Tinplate plate, as an important packaging material, is widely used in industries such as food, beverages, chemicals, and daily necessities. In everyday life, common items like cans, food containers, and paint cans are often made of tinplate. However, many people may not be aware that the thickness of tinplate plate plays a crucial role in different applications.

The thickness of tinplate plate not only determines the product's strength and durability, but also affects its corrosion resistance, processing difficulty, and application range. This article will detail tinplate plate thickness specifications, measurement methods, and the specific uses of tinplate plate of different thicknesses in practical applications.

How thick is tinplate plate?

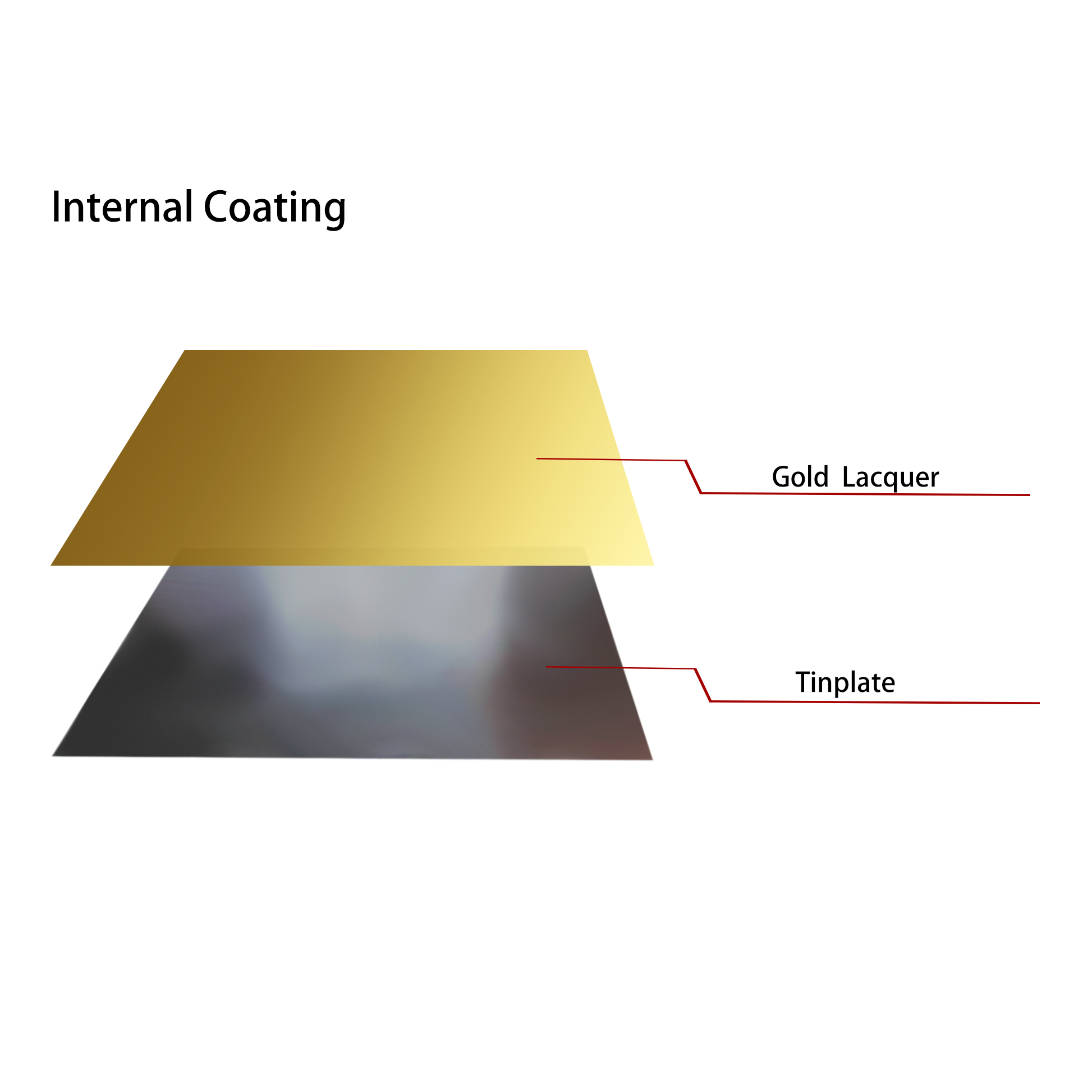

Tinplate plate is a tin-plated material applied to the surface of mild steel, primarily used to prevent oxidation and corrosion. According to international standards, tinplate plate thickness is typically measured in millimeters (mm). In industrial applications, tinplate plate thickness generally ranges from 0.13 mm to 0.50 mm, with different thicknesses suiting different packaging needs and applications.

1. Tinplate Thickness Range

Tinplate thickness varies depending on its intended use. Generally, thinner tinplate is used for packaging that requires lightness and flexibility, while thicker tinplate is used for product packaging that requires greater strength and durability. Specific thickness ranges are as follows:

• Thin tinplate: 0.13 mm to 0.20 mm

• Medium-thick tinplate: 0.21 mm to 0.30 mm

