In the field of packaging, how to effectively recycle and reuse packaging materials has become a topic of common concern for many industries and consumers. As a common metal packaging material, tinplate sheet is widely used in many industries such as food, cosmetics, and beverages, but many consumers do not know enough about its recycling potential and practical operations.

This article will explore whether tinplate packaging can can be recycled and reused from multiple perspectives, and analyze the challenges and advantages in its recycling process.

Composition and recycling value of tinplate packaging can

1. How is tinplate can made?

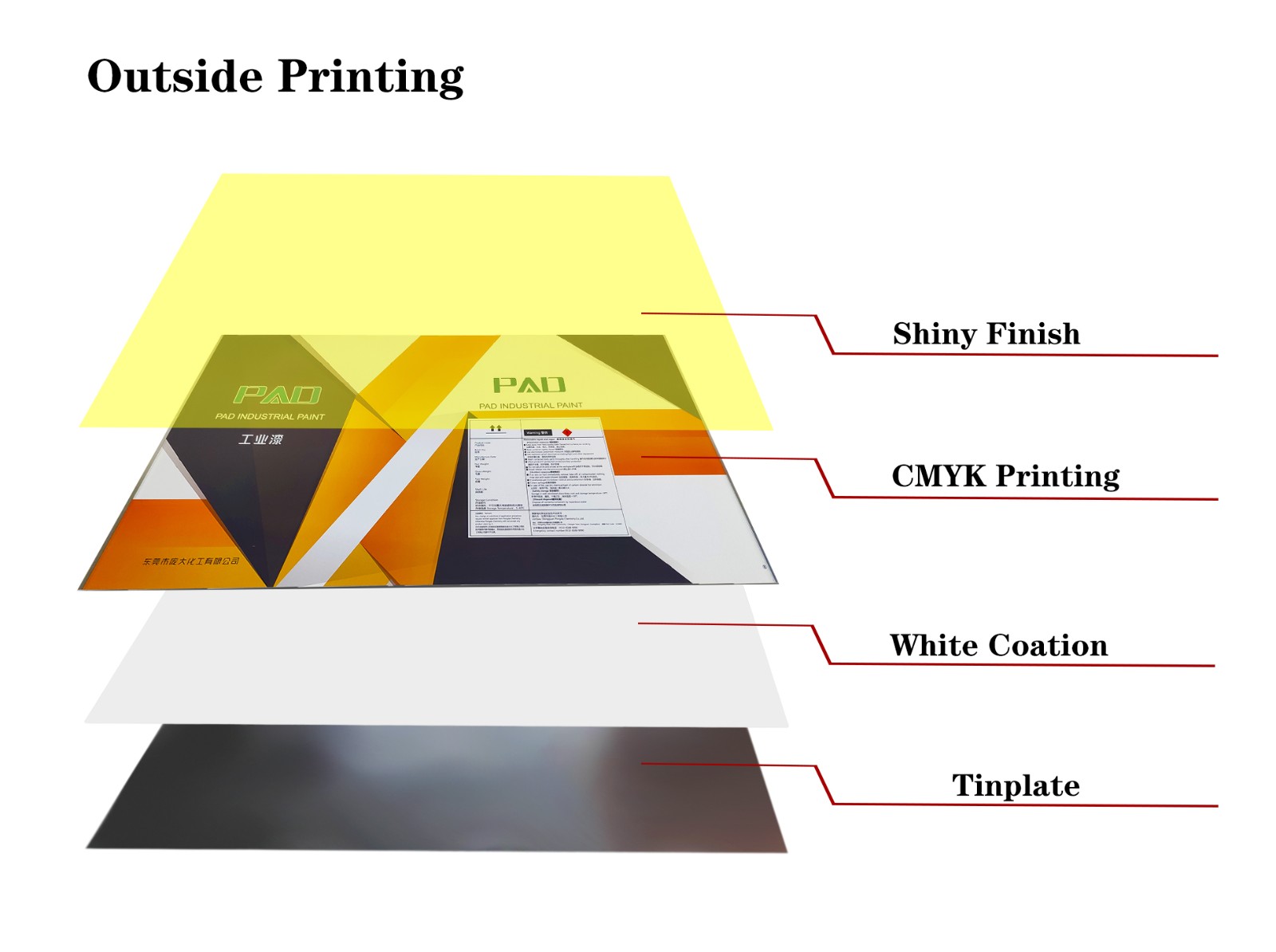

Tinplate sheet is a metal sheet made of steel plate and tin alloy through tin plating process, which is usually used to make various packaging cans. It consists of iron-based materials and tin plating layer, which is a key part to prevent metal rust. Due to the excellent corrosion resistance of tin, tinplate sheet has high durability and certain plasticity, and can be used to produce packaging cans of different shapes.

The appearance of tinplate can is usually painted or printed to form a highly recognizable and artistic packaging. It has good sealing properties and can effectively protect the quality of the product in the can, especially in the case of long-term storage, to avoid oxidation, moisture, deterioration and other problems of food or other products. Therefore, tinplate can is widely used to package high-end food, beverages, cosmetics, etc., and occupies a certain share in the market.

