although it is different from aluminum, like aluminum, tinplate plate is also a recyclable material. Let's learn more about tinplate plate and aluminum.

Recycling and utilization of tinplate plate:

Tinplate plate is usually used to make packaging containers such as cans. Although it has "iron" in its name, it is actually a steel coated with a thin layer of tin. This material has a high recycling rate in Europe, with about 78% of steel being recycled. This shows that tinplate sheet plays an important role in recycling resources.

Recycling and utilization of aluminum:

In contrast, aluminum is another common metal material that is also recyclable. In the UK, about 79% to 73% of aluminum is recycled. The recycling rate of aluminum materials is also considerable, making a positive contribution to environmental protection.

What is tinplate plate?

Tinplate plate is not a pure aluminum product, but a steel with a tin-plated surface. Its main component is low-carbon steel, and the outer layer is coated with a very thin layer of tin (Tin), which is also the origin of the name of tinplate sheet. The role of tin is to provide corrosion protection and prevent steel from rusting due to direct contact with air or moisture.

Tinplate sheet production process

The production process of tinplate sheet involves evenly covering the cold-rolled steel substrate with a layer of tin through electroplating or hot-dip coating. This layer of tin not only prevents the iron substrate from rusting, but also has a certain ductility, which can improve the processing performance of tinplate plate. After tinning, the steel sheet can be further processed into various shapes such as cans, bottle caps, food containers, etc.

Tinplate sheet has a wide range of uses

Due to its high strength, strong corrosion resistance and good processability, tinplate sheet is widely used in food and beverage packaging, as well as chemical products, pharmaceutical packaging and other fields, especially products that need to maintain the stability of the contents for a long time. Common ones include food cans, biscuit boxes, paint buckets, etc.

What is aluminum?

Aluminum is a lightweight metal material with the chemical symbol Al, which is widely used in many fields such as construction, transportation, packaging, etc. Aluminum is an element with a very abundant content in the earth's crust. Due to its low density, excellent electrical and thermal conductivity, and excellent corrosion resistance, it has become a key material in various industries.

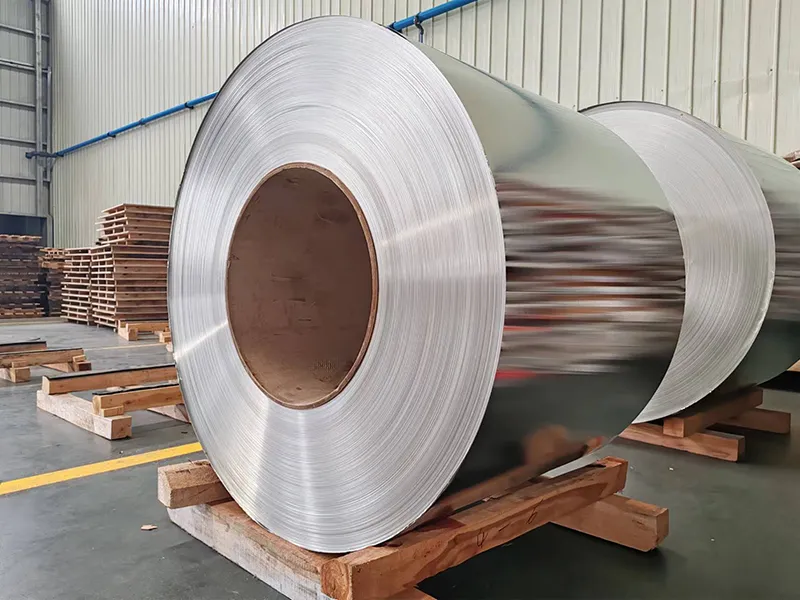

Production process

The production process of aluminum involves the mining and refining of aluminum ore, usually by electrolysis to extract aluminum from bauxite. Unlike the manufacturing process of steel, the smelting of aluminum is carried out by high-temperature electrolysis, which makes the production process of aluminum more energy-consuming. After smelting, aluminum can be made into plates, pipes, sheets or other structural parts, which are used in various industrial manufacturing and packaging products.

Wide range of uses

Due to the advantages of aluminum such as lightness, corrosion resistance and strong plasticity, it is widely used in aerospace, automobile manufacturing, building materials, food and beverage packaging and other fields. Common aluminum packaging products include aluminum cans, aluminum foil, food packaging bags, etc.

What is the difference between tinplate sheet and aluminum?

