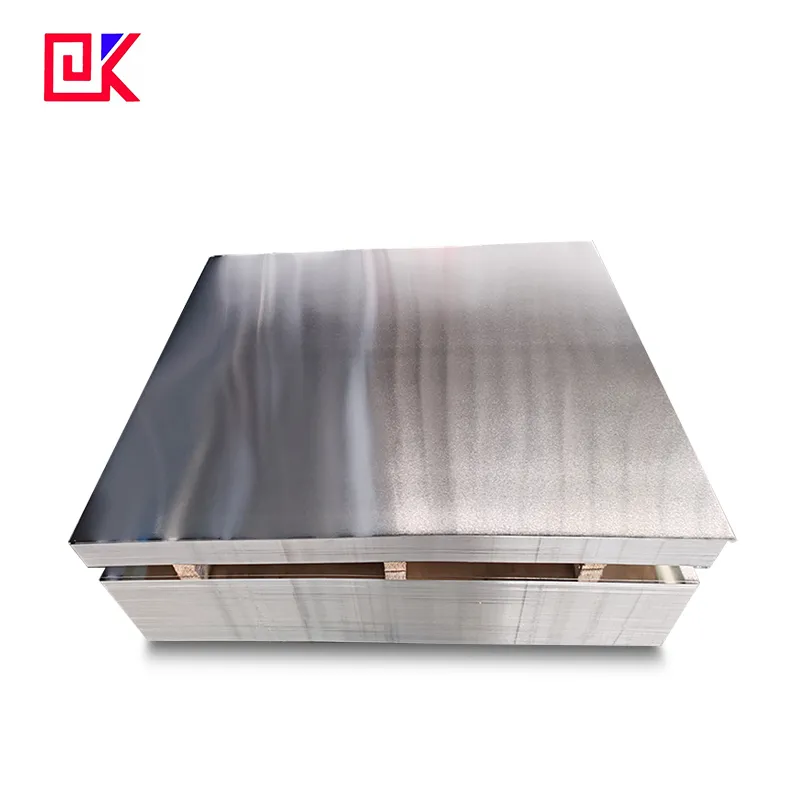

Tinplate plate is a metal material widely used in the packaging of various products, especially in the food, beverage, cosmetics and other industries. People's understanding of tinplate sheet often stays on its packaging function and material itself, but few people have in-depth discussions on the question of "what color is tinplate sheet". In fact, the color of tinplate sheet is not only related to its production process, but also affects its performance and appearance in packaging, protection and other aspects.

This article will start from the composition, process characteristics and appearance of tinplate sheet, and analyze in detail what the color of tinplate sheet is and the meaning behind these colors.

What color is tinplate sheet?

To understand the color of tinplate sheet, you first need to understand its basic composition. Tinplate sheet is a material with low-carbon steel as the base material and a layer of tin coated on the surface of steel, so it is also called tin-plated thin steel sheet. Its basic structure is steel base material + tin coating, so the color of tinplate sheet is mainly determined by the material of these two parts and their surface treatment.

Color of steel substrate

As the main material of tinplate plate, low carbon steel itself has the natural color of metal, usually showing a silver-gray or iron-gray metallic luster. This color of the steel surface comes from the essential properties of its iron element, and usually has a strong reflective effect. However, since steel is easy to oxidize and rust, it is difficult for a simple steel substrate to maintain this luster for a long time.

Color of tin coating

The outside of tinplate sheet is covered with a layer of tin, which not only gives tinplate sheet better anti-corrosion properties, but also greatly affects the color of tinplate sheet. Tin itself is a silvery-white metal, which is relatively soft and smooth, and can give the surface of tinplate sheet a bright silver-white color. Therefore, without other surface treatment, tinplate sheet usually presents a bright silver-white color with good metallic texture.

What factors affect the color of tinplate plate?

Although tinplate plate usually appears silvery-white or silver-gray, its color may change due to many factors in actual applications. These factors include material processing, type of surface coating, degree of oxidation, etc.

Influence of tinning process

The color of tinplate sheet is first affected by the tinning process. When manufacturing tinplate sheet, tin is usually coated on the steel surface by electroplating or hot-dip coating. These two different tinning processes may have a subtle effect on the color of tinplate sheet.

● Electroplating process

Electroplating tin is a process that deposits tin evenly on the steel surface by electrolysis. This process can make the tin layer more uniform, thin and smooth, usually giving the tinplate sheet a bright silvery white color. The surface reflective effect of electroplating tin is more obvious, and the color is closer to the original color of the metal.

