Food packaging plays a vital role in the modern food industry, not only to protect the safety and freshness of food, but also involves brand display, extended shelf life and consumer experience. Among the many packaging materials, tinplate is widely used in the field of food packaging due to its excellent corrosion resistance, durability and environmental protection performance, and has become an indispensable material.

Tinplate products are widely used in food packaging, not only limited to traditional canned foods, but also covering various types of packaging forms. This article will start from different categories of food packaging and analyze in detail the specific applications of tinplate products in these fields.

What are the tinplate products in food packaging?

Tinplate products in food packaging:

1. Tinplate packaging in canned food

● Canned food

● Canned soup and liquid food

● Canned high-acid food

2. Tinplate products in beverage packaging

● Metal beverage cans

● Tea cans and coffee cans

3. Tinplate products in candy and snack packaging

● Candy boxes

● Biscuit and cake cans

● Potato chip cans

4. Tinplate products in dairy and milk powder packaging

● Milk powder cans

● Dairy packaging cans

5. Tinplate packaging for condiments and oily foods

● Condiment cans

● Edible oil packaging cans

1. Tinplate packaging in canned food

Canned food

Canned food is one of the most classic and common applications of tinplate. Tinplate cans are not only suitable for preserving foods such as meat, fish, vegetables and fruits, but are also widely used in candy, dairy products and condiments. The anti-corrosion and durability of tinplate allow these canned foods to remain fresh for a long time, avoiding the influence of external air, moisture, light and microorganisms.

● Canned meat: Tinplate cans are widely used in the packaging of various meat products, such as beef, chicken, ham, etc. These foods often need to be sterilized at high temperatures. The heat resistance of tinplate can ensure that the cans will not deform or affect the quality of the food during the high-temperature sterilization process.

● Canned fish: For example, seafood cans such as canned tuna and canned sardines also use a lot of tinplate. The oil components contained in canned fish are easy to oxidize. The use of tinplate packaging can effectively prevent oxygen penetration and extend the shelf life of fish food.

● Canned fruits and vegetables: Tinplate cans can also maintain the taste and nutrition of fruits and vegetables. For example, common canned peaches, canned tomatoes, etc., can effectively prevent the acidic substances of fruits and vegetables from reacting with metals by using tinplate packaging, and maintain the safety and flavor of the products.

Canned soup and liquid food

In addition to solid food, tinplate is also commonly used to package soup and liquid food. This type of product requires higher sealing and anti-corrosion performance of the packaging, and tinplate can provide excellent sealing effect through high-quality sealing technology, preventing external air from entering the can and ensuring the shelf life of soup food. At the same time, the strength of tinplate can effectively withstand the pressure during transportation and storage to avoid liquid leakage.

Canned high-acid food

High-acid foods (such as tomato products, citrus fruits, etc.) have more stringent requirements on packaging materials because their acidic components may react with metals, resulting in a decrease in food quality. The surface of tinplate is coated with a layer of tin, which can effectively prevent acidic substances from contacting the steel substrate and avoid harmful chemical reactions. In addition, certain special coating treatments can further enhance tinplate's resistance to acidic substances and ensure the safety of highly acidic foods.

2. Tinplate products in beverage packaging

Metal beverage cans

Tinplate is also widely used in the production of beverage cans, especially in the packaging of liquid products such as carbonated beverages, juices, tea beverages and beer. The use of beverage cans can be traced back to the 19th century, and tinplate has been widely used in this form of packaging since then. Since beverage products often contain moisture and acidic substances, using tinplate as a packaging material can effectively prevent oxygen from entering, maintain the carbonated state of the beverage, and avoid chemical reactions between the beverage and the packaging.

● Carbonated beverage cans: Carbonated beverages need to maintain the state of bubbles for a long time. The sealing of tinplate can ensure that carbon dioxide will not escape easily, and its corrosion resistance ensures that the beverage is not affected by the packaging material.

● Beer cans: Beer also has high requirements for the sealing of packaging. Tinplate cans can avoid interference from external factors such as light and air, and maintain the freshness and taste of beer.

Tea cans and coffee cans

Although tea and coffee are not liquids, they have extremely high requirements for the sealing and light-proof properties of the packaging because they are easy to absorb moisture and are affected by light. Sealed cans made of tinplate can ensure that tea and coffee are not affected by air humidity during storage, maintaining their unique aroma and quality.

Tinplate tea cans are usually beautifully designed and have good sealing properties. They can effectively block outside air and moisture from entering the cans, extending the shelf life of tea. The same is true for coffee cans. Tinplate materials can not only maintain the flavor of coffee beans, but also have good moisture-proof effects.

3. Tinplate products in candy and snack packaging

Candy boxes

Candy packaging is one of the important application areas of tinplate products. Candy products require packaging that is not only moisture-proof and sealed, but also has a very important appearance design. Tinplate candy boxes are not only moisture-proof and insect-proof, but also can achieve exquisite appearance designs through printing, embossing and other processes to enhance the display effect of their products.

For example, various high-end chocolate and candy brands often use exquisite packaging boxes made of tinplate. These packaging can not only effectively protect the products from the influence of the external environment, but also have collection value. When consumers buy these candies, they often pay attention to the beauty and reusability of their packaging. The advantages of tinplate products in this regard are obvious.

Biscuit and pastry tins

Biscuit and pastry products are susceptible to moisture, resulting in a poor taste. Therefore, many biscuits, cookies and pastry products are packaged in tinplate cans. The sealing and moisture-proof properties of tinplate cans can ensure the crispness and taste of the food, keeping it fresh for a long time. At the same time, the durability and decorativeness of tinplate cans also make it a common choice in holiday gift box packaging, especially during the holidays, when consumers are more inclined to buy biscuit and pastry tins with decorative patterns.

