Tinplate plate and carton are two important packaging materials in today's packaging market, each with its own unique advantages. Tinplate plate is known for its durability, moisture resistance, corrosion resistance and exquisite printing effect, while carton is widely used in many industries because of its lightness, environmental protection, low cost and convenient printing.

As the demand of the packaging market continues to increase, the difference between these two packaging materials in printing has also attracted more and more attention. So, what is the difference between tinplate printing and carton printing? This article will analyze the differences between these two printing methods step by step around the printing process, material characteristics, application scenarios and other aspects.

Why are tinplate printing and carton printing processes different?

What are the characteristics of the process flow of tinplate printing?

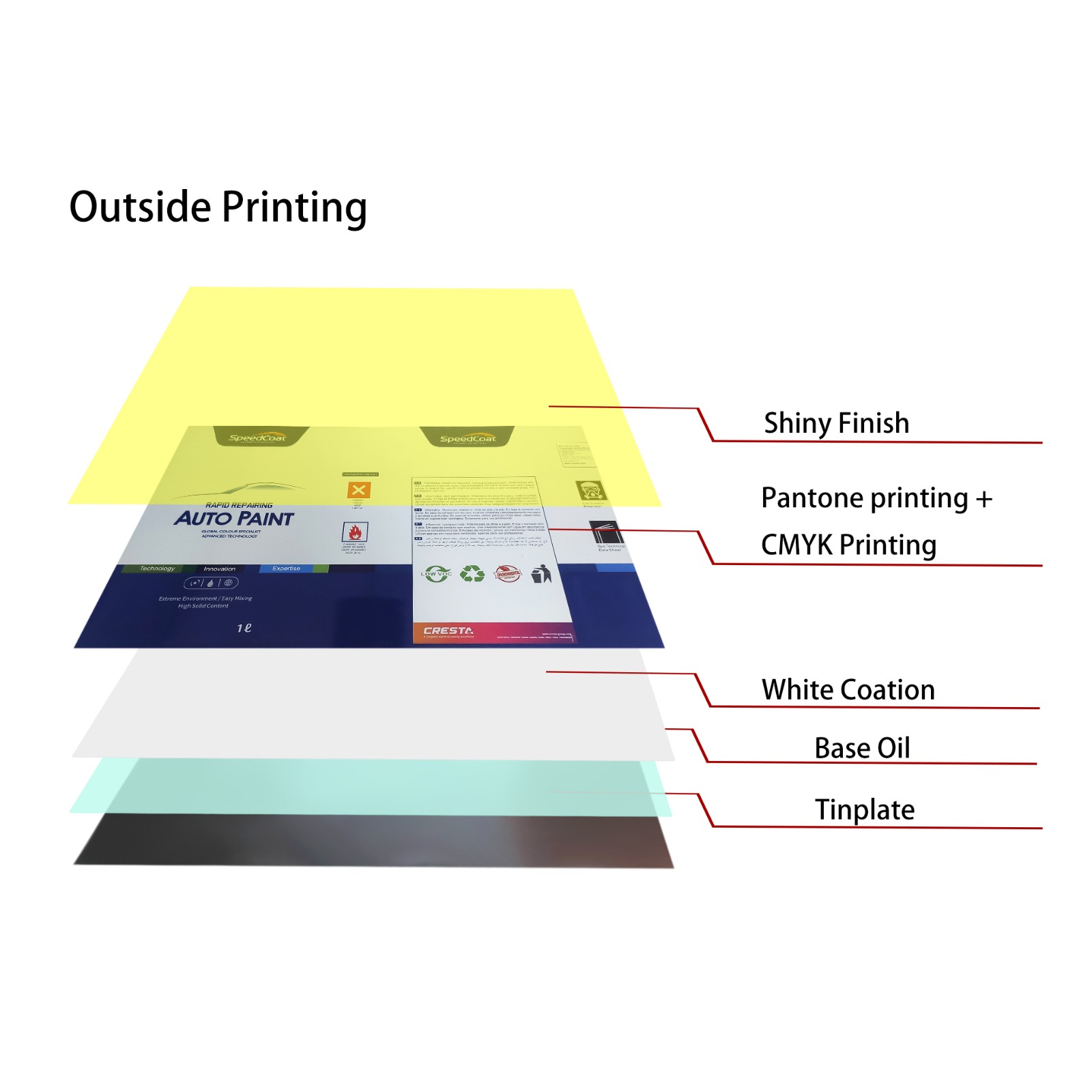

Tinplate printing is a complex process that usually requires multiple processes to complete. First of all, tinplate printing requires surface treatment of tinplate to ensure that the ink can adhere firmly. During this process, a degreaser is generally used to clean the surface to make it clean and free of impurities to ensure the clarity and durability of subsequent printing. Next, the printing process will apply a layer of primer on the tinplate surface to enhance the adhesion of the surface ink, which is not common in carton printing.

During the printing process, tinplate plates usually use special UV inks, which cure quickly at high temperatures to form colorful and waterproof patterns. After printing, baking, drying and laminating are required to increase the durability and wear resistance of the printing. Finally, die-cutting, folding and welding are required to make the printed tinplate into finished packaging boxes.

Is the carton printing process relatively simple?

In contrast, the process flow of carton printing is relatively simple, mainly divided into two methods: flexographic printing and offset printing. Flexographic printing is the most commonly used technology in carton printing. It uses flexible plates to achieve efficient printing at low pressure and is usually suitable for mass-produced packaging boxes. Offset printing can provide more delicate patterns and is suitable for printing packaging boxes that require exquisite patterns. Carton printing does not require surface treatment and baking processes. The ink only needs to be directly applied to the surface of the carton, so the production efficiency is high and the cost is low.

