As an important packaging material, tinplate cans are widely used in many fields such as food, beverages, and cosmetics. Due to its superior corrosion resistance, good sealing and strong protective performance, tinplate cans have become the preferred packaging material for many consumer products. However, whether tinplate cans are suitable for liquid product packaging is still a concern for many manufacturers and consumers.

Liquid products have high requirements for packaging, and need to ensure product quality, preservation effect and convenience. Therefore, when choosing packaging materials, it is necessary to fully consider the advantages and disadvantages of tinplate cans. This article will discuss this issue in detail and analyze whether tinplate cans are suitable for packaging liquid products.

What are the characteristics of tinplate can packaging?

The structure and function of tinplate cans

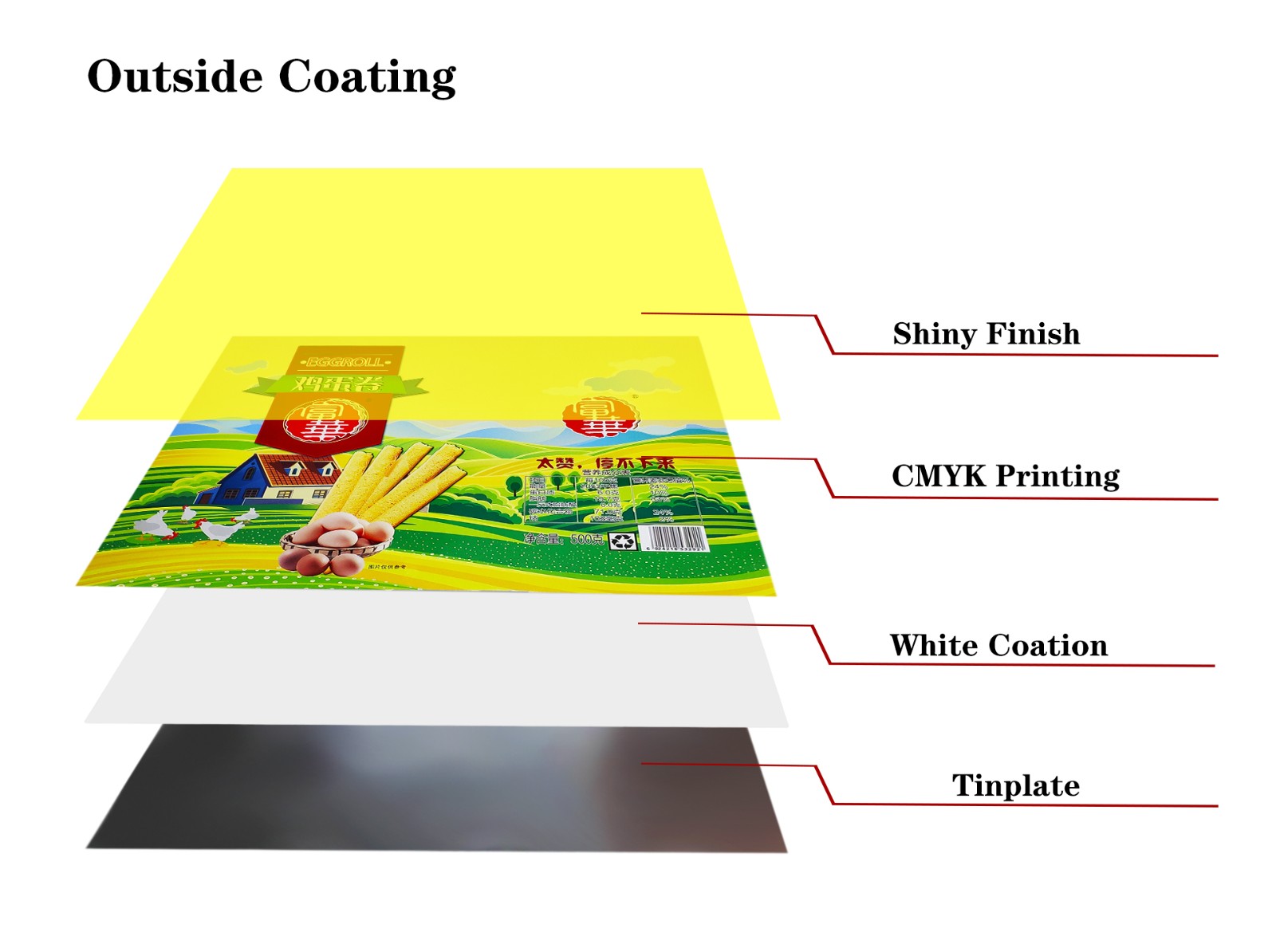

Tinplate cans are metal containers made of thin iron plates. Its outer layer is usually tinned to improve corrosion resistance and avoid metal corrosion caused by contact with air, moisture, sunlight and other factors. Its inner layer is often coated with an anti-corrosion coating, especially for the packaging of food, beverages and other products. The role of the inner coating is particularly important. It can prevent direct contact between liquid and metal, thereby preventing metal ions from penetrating into the liquid and ensuring the safety of the product.

The advantages of tinplate can packaging include durability, moisture and oxidation resistance, and recyclability. Due to its strong sealing, it can effectively isolate the outside air and moisture, and extend the shelf life of the product. At the same time, tinplate can packaging usually has good pressure resistance and is suitable for long-distance transportation and storage.

Requirements for packaging materials for liquid packaging

The packaging of liquid products needs to have certain anti-leakage, pressure resistance, corrosion resistance and oxidation resistance. Especially for liquid products with strong water, acidity or oiliness (such as beverages, juices, cooking oils, etc.), the packaging materials not only need to effectively protect the liquid, but also ensure that they will not react with the liquid to ensure the taste and quality of the liquid product.