• Thick tinplate: 0.31 mm to 0.50 mm

2. Thickness Units and Measurement Methods

In industry, tinplate thickness can be accurately measured using a micrometer or precision thickness gauge. Precise thickness control is crucial to ensuring the product's corrosion resistance and mechanical properties. Furthermore, tinplate thickness directly affects its processing ease and molding quality, so careful consideration should be given to the product's design requirements when selecting the tinplate thickness.

What are the applications of tinplate of different thicknesses?

Tinplate applications of varying thicknesses:

1. Thin Tinplate (0.13mm to 0.20mm)

1.1 Food and beverage cans

1.2 Biscuit boxes and candy packaging

1.3 Cosmetics and perfume containers

2. Medium Tinplate (0.21mm to 0.30mm)

2.1 Food cans

2.2 Paint cans and chemical packaging

2.3 Can caps and closures

3. Thick Tinplate (0.31mm to 0.50mm)

3.1 Large paint cans and chemical containers

3.2 Construction and decorative materials

3.3 Industrial packaging containers

Different tinplate thicknesses have different mechanical properties and processing characteristics. Therefore, specific tinplate thicknesses have specific uses in packaging and industrial applications.

1. Thin Tinplate (0.13mm to 0.20mm)

Thin tinplate is primarily used for packaging products that require lightweighting. Due to its thinness, thin tinplate plate is easier to process into complex shapes, while also reducing material consumption and transportation costs during production. Typical applications of thin tinplate plate include:

