Tinplate cans are widely used in various packaging fields, especially in the food and beverage industry, due to their good corrosion resistance, strength and processing characteristics. However, during use, the corrosion resistance of tinplate cans faces multiple tests from the external environment. In order to ensure the stability of tinplate cans and the safety of the contents during long-term use, the selection of anti-corrosion coatings is particularly important. Suitable anti-corrosion coatings can not only effectively prevent oxidation and corrosion of the metal substrate, but also improve the printing effect and increase the beauty and durability of the packaging.

This article will discuss in detail how to choose anti-corrosion coatings for printing tinplate cans, focusing on the selection criteria, common coating types and their advantages and disadvantages, and provide some key factors to pay attention to when choosing coatings.

Why is anti-corrosion coating so important in the manufacture of tinplate cans?

Why do tinplate cans need anti-corrosion coatings?

Tinplate, usually refers to a steel plate coated with a tin layer, which has good corrosion resistance, but this protective layer is not always effective. As the use time increases, the tin layer may be damaged by friction, scratches or chemical reactions, exposing the metal matrix and increasing the risk of corrosion. Especially in humid, acidic or alkaline environments, uncoated tinplate is prone to oxidation, causing rust, corrosion and even leaks. In order to ensure the protective performance of tinplate cans, anti-corrosion coatings have become an indispensable part.

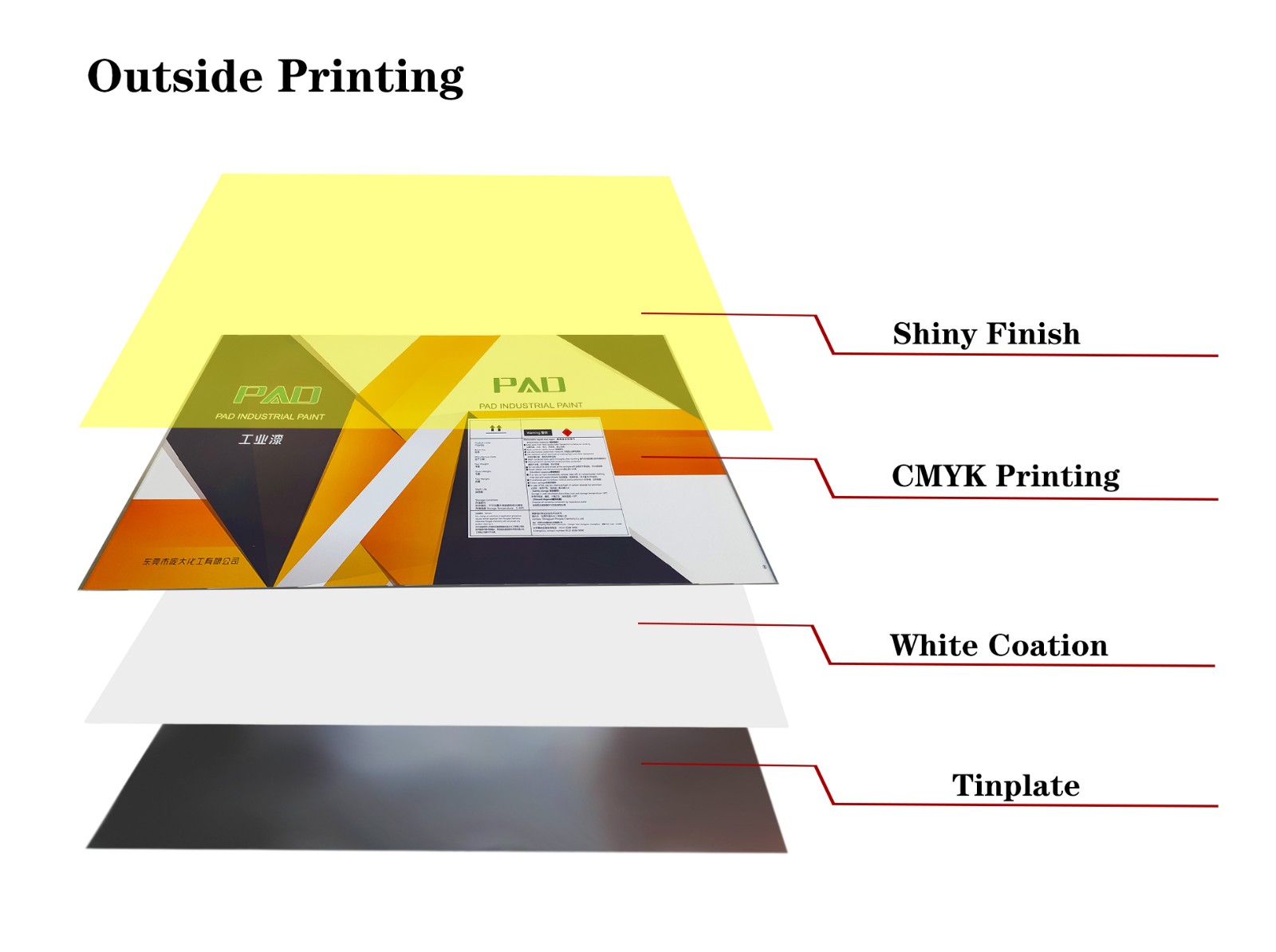

In addition, anti-corrosion coatings can also improve the printing effect of tinplate cans, ensure the appearance quality of packaging cans, and avoid stains caused by corrosion or oxidation that affect the product image. Therefore, choosing a suitable anti-corrosion coating can not only improve the durability of tinplate cans, but also ensure the long-term quality of the product.

The impact of anti-corrosion coatings on the performance of tinplate cans?