Although tinplate sheet and aluminum are widely used in the packaging field, there are significant differences between the two in terms of composition, performance, processing technology and application scenarios. The following will analyze the differences between tinplate sheet and aluminum in detail from multiple angles.

Material composition

The main body of tinplate sheet is low-carbon steel with a layer of tin on the surface. Its core material is iron, which makes tinplate plate have high strength and durability, but its anti-corrosion performance mainly depends on the protection of the tin layer. Once the tin layer is damaged, the iron substrate is easily oxidized when exposed to the air, causing rust.

Aluminum is a pure metal with relatively stable chemical properties and a dense aluminum oxide protective film is easily formed on the surface. This oxide film can effectively prevent further oxidation reactions, so aluminum is much more corrosion-resistant than tinplate sheet, and can withstand most corrosive environments even without an additional coating.

Physical properties

● Weight: The density of aluminum is only 2.7 g/cm³, which is much lower than the density of tinplate plate (the density of steel is about 7.85 g/cm³). Therefore, aluminum products are much lighter than tinplate sheet, and aluminum has obvious advantages in situations where lightweight is required. For example, in the production of beverage cans, aluminum cans are more suitable for large-scale production and transportation due to their lightness.

● Strength: The strength of tinplate sheet is higher than that of aluminum, especially when it is impacted by external forces, tinplate sheet is less likely to deform. Therefore, tinplate sheet is more suitable for packaging occasions that require higher mechanical strength, such as the storage and transportation of canned foods or industrial chemicals. Aluminum is more suitable for packaging that does not require high strength but is sensitive to weight, such as beverage cans, food foil, etc.

● Ductility: Aluminum has good ductility and is easier to process into various complex shapes during the molding process. Relatively speaking, tinplate plate has poor ductility, but with proper processing technology, it can still be made into complex packaging forms.

Corrosion resistance

The corrosion resistance of tinplate sheet depends on the tin layer on the surface. Once the tin layer is mechanically damaged or worn, the iron substrate is easily rusted when exposed to the air. Therefore, when tinplate plate is used or stored for a long time, the integrity of the outer layer of tin must be maintained to prevent corrosion.

Aluminum has natural corrosion resistance. Even if the aluminum surface is slightly scratched or worn, it can quickly form an aluminum oxide film in the air to protect the aluminum substrate from further oxidation. In contrast, aluminum performs better than tinplate sheet in humid or acidic environments, which makes aluminum packaging have advantages in some occasions with high corrosion protection requirements.

Processing technology

The production of tinplate plate requires a complex tinning process, and attention should be paid to the protection of the tin layer during processing to avoid damaging the surface layer and causing a decrease in corrosion resistance. In addition, tinplate plate is relatively rigid during the molding process, making it difficult to make fine bends or complex shapes.

Aluminum is more flexible to process. Due to its good ductility, aluminum can be easily processed into thin sheets, cans or other complex packaging shapes through a variety of processes such as cold rolling, stamping, and stretching. The molding process of aluminum products is relatively simple, with high production efficiency, and no additional processing such as tin plating is required.

Application areas

Tinplate sheet is often used for packaging that requires strength and impact resistance, such as canned foods, chemical products, and paint buckets. Its high strength and good sealing make tinplate plate very suitable for storing air-sensitive items, especially canned foods that are stored for a long time.

Aluminum is widely used in beverage cans, food packaging, pharmaceutical packaging, and cosmetic containers. The lightness and corrosion resistance of aluminum products make them very suitable for fast-moving consumer goods and packaging that requires lightweight.

Recyclability

Both tinplate sheet and aluminum have good recycling performance, but the recycling process of the two is slightly different. The recycling of tinplate sheet mainly depends on the steel recycling system, and steel products can be remade after smelting. Aluminum is easier to recycle and there is almost no loss of material properties during the recycling process. The energy consumption of recycling aluminum is much lower than that of producing primary aluminum, so the environmental value of aluminum is more prominent in this regard.

Price Factor

The production cost of aluminum is relatively high, especially due to its high energy consumption in the smelting process, so the price of aluminum is generally higher than that of tinplate sheet. However, the lightweight characteristics and corrosion resistance of aluminum make it cost-effective in certain application scenarios. For example, although the unit price of aluminum beverage cans may be higher than that of tinplate cans, its transportation costs and environmental recycling advantages make up for the difference in material costs.