07-02/2025

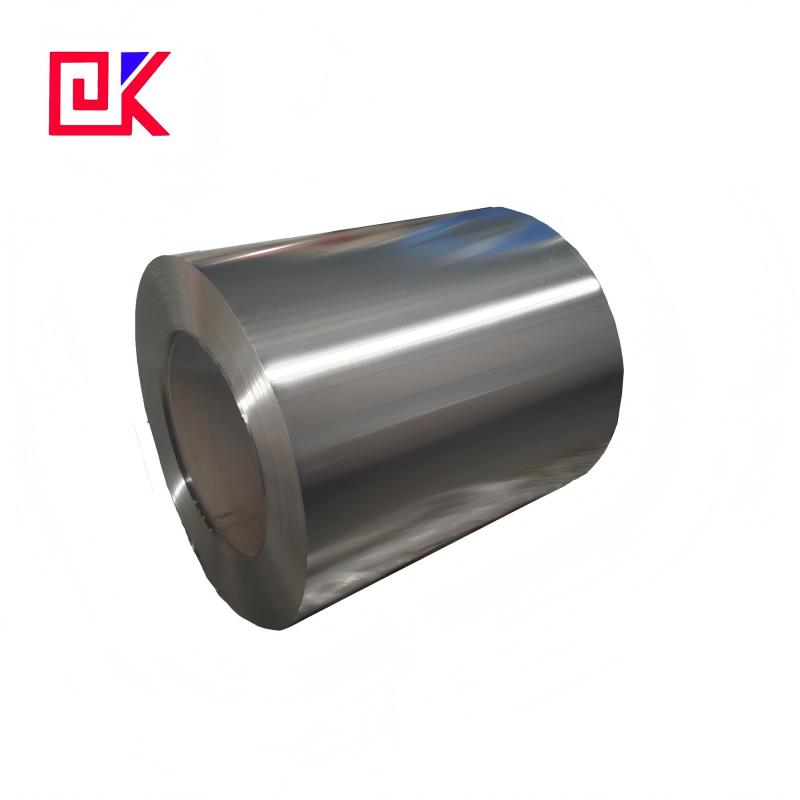

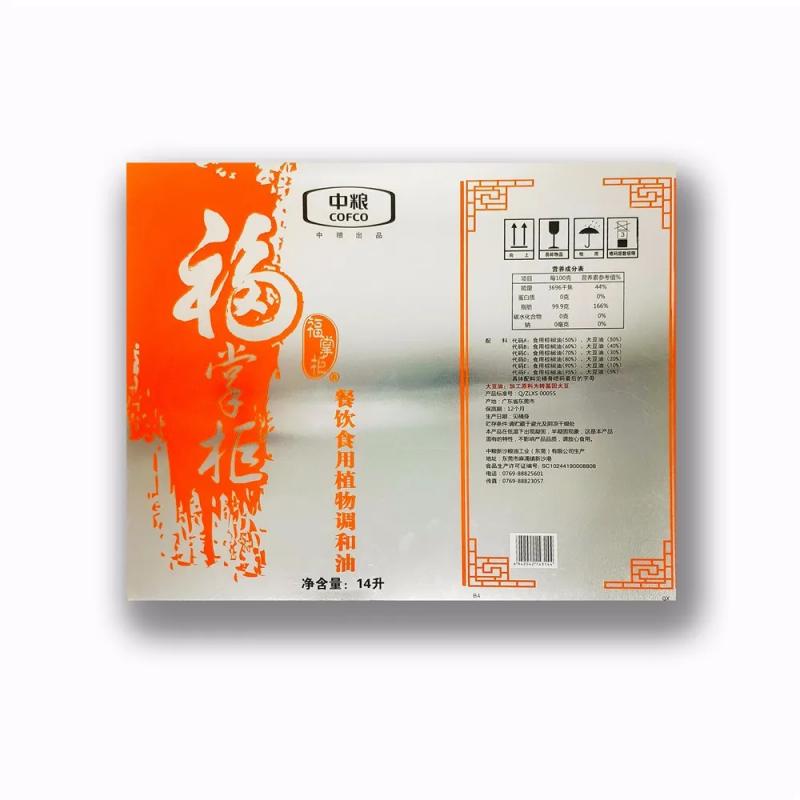

The tin-plated layer on the surface of tinplate plate can not only resist the erosion of air and moisture, but also prevent the metal from directly contacting food. Especially in acidic foods (such as canned fruit and canned tomatoes), the protective performance of tinplate plate is particularly important.