● Hot-dip tinning process

Hot-dip tinning is to immerse the steel substrate in molten tin liquid so that its surface is evenly covered with a layer of tin. The tin layer thickness of this process is usually larger, and the surface may be slightly rough. Because hot-dip tinning may produce some tiny surface textures or particles during the cooling process, the surface gloss of this tinplate sheet is relatively low, the color is closer to grayish white or silvery gray, and the brightness is slightly inferior to electroplating tin.

The effect of tin layer thickness on color

The color of tinplate sheet is also affected by the thickness of its tin layer. Generally, the thicker the tin layer, the brighter the surface color of the tinplate plate, and the more obvious the silver-white color. This is because the thick tin layer can better cover the color of the steel substrate itself, reducing the color changes caused by minor defects or oxidation of the steel.

Conversely, if the tin layer is thinner, the color of the substrate may be faintly visible at certain angles or lighting conditions, causing the color of the tinplate sheet to be more silver-gray rather than bright silver.

The influence of surface treatment and coating

In addition to the basic tinning process, the surface of the tinplate plate can also be treated in a variety of ways, such as coating with protective paint, printing patterns, etc., which may significantly change its color performance.

● Transparent or translucent protective paint

In some cases, the surface of the tinplate plate is coated with a layer of transparent or translucent protective paint. This layer of paint not only enhances the anti-corrosion properties of the tinplate sheet, but also changes its surface gloss and color effects. If a transparent paint is used, the silver-white or silver-gray color of the tinplate sheet is still clearly visible, but the color may appear softer due to the refraction of light. If a translucent paint is applied, a light hue, such as a slight yellow or blue, will be added to the surface of the tinplate sheet, making it appear to have a changing color effect under different lighting conditions.

● Color coating and printing

The appearance of the tinplate sheet can be enhanced by printing or spraying a color coating. In many food and beverage packaging, we often see colorful tinplate sheet cans, the surface of which has been printed to give it a variety of colors. At this time, the metallic color of the tinplate sheet is covered, and the color depends entirely on the ink or coating used.

It is worth noting that this color coating and printing is often not only for aesthetics, but also for a certain protection, extending the life of the tinplate sheet during use.

Effect of oxidation and time

Although the tinplate sheet has good anti-corrosion properties, the tin layer on its surface may oxidize in some extreme environments or after long-term use. The color of the oxidized tinplate sheet surface will gradually change, and the tin layer may lose its original luster, appearing dull grayish white, and may even have slight yellow spots or rust spots.

Although this color change does not immediately affect the basic performance of tinplate sheet, visually, oxidized tinplate sheet often loses its original brightness and metallic texture.

How does the appearance of tinplate plate affect the color?

In addition to changing the color of tinplate plate through different processes and surface treatments, the appearance characteristics of tinplate plate itself also determine its color performance under different lighting conditions.

Reflective properties of metal

Because the surface of tinplate plate is composed of metal tin, its reflective properties are very obvious. Under natural light or strong light, the surface of tinplate plate can reflect a lot of light, making it look very bright, and even showing a flashing effect at certain angles. This strong reflective property makes tinplate sheet very advantageous when displaying product or brand image because it can attract consumers' attention.

Differences in gloss

The gloss of tinplate plate is mainly determined by its surface treatment. Untreated tinplate surface usually has a high gloss and presents a bright silvery white. Tinplate sheet coated with protective paint, color coating or printing will have a reduced gloss. Especially for tinplate plates with matte paint, the reflective effect of the surface is reduced, and the color tends to be softer gray or colorful.

Texture and details

The tiny texture or granularity on the surface of the tinplate plate will also affect its color performance. For example, the surface of the tinplate sheet treated by hot-dip tinning process may have slight textures, which will affect the direction of the reflected light under different angles of light, making the color look uneven or even changing the color depth. In contrast, the surface of the tinplate sheet produced by the electroplating process is smoother and the color is more uniform.

What is the significance of the color of the tinplate plate?

The color of the tinplate plate is not only an appearance feature, but in fact, in many cases, it also carries functional significance. Tinplate sheets of different colors can convey different functional information or usage scenarios:

● Silvery white basic protection

Silver-white is the most common color of tinplate sheet. This color not only shows the metal characteristics of the tinplate plate, but also reflects the tin layer protection on its surface. This bright appearance usually means that the tinplate plate has good anti-corrosion properties and is suitable for long-term storage of food, beverages and other products.

● Identification function of color coating

In many packaging designs, colored tinplate plates are used to convey brand information and product categories. Different colors are not only visually appealing, but also help consumers quickly identify product types or flavors.

● Functional distinction between matte and glossy

The surface treatments of matte and glossy tinplate plates often represent different usage scenarios. Glossy surfaces are often used for packaging of high-end products because they have a higher visual impact, while matte surfaces are more suitable for products that require a low-key or stable appearance.