As a common form of food packaging, tinplate candy tins are not only durable and safe, but also have become one of the popular choices in the market because of their unique appearance and printing effects. However, in order to improve the aesthetics of candy tins, enhance their durability, extend their shelf life, etc., manufacturers usually paint the surface of tinplate sheets. So, why do candy tins made from tinplate sheets need to be painted? What important role does painting play in the function and appearance of candy tins?

This article will explore this issue in depth, answer the necessity of painting tinplate sheets, analyze the different types of painting treatments and their multiple effects on candy tins.

Why do tinplate candy tins need to be painted?

The painting treatment of tinplate sheets is a key process that not only affects the appearance of the packaging, but also has a profound impact on the performance, hygiene and market performance of the packaging. Why is the surface treatment of candy tin so important? We can analyze it from the following aspects.

Can painting enhance the anti-corrosion properties of candy tins?

As a metal material, although the surface of tinplate sheet has been tinned, it may still undergo oxidation reaction if it is exposed to air and moisture for a long time, especially in a humid environment. Therefore, in order to improve the corrosion resistance of tinplate candy tin, spray painting has become an essential step.

Spray painting can not only effectively isolate the contact between oxygen and moisture in the air and the surface of tinplate sheet, but also prevent acidic substances or other food ingredients from corroding metal materials to a certain extent. This is very important for extending the service life of candy tin and ensuring the stability of packaging materials. Spray painting is especially suitable for candies and desserts that need to be stored for a long time, which can effectively prevent tinplate sheet from corrosion and rust due to changes in the external environment.

Can spray painting improve the beauty of candy tin?