1.1 Food and Beverage Cans

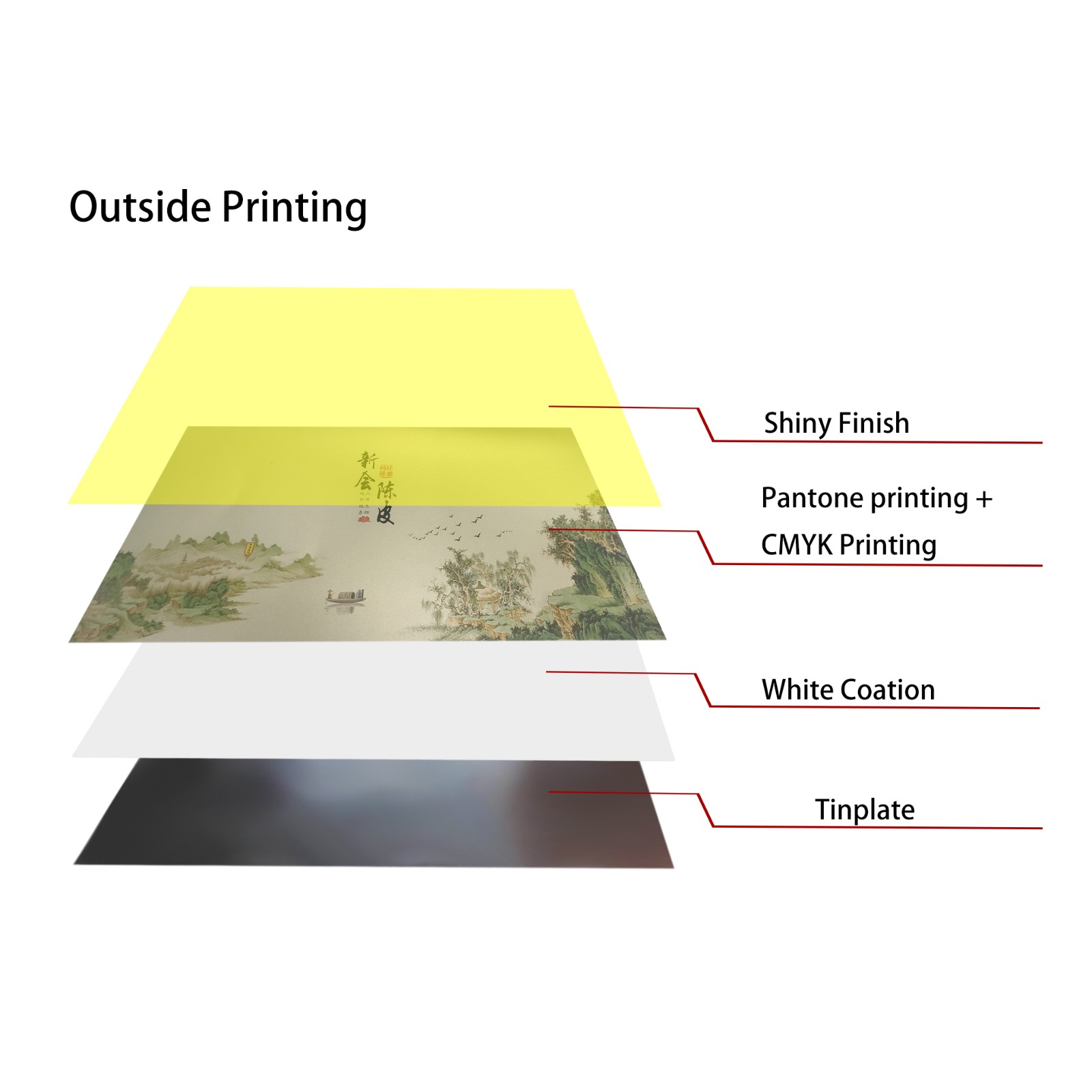

Thin tinplate sheet is widely used in the manufacture of food and beverage cans, particularly in the beverage industry, such as carbonated drinks and beer cans. Its lightweight and excellent sealing properties make it an ideal choice for beverage packaging. Its lightweight nature not only helps reduce shipping costs but also makes it easier for consumers to carry and use. Furthermore, its surface coating effectively isolates oxygen and moisture, extending the shelf life of food and beverages.

1.2 Biscuit and Candy Packaging

The lightweight and corrosion-resistant nature of thin tinplate sheet makes it ideal for food packaging, such as biscuit and candy boxes. These packaging not only ensures the quality of the contents but also offers a certain aesthetic appeal, often enhanced through printing and decorative techniques. Since biscuits and candies require less mechanical strength, thinner tinplate plate is sufficient.

1.3 Cosmetic and Perfume Containers

Some high-end cosmetic and perfume bottle caps are also made from thin tinplate plate. Thin tinplate plate allows for precise stamping and forming, resulting in a smooth, textured surface, making it ideal for products requiring aesthetically pleasing packaging. Furthermore, tinplate plate's printability allows manufacturers to create intricate designs, enhancing the product's market appeal.

