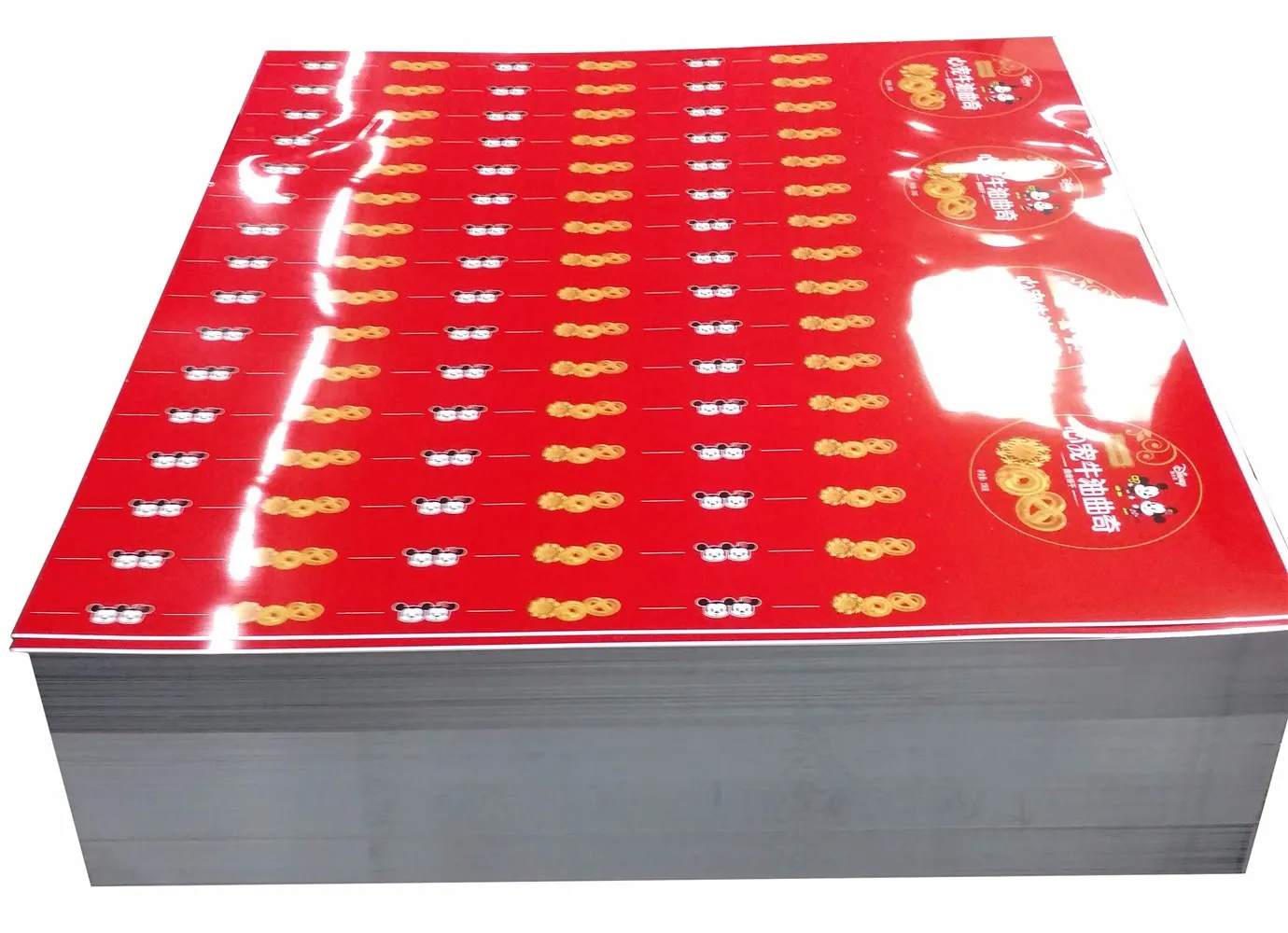

In the modern packaging industry, tinplate sheets are an important packaging material and are widely used in the packaging of various foods, beverages, cosmetics and industrial products. The printing process of tinplate sheets is particularly critical because it directly affects the appearance quality, brand image and consumer purchasing desire of the final product.

However, many people may not know how long it takes to print tinplate sheets. This issue involves many factors, from raw material preparation to printing process, to later drying and packaging, each link may have an impact on the time.

This article will discuss in detail the time required for tinplate sheet printing and the factors that may affect the printing cycle in this process, to help readers better understand the background of this complex process.

What factors are related to the time of printing tinplate sheets?

1. How does the complexity of printing affect the time?

Printing tinplate sheets is not a simple process, especially when it comes to complex pattern designs and colors, the time required will increase accordingly. Different printing methods, different pattern requirements, and the diversity of colors will directly affect the printing cycle.

Generally speaking, the more inks and the richer the colors used in the printing tinplate sheet process, the longer the printing time. For example, traditional four-color printing and high-precision pattern printing take significantly longer than single-color printing. This is because each color requires a separate printing process, and after each color is printed, a certain amount of drying time is required before the next color can be printed.

