04-01/2025

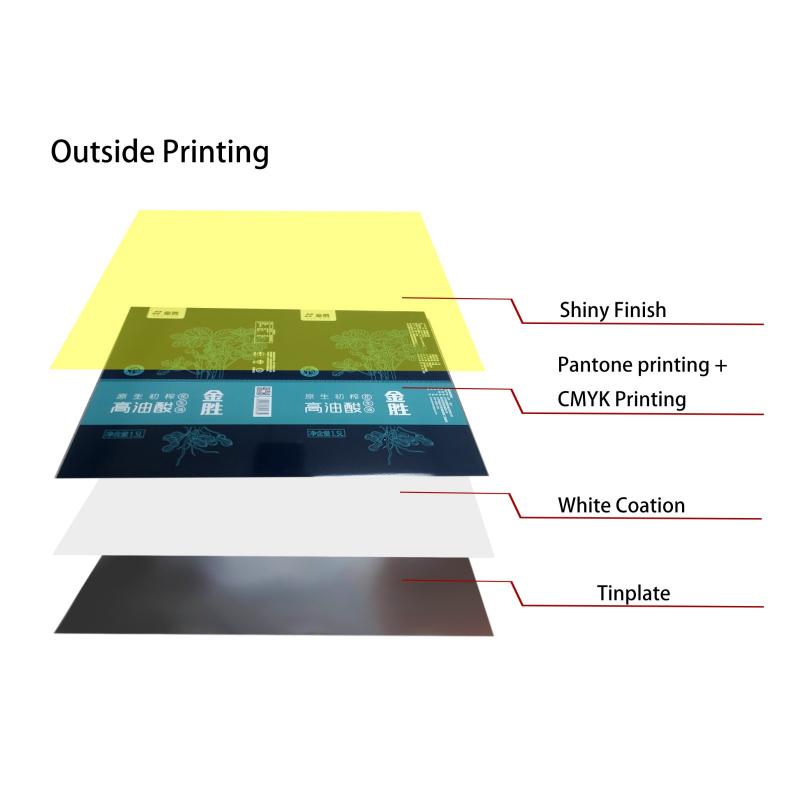

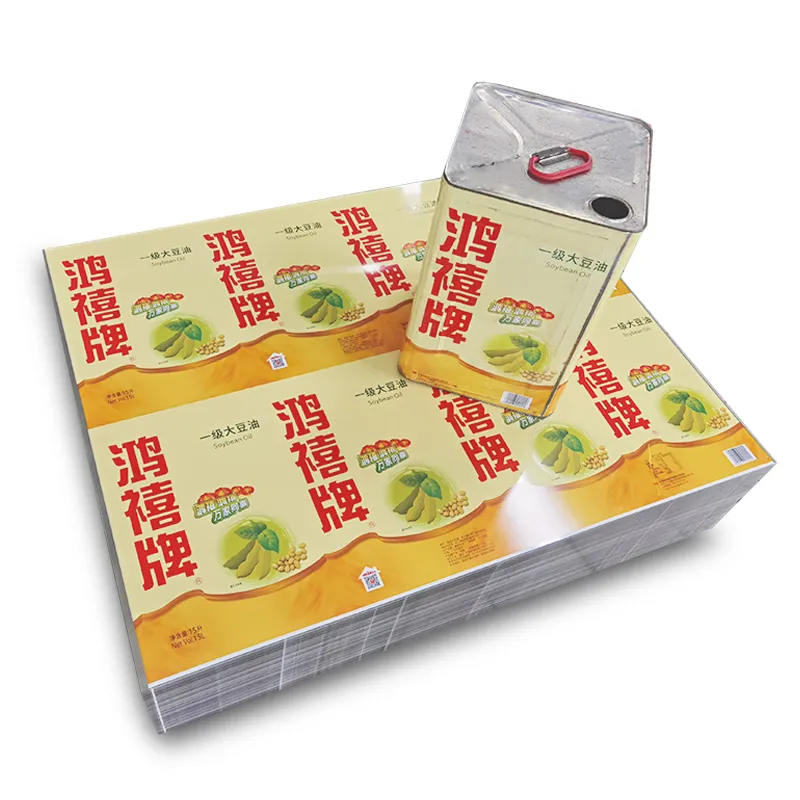

Tinplate steel performs well in corrosion resistance due to the protection of the tin coating. Especially in contact with food or liquids, the corrosion resistance of tinplate steel can effectively prevent the penetration of moisture and oxygen, and maintain the freshness of the contents of the can.