As the main material widely used in a variety of packaging materials such as food, beverages, cosmetics, and medicines, the technical requirements of tinplate printing are to pursue higher production efficiency and environmental sustainability while maintaining high quality. As a process that has long dominated tinplate printing, whether offset printing technology will still occupy a mainstream position in 2025 is a topic of common concern within and outside the industry.

To answer the question "Will tinplate printing still use offset printing technology in 2025?", we first need to have a deep understanding of the role and advantages of offset printing technology in tinplate printing, and at the same time consider the performance of this traditional printing technology in the face of various new technological challenges.

This article will conduct a detailed analysis of the working principle of offset printing technology, its application advantages in tinplate printing, its comparison with other printing technologies, and the challenges faced by offset printing technology, in order to explore the actual application of this technology in 2025.

What is the working principle of offset printing technology?

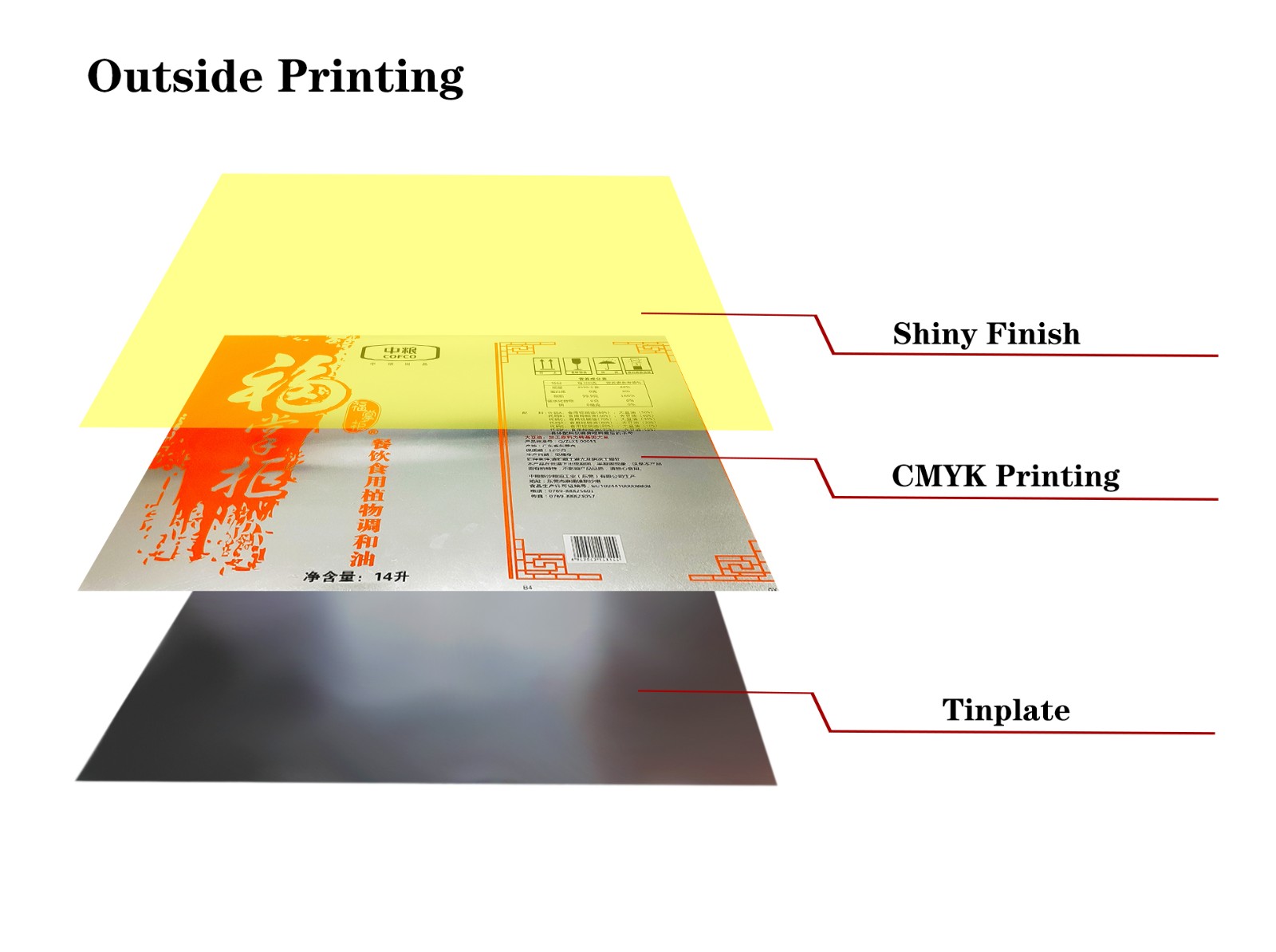

Offset printing is a lithographic printing technology based on the principle of oil-water incompatibility. Its core steps include transferring the printed image from the printing plate to the rubber cloth cylinder, and then the rubber cloth prints the image on the substrate. Compared with other printing technologies, offset printing can achieve high-precision, high-definition image printing and is suitable for mass production.