The quality of anti-corrosion coatings directly affects the durability of tinplate cans during use, especially its ability to protect different contents such as food, beverages or chemicals. High-quality anti-corrosion coatings can effectively isolate harmful substances from the outside world from contacting the metal surface and delay the corrosion process. Different types of coatings have different protective effects, temperature resistance, and UV resistance, so when choosing, you need to make a careful selection based on the specific use environment and application requirements.

Printing tinplate cans: How to choose the right anti-corrosion coating?

What factors should be considered for printing tinplate cans?

When choosing an anti-corrosion coating for printing tinplate cans, you need to consider the following key factors:

● Corrosion resistance of the coating: The main function of printing tinplate cans is to prevent oxidation or corrosion of the tinplate cans. Therefore, the corrosion resistance of the coating is particularly critical. For different types of products (such as food, beverages, or chemicals), the required anti-corrosion properties may be different. In humid environments, the coating must have strong water and moisture resistance, while in acidic or alkaline environments, it must have chemical corrosion resistance.

● Temperature resistance of the coating: Many tinplate cans need to be used or stored under high or low temperature conditions. For example, food cans often need to be sterilized at high temperatures, and beverage cans may be exposed to extreme climate conditions. The temperature resistance of the anticorrosive coating must be able to withstand these extreme conditions without falling off, changing color or performance degradation.

● Non-toxicity and food safety of the coating: For tinplate cans for food packaging, the non-toxicity of the coating is crucial. If the chemical components in the coating migrate into the food or beverage in the can, it may have adverse effects on health. Therefore, food-grade coatings need to meet strict food safety standards to ensure that the coating does not contain harmful substances and can have good contact with the contents.

● Processability of the coating: During the manufacturing process of tinplate cans, the coating must have good processability. For example, the coating must be adapted to the printing process, be able to work stably under high temperature and high pressure, and not easy to fall off or be damaged. In addition, the surface smoothness, adhesion and adaptability of the coating to the printed pattern also directly affect the appearance and printing effect of the final packaging can.

● Environmental protection of the coating: With the increasingly stringent environmental regulations, environmental protection has become an important consideration in the selection of coatings. Many countries have strictly restricted harmful substances (such as organic solvents, heavy metals, etc.) in coatings. Therefore, choosing environmentally friendly coatings with low volatility and low content of harmful substances is an inevitable trend in the manufacture of modern tinplate cans.

What types of anti-corrosion coatings can be used for printing tinplate cans?

There are many types of anti-corrosion coatings for printing tinplate cans on the market. Common types include epoxy resin coatings, polyester coatings, polyurethane coatings, and fluorinated coatings. Different types of coatings have certain differences in anti-corrosion performance, high temperature resistance, and chemical resistance. Below we will specifically analyze the characteristics of these common coatings:

Epoxy resin coatings

Epoxy resin coatings are a type of coating widely used for printing tinplate cans, especially for packaging cans that require high moisture and corrosion resistance. Epoxy resin coatings have strong adhesion and excellent waterproof properties, so they are widely used in food packaging and chemical packaging. In addition, epoxy resin coatings also have high heat resistance and chemical corrosion resistance, and are suitable for high temperature and chemical packaging.

Polyester coatings

Polyester coatings have good mechanical strength and weather resistance, and are especially suitable for tinplate cans for external printing. Its anti-corrosion performance is good, but compared with epoxy resin coating, polyester coating has slightly inferior chemical resistance. Therefore, polyester coating is mainly suitable for some milder environmental conditions.

Polyurethane coating

Polyurethane coating is often used in applications that need to withstand friction and high temperature due to its excellent wear resistance and high temperature resistance. Polyurethane coating is suitable for packaging cans in industries such as food and cosmetics. It has strong adhesion and good UV resistance, but the price is relatively high.

Fluorinated coating

The anti-corrosion performance of fluorinated coating is extremely outstanding, especially when used in harsh environments, it has excellent chemical erosion resistance and temperature resistance. It is often used for packaging cans in some special fields, but due to its high cost, it is mainly used for products that require special protection.

Printing tinplate cans: How to test the performance of anti-corrosion coatings?

How to evaluate the corrosion resistance of coatings?

The corrosion resistance of coatings is an important consideration when selecting materials. The corrosion resistance of coatings can be evaluated by the following methods:

● Salt spray test: Salt spray test is a common method to evaluate the corrosion resistance of coatings. By simulating the salt spray in the sea breeze environment, the corrosion of the coating is observed over a certain period of time. The longer the coating resists salt spray, the stronger its corrosion resistance is.

● Wet heat test: Place the sample after printing tinplate cans in a high humidity and high temperature environment, and evaluate its wet heat resistance by observing whether bubbles, shedding or discoloration appear on its surface.

Printing tinplate cans: How to detect the adhesion of the coating?

The adhesion of the coating is directly related to its durability and protective effect. Common adhesion test methods include:

● Scratch method: Make a scratch on the surface of the product after printing tinplate cans, and evaluate its adhesion by observing whether the coating peels off or cracks.

● Tensile test: Test the adhesion of the coating by applying tensile force, especially under extreme temperature and humidity conditions.

Foshan Dekai Metal Packaging Co., Ltd. is a leader in the metal packaging industry, offering printing tinplate cans, aerosol cans, and custom packaging designs. Based in Foshan, China, our factory is equipped with advanced FUJI UV printing lines and automated systems. We cater to wholesale buyers with competitive prices, bulk purchasing options, and reliable supply. As an ISO9001-certified manufacturer, we are committed to delivering exceptional quality and value. Contact us today for fast quotes and promotional offers.