In general, tinplate printing requires a more complex process and has higher requirements for equipment; while carton printing has a relatively simple process and is more suitable for rapid mass production.

What is the difference between tinplate and carton in terms of material properties?

How does the material of tinplate plate affect the printing effect?

Tinplate plate is a metal material with high strength and good corrosion resistance. It can provide a hard surface and is not easy to deform when printing. Because the surface of tinplate is smooth, the ink can be evenly adhered and show a high gloss. The pattern of tinplate printing is extremely clear and bright in color, which is especially suitable for displaying a high-end brand image. Its waterproof, moisture-proof and insect-proof properties allow the printed pattern to remain colorfast for a long time, and it can maintain a lasting visual effect even in a humid or sun-exposed environment.

Is the carton material susceptible to environmental influences?

Cartons are mainly made of corrugated paper and gray board paper. Their printing surface is rough, the ink absorbs strongly, and they are easily affected by humidity and temperature. Therefore, the pattern printed on the carton is softer in color, does not have a metallic luster, and is easily deformed by moisture in a humid environment. Since the paper itself has low strength, long-term placement may cause the pattern to wear or fade. In addition, the waterproof and moisture-proof properties of cartons are poor, so they are not suitable for long-term storage or display packaging materials.

What inks are suitable for the printing of tinplate plates and cartons?

Why is UV ink commonly used in tinplate printing?

Tinplate printing usually uses UV ink, which has the characteristics of bright colors, strong adhesion and high temperature resistance. Under ultraviolet light, UV ink will quickly solidify to form a solid pattern, ensuring the durability of printing quality. The corrosion resistance and weather resistance of UV ink make the printed pattern not easy to fall off, which is suitable for the printing needs of hard materials such as tinplate. Due to the high-temperature curing characteristics of UV ink, the printed iron box can be sterilized and treated at high temperature without affecting the quality of the packaging material.

What inks are commonly used for carton printing?

Carton printing mostly uses water-based inks and solvent inks. Water-based inks have become the mainstream choice for carton printing because of their strong environmental protection and non-toxicity. Water-based inks have good fluidity and fast drying speed, which are suitable for high-speed printing. Solvent inks have higher color saturation and are suitable for packaging printing that requires higher color effects, but they are not as environmentally friendly as water-based inks.

Unlike tinplate UV inks, water-based inks do not require UV curing and can be directly air-dried, so the printing process is simpler and suitable for soft materials such as cartons. However, water-based inks have relatively weak adhesion and are greatly affected by humid environments, and are prone to fading or peeling.

What is the cost difference between tinplate printing and carton printing?

Why is tinplate printing more expensive?

The cost of tinplate printing is usually higher because of its complex process and high equipment requirements. Surface treatment of tinplate, use of UV ink, baking and curing will increase production costs. In addition, the procurement cost of tinplate materials is also higher than that of cardboard, and the subsequent die-cutting and welding processes make the overall printing cost more expensive. Tinplate printing is often used for high-end, customized product packaging, such as food, cosmetics and luxury goods packaging, which have very strict requirements on quality and appearance.

Why is carton printing suitable for large-scale production?

In contrast, carton printing has a lower cost, the carton material itself is cheap, and the production process is relatively simple. It does not require high temperature treatment or UV curing, and is suitable for rapid mass production. Carton printing has fewer process flows and less equipment investment, so the cost is relatively controllable, and it is suitable for large-scale, low-cost product packaging. For example, logistics, express delivery, daily necessities and other industries use carton packaging in large quantities because it is cheap, light and easy to use.

What is the difference between tinplate plate and carton printing in terms of environmental protection?

How is tinplate printing environmentally friendly?

Tinplate printing has certain advantages in terms of environmental protection. As a metal material, tinplate is highly recyclable, and the used iron box can be recycled and reused, which helps to reduce resource waste. Although UV ink is used in the printing process, it basically does not release harmful substances after drying, so it has little impact on the environment. In addition, the durability of tinplate plate allows it to be used repeatedly, further reducing the need for disposable packaging.

Is carton printing more environmentally friendly?

Carton printing is mainly based on water-based ink, which is more environmentally friendly, and the carton itself is easy to degrade, which meets the needs of green and environmentally friendly packaging. Carton materials can be recycled and made into pulp, reducing resource consumption. However, the durability of cartons is relatively poor, especially after multiple transportation or long-term storage, so although it has advantages in environmental protection, the life cycle of cartons is shorter than that of tinplate plates.

What occasions are suitable for tinplate plates and carton packaging?

Is tinplate plate packaging suitable for high-end products?

Due to its exquisite printing effect and durability, tinplate plate packaging is usually used for high-end products and product packaging that focuses on brand image. For example, products such as food cans, cosmetic boxes, and tea cans that have high requirements for packaging quality often choose tinplate plates to enhance the grade and texture of the products. In addition, tinplate plates have good sealing properties and are suitable for products that need to be stored for a long time.

Is carton packaging more suitable for daily consumer goods?

Carton packaging is usually used for daily consumer goods packaging and transportation packaging, such as express packaging, home appliance packaging, and electronic product packaging. The lightness and low cost of carton make it suitable for mass-produced fast-moving consumer goods. Although the printing effect of carton is not as exquisite as tinplate, it has significant advantages in protecting products and reducing packaging costs. It is the preferred packaging method for many companies.