06-05/2025

Food and beverage liquid products

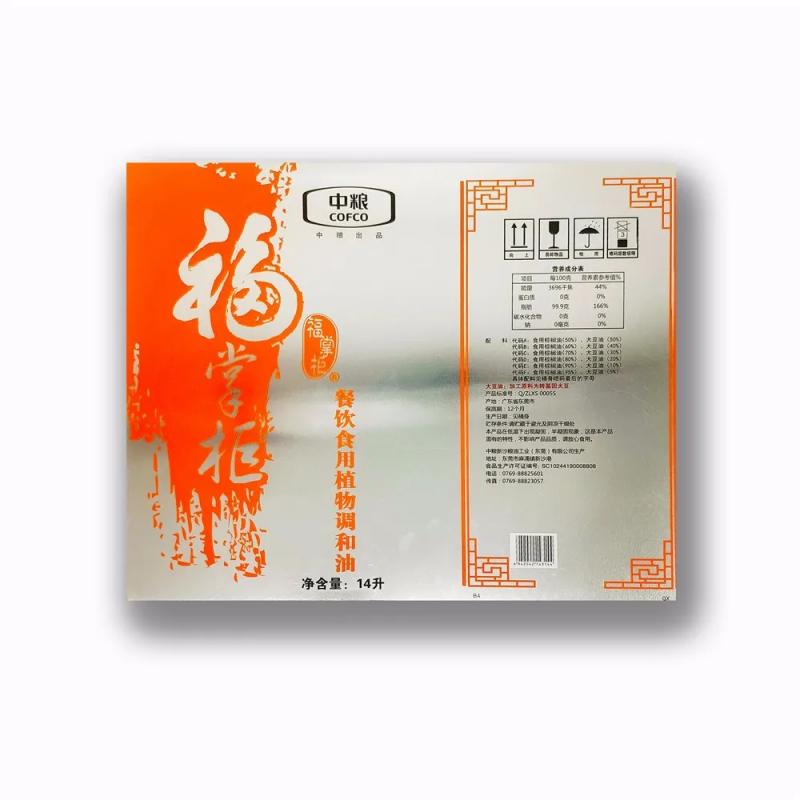

Food and beverage liquid products are the most common application areas of tinplate can packaging. Liquid products such as juice, milk, carbonated beverages, and edible oil can be better protected and preserved when using tinplate can packaging.