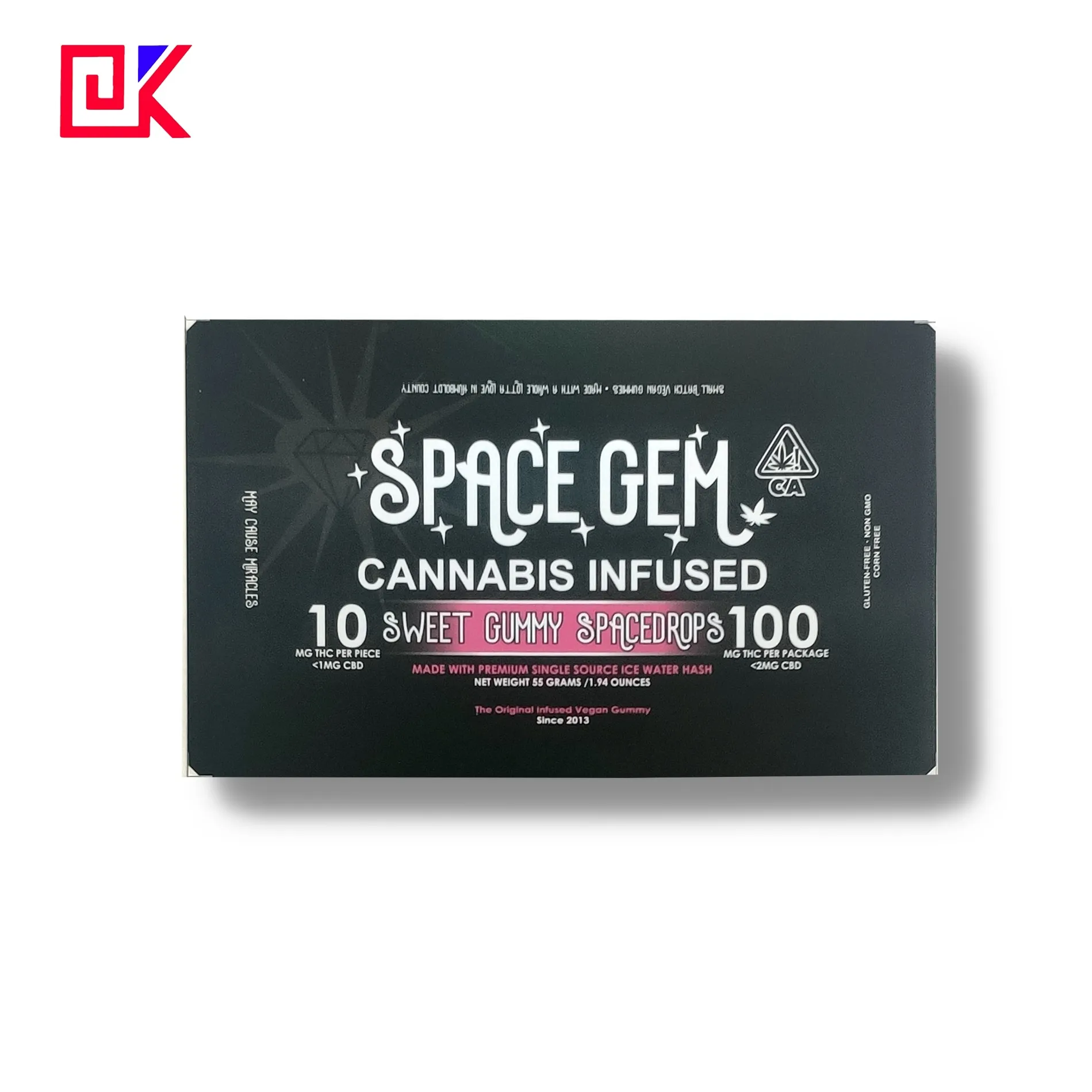

In addition to practical functions, the appearance design of candy tin is also crucial to the market competitiveness of the product. Spray painting can provide candy tin with a smoother and brighter surface, which not only improves the visual effect, but also enhances the consumer's tactile experience. Spray painting can make the color of candy tin more vivid and stable, which is helpful for brand recognition and product promotion.

After spraying the surface of candy tin, many candy manufacturers will add various exquisite patterns and texts through printing technology to further enhance the attractiveness of the packaging. Whether it is traditional metallic tones or popular color coatings, they can attract consumers' attention and increase their desire to buy products.

Can spraying improve the durability of candy tin?

Candy tin usually needs to undergo long-term transportation, stacking and handling, so the friction, impact and other external forces on its surface cannot be ignored. Spraying can effectively enhance the surface hardness of the can body and improve its scratch and wear resistance. The spray coating can not only provide additional protection, but also reduce the exposed metal part of the tinplate sheet surface due to wear, thereby avoiding rust and corrosion.

In addition, spraying can also improve the UV resistance of candy tin, preventing the coating from fading or damage due to long-term sunlight exposure. This is of great significance to ensure that the can body remains beautiful and intact during long-term transportation and storage.

What are the effects of spraying type on candy tin?

