Tinplate cans are an indispensable material in the packaging industry and are widely used in the packaging of food, beverages, chemical products and daily necessities. Tinplate plays an important role in various packaging needs due to its excellent strength, plasticity and corrosion resistance. However, the material properties of tinplate itself are not enough to fully meet the protection requirements in practical applications. Therefore, various types of coatings are applied to the surface of tinplate cans to enhance their functionality, extend their service life, and improve their appearance.

This article will systematically explain the various types of coatings applied to tinplate cans and their specific functions, and help understand the key role of these coatings in tinplate cans packaging.

What is tinplate cans coating?

The tin coating on the surface of tinplate (i.e. tin-plated steel plate) can provide a certain degree of protection, but in order to enhance its corrosion resistance, improve food safety and improve visual effects, various coatings are usually applied to the outside or inside of tinplate cans. These coatings are mainly divided into the following categories:

1. Anti-corrosion coating

2. Decorative coating

3. Functional coating

Different types of coatings on tinplate cans each play a specific role in the packaging field. Reasonable selection and use of these coatings can effectively improve the performance and service life of tinplate cans packaging.

What are the functions of different coatings on tinplate cans?

There are many types of coatings on the surface of tinplate cans. The specific coating used usually depends on the purpose of the product, storage environment, usage scenario and appearance requirements.

Common coating types for tinplate cans:

1. Anticorrosion coating

1.1 Epoxy coating

1.2 Polyester coating

1.3 Acrylic coating

2. Decorative coating

2.1 Paint coating

2.2 Printing coating

2.3 Varnish coating

3. Functional coating

3.1 Antibacterial coating

3.2 Anti-ultraviolet coating

3.3 Waterproof coating

1. Anticorrosion coating

Anticorrosion coating is the most important type of coating in tinplate cans packaging. Its main purpose is to protect the surface of tinplate cans from oxidation and corrosion in the external environment and extend the service life of the packaging. The packaging of food, beverages and chemical products must have good anticorrosion properties, otherwise it will cause the contents to deteriorate or the packaging to fail.

1.1 Epoxy coating

Epoxy resin is a coating material widely used inside tinplate cans, mainly used for the packaging of food cans, beverage cans and other products. It has extremely strong corrosion resistance and can effectively block the contents from direct contact with metals, preventing acidic or alkaline substances in food from corroding metals. In addition, epoxy resin coating also has excellent adhesion and chemical stability, will not affect the taste and quality of food, and is a commonly used anti-corrosion coating material in the food industry.

1.2 Polyester coating

Polyester coating is also a common anti-corrosion coating for tinplate cans, usually used for the inner wall of beverage cans. It is characterized by good transparency and wear resistance, and is suitable for packaging environments with long-term contact with acidic or carbonated beverages. Polyester coating also has excellent mechanical properties and can withstand high temperature and high pressure sterilization during canning production to ensure the integrity of the packaging.

1.3 Acrylic coating

Acrylic coating performs well in the anti-corrosion protection of tinplate cans, especially for some special food packaging, such as cans containing high-acid fruits. Acrylic coating has excellent acid resistance and can avoid corrosion of the can body by highly acidic contents. In addition, acrylic coating has a certain degree of flexibility, which can maintain integrity when the can body is slightly impacted or pressure changes, and prevent coating damage from causing metal corrosion.

2. Decorative coating

Decorative coating is mainly used on the outside of tinplate cans. Its function is not only to provide beautiful visual effects, but also to protect the surface of the can to a certain extent. Decorative coating is often used to enhance the market appeal of products and provide brands with more personalized packaging designs.

2.1 Paint coating

Paint coating is the most common decorative coating on the outer surface of tinplate cans. It makes the packaged products more eye-catching on the shelves through different colors, patterns and glossiness, increasing consumers' desire to buy. Paint coating not only plays a decorative role, but also improves the antioxidant properties of tinplate cans and delays the erosion of the metal surface by the external environment. Common paint coatings include matte, gloss, pearlescent and other effects, which can be selected according to the product positioning and brand style.