In addition, complex pattern designs or specific effects (such as highlights, shadows, gradient colors, etc.) require additional processes, further extending the production cycle. In some high-end packaging products, special treatments may also be required, such as embossing, hot stamping, lighting or local gloss effects, which will increase the overall printing time.

2. What is the relationship between the equipment conditions of the production line and the process flow?

The efficiency of the equipment, the advancement of the technology, and the configuration of the production line will have a significant impact on the speed of printing tinplate sheet. On some efficient and highly automated production lines, the printing speed of tinplate sheet will be faster and the time will be shorter. Especially in the preparatory work before printing (such as oiling, baking, pretreatment, etc.) and the later drying process, the configuration of the equipment and the maturity of the technology are crucial.

For example, the use of advanced digital printing technology can greatly improve production efficiency and reduce the time of printing tinplate sheet compared with traditional offset printing or screen printing. In addition, production lines with a high degree of automation can reduce manual intervention, avoid human errors, improve the stability and work efficiency of the production line, and thus shorten the overall printing time.

However, although the improvement of equipment and technology can improve production efficiency, sufficient drying time and fine process control are still required for tinplate sheet printing. This is because the surface of tinplate is relatively smooth during printing, and the ink adhesion is poor, and it must be precisely controlled to ensure the quality of the printing effect.

What factors will limit the specific time of tinplate sheet printing?

1. How long does it take to prepare before printing tinplate sheet?

Before officially starting printing, tinplate sheet needs to go through a series of preparations, which have a direct impact on the overall production cycle. For example, the surface of tinplate sheet needs to be treated to ensure that the ink can adhere firmly. These treatment steps usually include cleaning, oiling, preheating and other processes, the purpose of which is to remove impurities, oil stains and oxide layers on the surface to prepare for printing.

The time of this process may vary depending on the type of equipment in the production line, the complexity of the treatment process, and the quality of the tinplate sheet. Generally, the preparation takes 10 to 30 minutes, but if special surface treatments (such as anti-corrosion, anti-oxidation treatment, etc.) are required, the time may be longer.

2. How is the drying time after printing calculated?

In the printing process of tinplate sheet, drying time is a very important link. Since the surface of tinplate sheet is relatively smooth and the ink evaporates slowly, proper heating and drying are required to ensure the stability of the printing effect. The drying time is usually determined by the type of ink and the thickness of the printing.

In general, traditional inks require a longer drying time, which may take 20 to 30 minutes, while some fast-drying inks, especially UV inks, can be dried in a few seconds. Therefore, the type of ink used in the printing tinplate sheet process is a key factor affecting the drying time. For mass production, the choice of ink and the use of drying equipment can significantly improve production efficiency and shorten the overall printing time.

3. How does the time of each link affect the total production cycle?

In addition to the printing and drying process, the entire production process of printing tinplate sheet also includes the steps of post-inspection, trimming and packaging. Although the time of these links is relatively short, they will also have an impact on the total production cycle. Especially in terms of quality control, each link in the production process needs to be strictly tested and adjusted to ensure that each batch of tinplate sheet meets the quality standards.

For example, after printing tinplate sheet, color difference inspection, ink adhesion test, scratch inspection, etc. are required. If unqualified products appear, they need to be returned for rework, which will undoubtedly increase production time. In addition, packaging and transportation preparation also take a certain amount of time, especially when the order volume is large or special packaging is required, these links may require additional time to complete.

After printing, what is the processing time of tinplate sheet?

1. Does the printed tinplate sheet need secondary processing?

In the production process of some high-end products, the printed tinplate sheet may need secondary processing, such as stamping, welding, folding, etc. Stamping refers to stamping the tinplate sheet into the required packaging shape through a mold according to the design requirements. The time of this process depends on the complexity of the molding process and the degree of automation of the production line.

For simple shapes, the stamping time is relatively short, but for complex shapes, especially for packaging that requires precise control, the molding time will increase accordingly. After stamping, the tinplate sheet may also need to be heat treated, surface treated, etc., and the time of these steps will also lengthen the overall production cycle.

2. Do all tinplate sheets undergo secondary processing?

Not all tinplate sheets need to be processed secondary after printing. A simple printing and packaging production line may only need to print and simply fold the tinplate sheet, and then go directly to the packaging link. For some high-end customized products, more processing techniques may be required, including hot pressing, cold pressing, local coating, surface treatment, etc. Different processing steps and technical requirements will affect the time.

Dekai Metal Packaging – A One-Stop Shop for Packaging Solutions

Foshan Dekai Metal Packaging Co., Ltd. offers a full range of metal packaging products to suit your needs, including tinplates, aerosol cans, and top-quality printing services. As a leading manufacturer and supplier, we offer customized packaging solutions, bulk ordering options, and competitive prices. Get in touch for quotes, inquire about our ongoing promotions, and enjoy the best deals on high-quality metal packaging.