07-01/2025

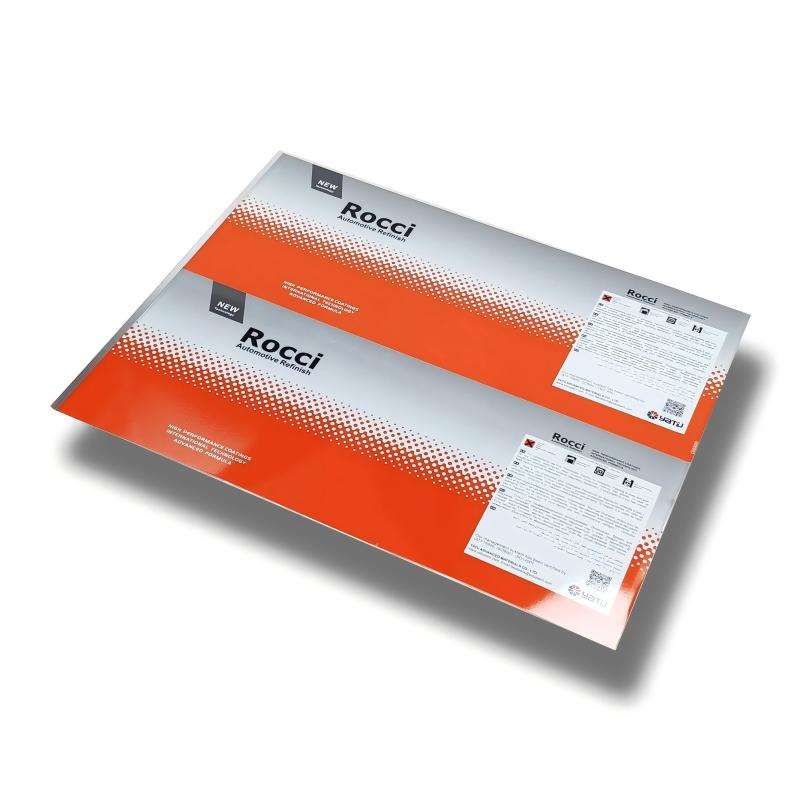

The amount of tin used in a standard tinplate can depends on its volume and the thickness of the coating. Typically, about 1 to 2 grams of tin are required per square meter of tinplate, which means that an ordinary food can does not require much tin, but its role is irreplaceable.