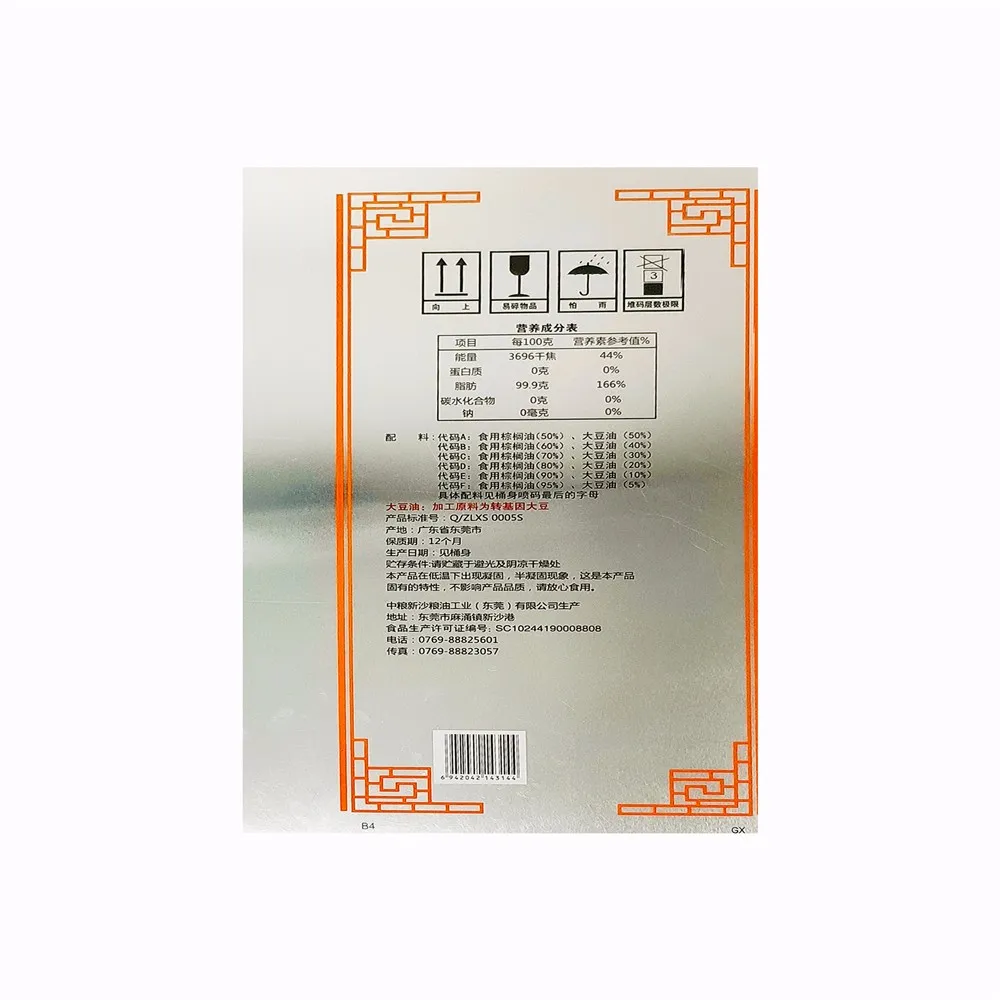

In tinplate printing, offset printing has strong adaptability and can achieve a variety of complex printing effects on metal surfaces. Since the surface of tinplate plate is smooth and easy to color, the ink transfer process of offset printing is relatively simple. Using offset printing technology, colorful and layered patterns can be printed on the surface of tinplate plate, thus achieving high-quality visual effects. The successful application of offset printing technology has made tinplate plate one of the indispensable materials in the packaging industry.

What are the advantages of offset printing technology in tinplate printing?

To determine whether offset printing technology will still be widely used in 2025, we must first understand its main advantages in tinplate printing, which have always been an important reason for the continuation of offset printing technology.

1. High printing precision

Offset printing technology is known for its high precision and is particularly suitable for tinplate packaging that requires clear and fine image printing. Many tinplate packaging application scenarios (such as food, beverages, and cosmetics) require that the outer packaging not only has a protective function, but also needs to have an attractive appearance design for consumers. The offset printing process can faithfully display complex designs, bright colors, and delicate patterns, which is essential for the packaging of high-end products.