2. Medium-Thickness Tinplate Sheet (0.21 mm to 0.30 mm)

Medium-thickness tinplate sheet is common in industrial applications because it combines strength with good workability. Medium-thickness tinplate sheet allows for complex processing and printing while maintaining sufficient strength. The following are typical uses for medium-thickness tinplate sheet:

2.1 Canned Food Packaging

Canned food packaging is one of the primary applications for medium-thickness tinplate sheet. Canned foods typically require extended storage periods and must withstand temperature fluctuations and external pressure, placing high demands on the packaging material's strength and sealing properties. Medium-thick tinplate sheets provide sufficient strength to withstand the stresses of transportation, storage, and processing, ensuring that the contents remain contaminated during long-term storage.

2.2 Paint Cans and Chemical Packaging

Paints and chemicals are often corrosive, so their packaging materials must possess both excellent corrosion resistance and strength. Medium-thick tinplate sheets excel in this application, as their tin layer effectively prevents corrosive substances from corroding the steel substrate. Compared to thinner tinplate sheets, medium-thick tinplate sheets offer greater impact resistance, providing additional protection during transportation and storage.

2.3 Canned Bottle Caps and Closures

Middle-thick tinplate sheets are commonly used for bottle caps and closures in many canned food or beverage packaging. This is because bottle caps must not only provide a good seal but also possess sufficient strength to maintain deformation during opening and closing. Medium-thick tinplate sheets meet these requirements. Furthermore, their plasticity allows for a variety of bottle cap designs to suit different product packaging needs.

3. Thick Tinplate Sheet (0.31mm to 0.50mm)

Thick tinplate sheet offers high strength and rigidity, making it suitable for industrial packaging that must withstand high forces or harsh environments. Its primary applications are in the chemical, construction, and large container manufacturing industries, where high strength is required. The following are typical uses for thick tinplate sheet:

3.1 Large Paint Cans and Chemical Containers

Thick tinplate sheet is particularly suitable for manufacturing large paint cans, chemical containers, and storage tanks. These products must hold corrosive liquids for extended periods and withstand significant impact and pressure during transportation. Thick tinplate sheet's high strength and excellent corrosion resistance provide reliable protection for their contents in these harsh environments.

3.2 Construction and Decoration Materials

In the construction and decoration industries, thick tinplate sheet is often used to create architectural components with high aesthetic requirements, such as roof coverings and drain pipes. Tinplate sheet's smooth surface and ease of coating complement architectural designs, while its thickness provides strength and durability.

3.3 Industrial Packaging Containers

Some large mechanical parts, tools, or industrial products requiring long-term storage also use thick tinplate sheets as outer packaging. Thick tinplate sheets not only provide excellent pressure resistance but also protect the contents from environmental factors such as moisture and oxidation.

How to Choose the Right Tinplate Sheet Thickness?

When selecting tinplate sheet thickness, manufacturers and designers need to make decisions based on the specific requirements of the product. Choosing the right tinplate sheet thickness ensures both safety and cost-effective packaging. The following factors should be considered:

1. Product Characteristics

The contents of the package are a key factor in selecting tinplate sheet thickness. For example, beverage cans require lightness, while paint cans require greater strength. Therefore, different products have different packaging requirements and require different tinplate sheet thicknesses.

2. Storage and Transportation Conditions

If the product needs to be shipped long distances under harsh transportation conditions or needs to be stored for long periods of time, thicker tinplate sheets can provide additional protection and reduce the risk of damage. For lightweight packaging, thinner tinplate sheets can help reduce weight and lower shipping costs.

3. Manufacturing Cost

Thicker tinplate sheets offer greater strength and durability, but their manufacturing and processing costs are relatively high. Therefore, choosing the right thickness requires balancing product packaging needs with economical costs to avoid wasting resources due to excessive packaging.

Can I request samples before placing a bulk order?

Yes, we offer free samples or low-cost sample kits depending on your needs. Testing our tinplate quality, print clarity, and aerosol can durability before placing a full order gives you peace of mind. If you're considering purchasing from a Chinese factory, Dekai makes the decision easier with clear communication, fast sampling, and custom quotes.