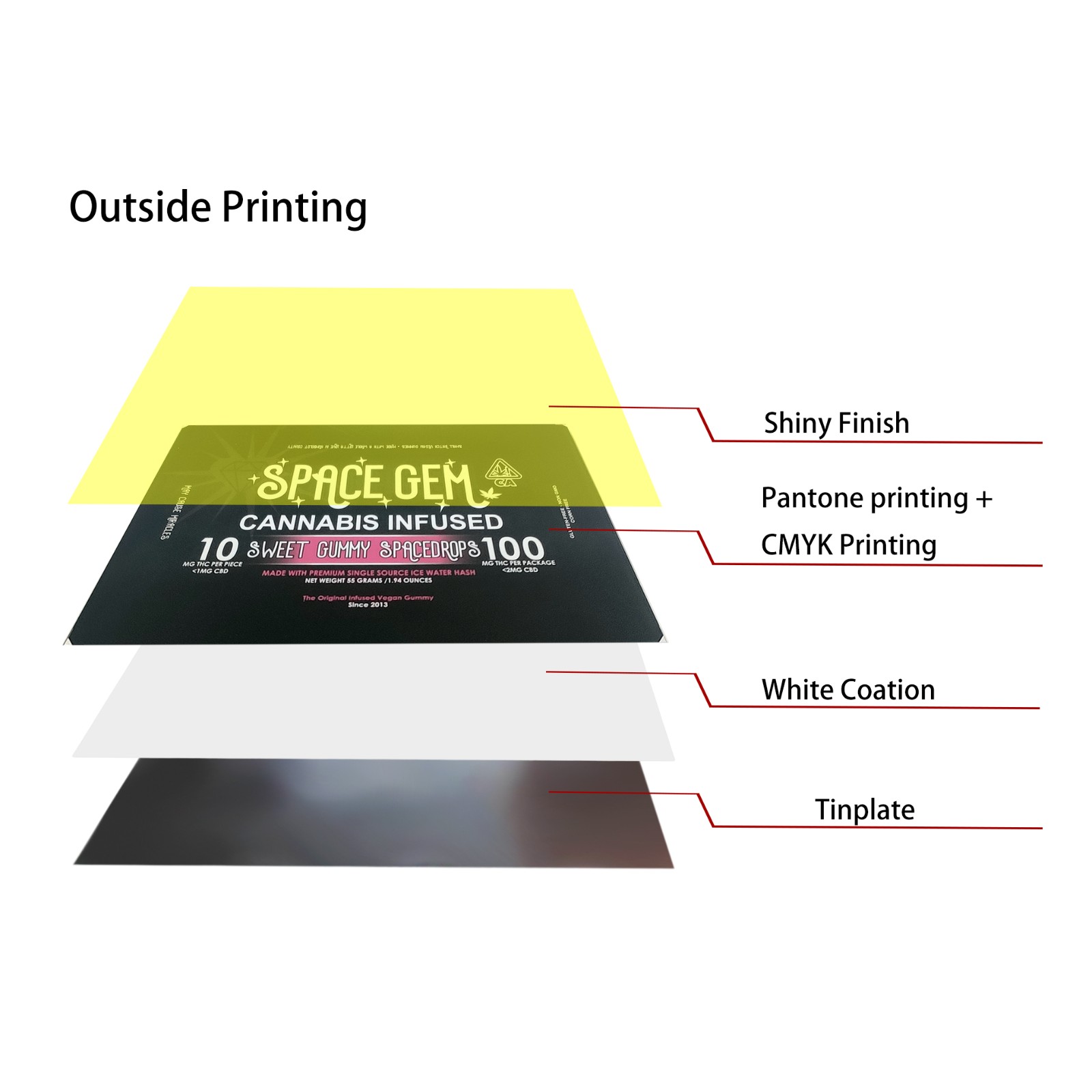

For candy tin, painting is not only about improving the appearance, it also involves different types of coatings and technologies. Different types of painting will have different effects on the performance, safety of use and environmental protection of candy tin.

1. Type of painting: Which coatings are more suitable for candy tin?

Candy tin is usually painted with food-grade coatings, which must meet strict food safety standards. Common food-grade coatings include epoxy resin coatings, polyurethane coatings, etc., which can provide excellent protection without reacting with the food in the tinplate sheet.

Epoxy resin coatings are widely used in tinplate sheet food packaging due to their strong adhesion, corrosion resistance and high temperature resistance. Polyurethane coatings have high wear resistance and glossiness, which can provide more lasting protection for tinplate sheets.

2. Tinplate sheet: How to choose the right painting method?

There are two common processes for tinplate sheet painting: electrostatic spraying and thermal spraying. Electrostatic spraying uses paint particles to adhere evenly to the metal surface under the action of an electric field, while thermal spraying melts the paint at high temperature and then sprays it onto the metal surface. Different spraying processes can be selected according to the specific needs of candy tin.

The advantages of electrostatic spraying are uniform coating, high paint utilization, and smooth surface; thermal spraying can provide a more high-temperature and corrosion-resistant coating, suitable for combating harsh environmental conditions. The choice of the two processes will be determined by the purpose, storage conditions, and required durability of the candy tin.

3. What is the impact of spray paint thickness on candy tin?

The thickness of the spray paint directly affects the durability and performance of candy tin. A thicker spray paint layer can provide better protection for the tinplate sheet and prevent corrosion and wear of the candy tin by the external environment. A thinner spray paint layer is more flexible and is suitable for tinplate sheets that require high appearance but do not require excessive durability.

However, too thick a coating may cause the paint to crack or peel, affecting the aesthetics and durability of the tinplate sheet packaging. Therefore, a reasonable spray paint thickness is very important and needs to be adjusted according to the material, storage environment and usage requirements of the candy tin.

Can spray painting improve the hygienic safety of candy tin?

As a part of food packaging, the hygienic condition of candy tin directly affects the health of consumers. The spray paint layer can not only prevent the invasion of external pollutants, but also prevent the candy tin from reacting with harmful substances in the air and maintain the safety of the environment inside the can.

Some special spray paint materials also have antibacterial effects, which can effectively reduce the growth of bacteria and further improve the hygienic safety of food. For tinplate sheet products that are stored for a long time, especially candies with special shelf life requirements, spray painting is particularly important.

Can spray painting improve the airtightness of candy tin?

Airtightness is crucial to the quality of candy tin, especially in candy products that are sensitive to moisture and oxygen, it is crucial to maintain the sealing of the packaging. Spray painting can improve the airtightness of candy tin to a certain extent, prevent air and moisture penetration, thereby effectively extending the shelf life of candy and maintaining its taste and freshness.

How to choose the right tinplate sheet spray painting method?

Choosing the right spray painting method not only needs to consider the appearance requirements of the candy tin, but also needs to be decided based on the actual usage scenario, environmental conditions and the characteristics of the candy. Tinplate sheet manufacturers should decide based on the following factors:

● Storage environment of candy: High temperature, high humidity and other environments require a more durable coating.

● Type of candy: Choose the right spray painting material and process for the characteristics of the candy.

● Appearance requirements of the packaging: Choose different colors and printing effects according to the brand positioning.