Liquid packaging also needs to take into account convenience, especially the convenience of consumers when purchasing and using. Liquid products usually need to have the characteristics of easy opening and easy pouring, which puts higher requirements on packaging form and design.

Is tinplate can packaging suitable for liquid products?

Can tinplate can packaging effectively prevent liquid leakage?

The sealing performance of tinplate cans is one of its important advantages. Liquid packaging needs to have sufficient sealing to prevent liquid leakage and contamination. The design of tinplate cans usually includes a tight closed structure, which gives it a natural advantage in leak prevention. By adopting advanced sealing technology, tinplate cans can effectively prevent liquid products from leaking due to external pressure or temperature changes during transportation and storage, ensuring the safety of liquid products.

In addition, the compression resistance of tinplate cans also enables it to withstand the pressure during the storage of liquid products, avoiding deformation or breakage caused by external forces. Especially for some liquid products that need to be stored for a long time (such as edible oil, milk powder, etc.), the sealing and compression resistance of tinplate cans can effectively maintain their quality.

How is the preservation effect of tinplate cans on liquid products?

The preservation effect of liquid products often depends on the moisture-proof, oxygen-proof and UV-resistant capabilities of the packaging material. Tinplate cans have excellent moisture-proof and oxygen-proof capabilities, and can effectively prevent the damage of external air, moisture and sunlight to liquid products. For highly acidic liquids, such as juice, carbonated beverages, etc., the anti-corrosion coating on the inner layer of tinplate can packaging can prevent liquids from contacting metals, avoid adverse reactions, and thus maintain the original flavor and quality of the product.

In addition, the anti-ultraviolet ability of tinplate cans also provides a guarantee for the preservation of liquid products. Ultraviolet rays can cause chemical reactions in the ingredients of liquid products, reducing the quality of the products. Because tinplate cans are opaque, they can effectively isolate ultraviolet rays and extend the shelf life of liquid products.

Can tinplate cans prevent liquid products from spoiling?

Liquid products are particularly susceptible to factors such as temperature, light, and oxygen, and are prone to oxidation and corruption, especially when stored for a long time. Due to its good sealing, tinplate can packaging can effectively isolate oxygen in the air and prevent liquid products from reacting with oxygen, thereby reducing the risk of oxidation.

For example, when tinplate cans are used for liquid products such as juice, milk, and soy sauce, they can delay the loss of nutrients and flavors in the products, ensuring that the products maintain a good taste and nutritional value for a long time. For the food industry, shelf life is a crucial factor. The anti-oxidation, light-proof and moisture-proof properties of tinplate can packaging can effectively ensure the long-term stability of liquid products.

Which liquid products are suitable for tinplate can packaging?

Food and beverage liquid products

Food and beverage liquid products are the most common application areas of tinplate can packaging. Liquid products such as juice, milk, carbonated beverages, and edible oil can be better protected and preserved when using tinplate can packaging. Especially during long-term storage and transportation, tinplate can packaging can effectively prevent liquid leakage, oxidation and contamination, and extend the shelf life of the product.

For food liquid products, the inner coating of tinplate can packaging plays a key role, which can prevent liquids from reacting with metals and ensure the quality of the product. Taking juice as an example, the seamless design of tinplate cans can effectively prevent air penetration, thereby maintaining the freshness and taste of the juice.

Cosmetic and pharmaceutical liquid products

In addition to food products, cosmetic and pharmaceutical liquid products are also often packaged in tinplate cans. For example, some high-end perfumes, shampoos, skin care lotions and other liquid cosmetics often use tinplate can packaging. For pharmaceutical liquids, such as potions, oral liquids, etc., tinplate cans are also ideal packaging choices due to their sealing, antioxidant and corrosion resistance.

In these application scenarios, tinplate cans can not only protect the quality of liquid products, but also provide good visual effects. Many high-end cosmetic brands will choose custom-designed tinplate can packaging to enhance the luxury and market appeal of the products.

Industrial liquid products

In the industrial field, tinplate cans are also widely used to package certain liquid chemicals, paints, and detergents. These liquid products usually need to be packaged in corrosion-resistant and pressure-resistant containers to ensure safety during transportation and storage. The antioxidant and pressure resistance of tinplate cans just meet this demand.

What are the precautions for tinplate can packaging liquid products?

Quality issues of coating and sealing performance

When tinplate can packaging liquid products, the quality of coating and sealing performance must be ensured. Poor quality inner coating may cause direct contact between metal and liquid, which in turn affects the quality and safety of the liquid. Therefore, when choosing tinplate cans, companies need to choose coatings that meet food safety standards and conduct strict quality inspections to ensure the safety and reliability of the packaging.

In addition, the sealing performance of tinplate cans is the key to ensuring the quality of liquid products, especially in the case of long-term storage or transportation. For liquid products, the sealing must meet high requirements to avoid any air or moisture from entering.

Choose the right capacity and can type

When packaging liquid products, it is also necessary to choose the right capacity and can type according to the characteristics of the product. For daily consumer goods, such as beverages, juices, etc., tinplate cans are usually smaller in capacity, which is convenient for consumers to carry and use. For bulk products, such as edible oil, it is necessary to choose larger capacity tinplate can packaging to meet consumer needs.

High-Quality Aerosol Cans & Metal Packaging – Made in China

Looking for high-quality aerosol cans and metal packaging? Foshan Dekai Metal Packaging Co., Ltd. offers a comprehensive range of products to meet your packaging needs. From tinplate to top and bottom lid production, we ensure each unit is crafted with precision using advanced automation and the latest technology. With a focus on providing affordable pricing and customized solutions, we are your trusted supplier for bulk orders and wholesale purchasing. Get in touch for discounted quotes and discover how our products can elevate your packaging solutions.