Potato chip cans

As a crispy snack, potato chips also need to maintain their crisp taste in the packaging. Many potato chip brands use tinplate cans for packaging to ensure that the potato chips are not affected by external moisture and air and maintain their crisp state. In addition, the hardness of tinplate cans is enough to protect potato chips from being crushed during transportation, which is crucial to maintaining the integrity of snacks.

4. Tinplate products in dairy and milk powder packaging

Milk powder cans

As a highly perishable dairy product, milk powder has extremely high requirements for the safety and sealing of packaging materials. Tinplate milk powder cans are widely used in the packaging of various infant milk powders, adult milk powders and special nutritional products due to their excellent sealing performance and moisture-proof effect.

Milk powder cans made of tinplate can effectively prevent air, light and moisture from damaging milk powder, keeping the milk powder dry and fresh. At the same time, milk powder cans are usually equipped with sealing lids, which are convenient for consumers to take multiple times and can continue to keep the product fresh after each use.

Dairy packaging cans

In addition to milk powder, some dairy products, such as condensed milk, cream, etc., are also packaged in tinplate cans. Tinplate can ensure the hygiene and safety of these dairy products during the packaging process, and will not be affected during the high-temperature sterilization process, ensuring the quality and taste of dairy products after packaging.

5. Tinplate packaging of condiments and oily foods

Condiment cans

Many condiments, such as ketchup, mustard, chili sauce, etc., usually need to be packaged in tinplate cans. Condiments often contain acidic or alkaline substances, which are easy to react with other packaging materials. Tin coating of tinplate can effectively prevent these substances from corroding the packaging materials, ensuring the safety and flavor of condiments.

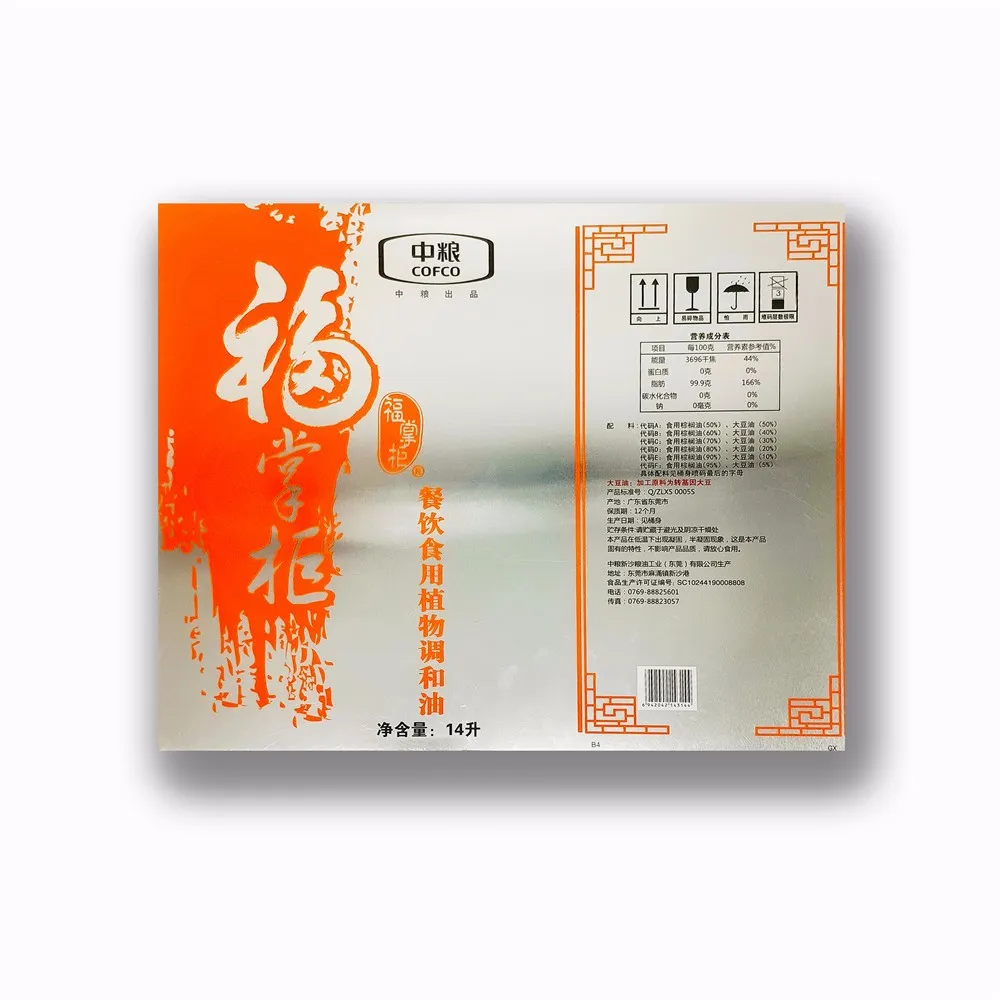

Edible oil packaging cans

Tinplate is also widely used in the packaging of edible oils, especially high-end edible oils such as olive oil and sesame oil. Edible oil products have extremely high requirements for the sealing and light-proof properties of packaging, because oils will oxidize when exposed to air or light for a long time, affecting the taste and nutritional content. The sealing and light-proof properties of tinplate cans can effectively prevent the oxidation of oils and extend the shelf life of edible oils.