2. Strong color expression

Offset printing technology can achieve rich color expression through the mixing of CMYK four-color inks (cyan, magenta, yellow, and black). Whether it is a beverage can that needs to show bright colors or a cosmetic box that needs to reflect a simple and elegant style, offset printing can achieve a high level of color reproduction through multiple color overprinting and layered printing. For brands that want to attract consumers' attention through packaging, the accuracy and richness of color expression are crucial, and offset printing technology has a significant advantage in this regard.

3. Suitable for large-scale production

Another key advantage of offset printing technology is that it is very suitable for large-scale production. Due to the high production efficiency of the offset printing process, a large amount of packaging materials can be printed at one time, reducing the unit printing cost. Therefore, offset printing is widely used in mass-produced products such as tinplate cans and beverage cans, and can balance the relationship between high-quality printing and production costs.

4. Strong stability

In long-term applications, offset printing technology has been proven to be a stable and mature printing process. Because the printing plates of this technology are durable, can withstand repeated use, and the failure rate of the equipment is low, this process can ensure the stability of long-term mass production. Therefore, offset printing still plays an irreplaceable role in scenarios where large-scale tinplate packaging printing is required.

Comparison of offset printing with other printing technologies: Who is the best?

Although offset printing technology has many advantages, with the continuous advancement of printing technology, other emerging printing methods are also challenging the status of offset printing. In 2025, new technologies such as digital printing and screen printing have gradually entered the field of tinplate printing. By comparing these technologies, it is better to judge whether offset printing is still suitable for tinplate printing.

1. Digital printing

Digital printing is a printing technology that has developed rapidly in recent years. Its main feature is that it does not require the production of printing plates, and directly transfers images from computers to printing presses, which can achieve short-run production and personalized customization. Compared with offset printing, digital printing has higher flexibility in small-batch production and can quickly adjust patterns and colors. In addition, digital printing is suitable for variable data printing, which can achieve different patterns on each printed product.

However, in terms of mass production, the efficiency of digital printing is still not comparable to offset printing, and the color expression and image fineness of digital printing are not as good as offset printing in some complex designs. Therefore, for tinplate printing, which is mass-produced and requires high precision, offset printing still has an advantage.

2. Screen printing

Screen printing is a printing technology that transfers ink to the substrate through a screen. Compared with offset printing, the ink layer of screen printing is thicker, which is suitable for printed products with high requirements for image durability. However, the disadvantage of screen printing is that its color expression is poor and it is difficult to achieve complex and multi-color patterns.

Although screen printing excels in some specific application scenarios, offset printing is still the preferred technology for most tinplate packaging that requires rich colors and complex designs.

What are the challenges facing offset printing technology?

Although offset printing technology has many advantages in tinplate printing, it also faces some challenges that may affect its future application in the market.

1. Increasingly stringent environmental protection requirements

In the context of today's enhanced environmental protection awareness, volatile organic compounds (VOCs) produced by solvent-based inks in offset printing processes are considered to be unfavorable factors for the environment. Although the emergence of UV inks and water-based inks in recent years has improved this problem, many companies are still using traditional solvent-based inks. The increasingly stringent environmental regulations have put forward new requirements for offset printing technology, and companies need to seek more environmentally friendly solutions, which may lead some printing manufacturers to gradually turn to printing technologies with higher environmental requirements.

2. Equipment cost and maintenance

Offset printing equipment is relatively complex and has high maintenance costs. Compared with digital printing, offset printing requires a series of tedious steps such as plate making, ink mixing, and equipment maintenance. With the technological advancement and cost reduction of digital printing equipment, the economic advantages of offset printing in some small and medium-sized production scenarios are gradually weakening.

3. Poor production flexibility

Offset printing technology performs well in mass production, but its flexibility is relatively poor for personalized and small-batch production needs. In contrast, digital printing can quickly respond to market demand and perform short-run printing or personalized customization, which makes digital printing a challenge to offset printing in some areas.

Customized Metal Packaging Solutions for Your Business

Looking for customized metal packaging that reflects your brand’s quality? Foshan Dekai Metal Packaging Co., Ltd. is the trusted manufacturer for premium aerosol cans, tinplates, and other packaging solutions. We offer a variety of customization options, from printing designs to tailored product sizes, to ensure your packaging meets your exact specifications. With competitive pricing, low minimum orders, and quick production times, we provide everything you need to succeed in today’s competitive market. Contact us for a quote or more details on our customized services.