2.2 Printing coating

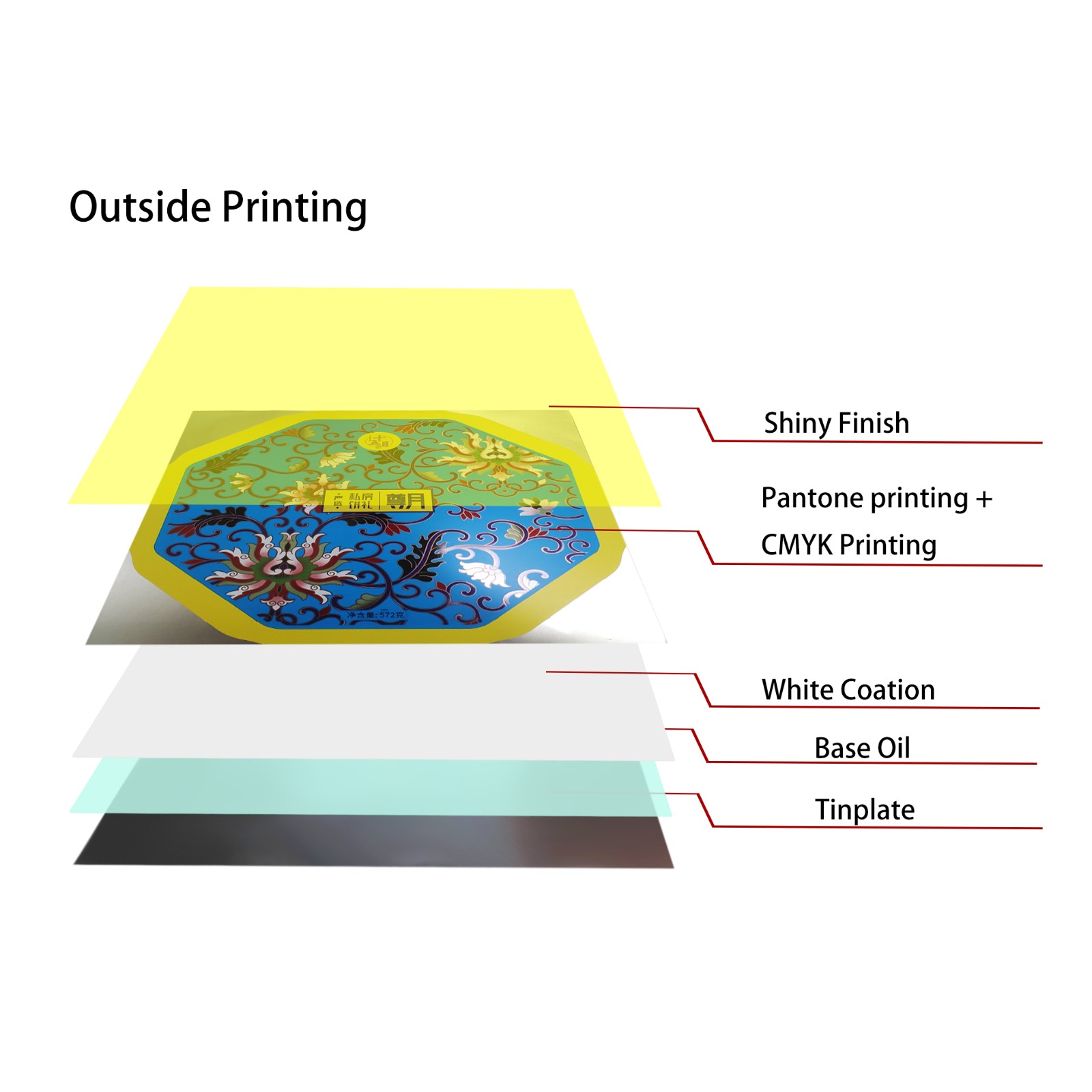

Printing coating is an indispensable part of tinplate cans packaging, which is used to print product information, brand logos and design patterns on the surface of the can. Printing coating is usually composed of multiple layers of ink, which can present rich visual effects in the superposition of different colors and layers. In addition, the printed coating also has certain wear resistance and corrosion resistance, which can effectively protect the integrity of the can body during transportation and storage.

2.3 Varnish coating

The varnish coating is a transparent protective coating for tinplate cans, which is usually applied to the outermost layer of the printed pattern to protect the decorative pattern. The varnish coating can increase the wear resistance of the packaging and prevent the printed layer from falling off due to external friction or impact. At the same time, the varnish coating can also increase the glossiness of the packaging surface, making the product look more upscale.

3. Functional coating

The functional coating is designed to improve the performance of tinplate cans packaging in specific environments, such as enhancing its waterproof and moisture-proof properties or giving it antibacterial functions. Such coatings are usually used in some special applications to meet specific packaging needs.

3.1 Antibacterial coating

Antibacterial coatings are gradually gaining attention in food and pharmaceutical packaging. By adding antibacterial agents or materials with antibacterial effects to the coating, this coating can effectively inhibit the growth of bacteria and microorganisms on the packaging surface and extend the shelf life of the product. In some tinplate cans packaging applications that require a high hygienic environment, antibacterial coatings are a key means to improve product safety.

3.2 Anti-UV coating

Anti-UV coating is mainly used for packaged products that are exposed to sunlight. This type of coating can effectively block ultraviolet radiation and prevent the food or beverage inside the tinplate cans from deteriorating or changing in flavor due to light. Anti-UV coating is very common in some transparent or translucent packaging designs, which can not only meet the display needs of the product, but also provide necessary protection.

3.3 Waterproof coating

Under certain environmental conditions, packaging may need to have certain waterproof properties, especially in humid storage environments or cold chain transportation. Waterproof coating can enhance the moisture resistance of tinplate cans and prevent moisture penetration from affecting the surface of the can or the quality of the contents.

Combination of different coatings on tinplate cans

In actual production, the coating of tinplate cans usually does not use only a single type of coating, but a combination of multiple coatings to achieve multiple protection effects. For example, a tinplate can of food cans may use epoxy resin coating on the inner wall to prevent corrosion, a printed coating on the outside to display brand information, and finally a layer of varnish coating to increase wear resistance and gloss. Through a reasonable combination of coatings, packaging manufacturers can customize the most suitable packaging solutions according to the needs of different products.

Quality control and safety standards of coatings

Since tinplate cans are mostly used in areas with high safety requirements such as food and beverages, quality control of coatings is crucial. Manufacturers must strictly abide by national and international safety standards for food packaging materials to ensure that coating materials do not contaminate the contents or affect the taste and quality of food.

At the same time, in the production process of tinplate cans, the coating coating process and curing treatment also need to be strictly controlled. The thickness, uniformity and adhesion of the coating directly affect the protective performance of the packaging. Usually, manufacturers use sophisticated testing equipment to conduct quality inspections on the coating to ensure that tinplate cans products meet relevant standards and requirements.

Foshan Dekai Metal Packaging Co., Ltd. stands out as a professional manufacturer of metal packaging products, including tinplate materials and aerosol cans. Our 50,000-square-meter factory is powered by advanced FUJI printing technology, enabling fast production with unmatched precision. We pride ourselves on delivering creative and functional packaging solutions at competitive prices, tailored to the specific requirements of wholesale buyers. Our streamlined processes and expert team ensure we consistently exceed expectations!