2. How much is the value of recycling tinplate sheet?

From the perspective of recycling, tinplate sheet has a high reuse value. Its iron-based material can be melted and reprocessed, and the tin layer can also be effectively recycled. Compared with other metal materials, tinplate sheet has higher economic and environmental benefits in the recycling process. The reprocessed tinplate sheet can be used to make new packaging, home appliances, auto parts, etc., thereby reducing dependence on new resources, reducing energy consumption, and reducing waste generation.

However, the details and processing procedures involved in the recycling process also require fine operation and management to avoid waste of resources. The recycled tinplate sheet must be cleaned, decontaminated, and ink removed to ensure that its quality meets the reuse standards.

Why can tinplate packaging can be recycled?

1. Is the recyclability of tinplate sheet better than other packaging materials?

Compared with plastic packaging materials, tinplate sheet has a higher recycling value. Plastic packaging materials usually need to go through more complicated sorting and processing procedures, and the quality after recycling is low. Tinplate sheet itself is a metal material, which does not require too much sorting during recycling and can be directly put into the furnace for reprocessing. Through remelting, tinplate sheet can be restored to raw materials and reused, avoiding waste of resources.

In addition, tinplate sheet itself is composed of two metals, iron and tin. Among them, tin is an important alloy component, and its recycling value is relatively high. In the recycling process of tin, after smelting and purification, it can be reused as a raw material for manufacturing other products, which greatly improves the economic benefits of recycling.

2. How environmentally friendly is tinplate packaging can?

Tinplate packaging can is not only recyclable, but also has good environmental protection. First of all, the recycling of tinplate packaging can can greatly reduce environmental pollution. Compared with plastic, paper and other packaging materials, metal materials have a higher recycling rate, and can be reused many times after recycling, and will not reduce performance due to repeated recycling. Secondly, the production and recycling process of tinplate packaging can is relatively environmentally friendly. Compared with the production process of plastic packaging, the production process of tinplate packaging can does not produce too much harmful gas or chemical waste, and due to the high recycling rate, it has less negative impact on the environment.

The recycling of tinplate sheet is not only beneficial to the environment, but also helps to save natural resources. For example, by recycling tinplate sheet, we can reduce the demand for mining of iron ore and tin ore, thereby reducing the excessive consumption of natural resources. The recycling of this material is in line with the concept of green and sustainable development.

Can tinplate packaging can be successfully recycled? Difficulties in the recycling process

1. Why is the recycling process of tinplate packaging can complicated?

Although tinplate sheet is a highly recyclable material, there are still certain difficulties in the actual recycling process. First, the surface of tinplate packaging can is usually printed and coated, and these coatings may affect the recycling quality of the metal. In particular, the composition of the printing ink and the adhesion of the coating may make the recycling process more complicated, requiring strict cleaning and removal of the metal surface.

Secondly, secondary pollution problems are often encountered during the actual use of tinplate can. For example, if a product containing grease or acidic substances has been stored in the can, it may interfere with the recycling process and cause unstable metal quality after recycling. Therefore, although tinplate can itself has a high recycling value, its recycling process still needs further technical support and management to ensure recycling efficiency and metal quality.

2. Can the recycled tinplate can be used for food packaging?

Whether the recycled tinplate can can continue to be used for food packaging is also a question that needs to be considered. Heat treatment, cleaning and other links in the recycling process will affect the surface quality of the metal. If it is not strictly tested and treated, the recycled tinplate sheet may not meet food safety requirements. Therefore, recycled tinplate sheet is often used in the manufacture of industrial products, such as home appliances, auto parts, etc., while its application in the field of food packaging is subject to certain restrictions.

In order to ensure that the recycled tinplate packaging can meet food grade requirements, the recycling plant needs to comply with strict hygiene standards and conduct comprehensive testing and disinfection of the recycled materials. In addition, high-quality coatings and inks are also required to ensure that the reused products will not pose a threat to food safety.

How to improve the recycling rate of tinplate sheet?

1. How to improve the recycling technology of tinplate sheet?

To improve the recycling rate and reuse level of tinplate packaging can, we first need to rely on more advanced recycling technology. At present, with the continuous development of recycling equipment, more and more efficient recycling technologies have emerged. For example, the use of high-temperature smelting technology can effectively remove the coating and impurities on the metal surface and improve the purity and quality of the recycled metal. In addition, the new magnetic separation technology can also effectively separate iron and tin, further improving the recycling efficiency.

In the recycling process, different treatment methods should be adopted for different types of packaging materials. For example, for tinplate cans with a large amount of coating, the coating can be removed by chemical treatment or heat treatment to reduce the pollution of recycled metals.

2. Strengthen consumers' recycling awareness

In addition to technical innovation, improving the recycling rate of tinplate sheet also depends on the active participation of consumers. After using tinplate packaging can, consumers should actively participate in the recycling action and send the discarded packaging cans to professional recycling sites in accordance with local recycling regulations. By strengthening consumers' environmental awareness, more tinplate packaging cans can be recycled and resource waste can be reduced.

Dekai – The Trusted Manufacturer of High-Quality Metal Packaging

Foshan Dekai Metal Packaging Co., Ltd. is an industry leader in the production of metal packaging products. We specialize in aerosol cans, tinplates, and custom printing, offering affordable prices and exceptional quality. Our factory is equipped with the latest automation technology to ensure high production capacity and quick delivery. Whether you need bulk quantities or customized solutions, we have the right products to meet your needs. Get in touch for purchasing inquiries and promotions.