The wide application of tin plate cans in the field of food packaging has attracted the attention of many people. As a traditional and enduring packaging material, why can tin plate cans occupy a place in the fierce market competition? Why do food packaging, especially canned food and high-end gift packaging, always favor tin plate, a metal material?

This article will analyze tin plate cans from multiple angles, including physical properties, food safety, preservation effect, printing and decoration performance, to reveal the answer to this question.

Why do food packaging like to use tin plate cans?

As one of the choices for food packaging, tin plate cans have many advantages, one of the important reasons is the extension of product shelf life. Tin packaging can effectively block the intrusion of light, moisture and oxygen, thereby reducing the impact on product quality. Especially for perishable foods, such as jam, soy sauce, etc., the use of tin plate cans can extend their shelf life, maintain their freshness and flavor, and allow consumers to enjoy delicious food for a longer time.

Basic characteristics of tin plate and its compatibility with food packaging:

1. Strong corrosion resistance

2. Good sealing performance

3. High mechanical strength

4. Strong plasticity

Tin plate is a metal material made of tin-plated cold-rolled steel plate. Its core features include strong corrosion resistance, good sealing performance, high mechanical strength, and strong plasticity. These features are highly consistent with the needs of food packaging, making tin plate cans the only choice for many food manufacturers.

Strong corrosion resistance

One of the biggest features of tin plate is its excellent corrosion resistance. This is mainly due to the tin coating on its surface. Food packaging requires that the material can resist the erosion of oxygen and moisture for a long time to prevent the spoilage of food. The tin coating on the surface of tin plate can effectively isolate air and moisture, prevent metal oxidation and rust, and thus extend the shelf life of food. For canned food and products that are stored for a long time, corrosion resistance is particularly important, which is one of the reasons why tin plate cans can stand out.

Good sealing performance

One of the core requirements for canned food packaging is its sealing performance. Well-sealed packaging can prevent food from contacting with the outside air and moisture, delaying the oxidation and corruption of food. The strength and toughness of tin plate cans enable it to fit tightly to the can body and lid during the manufacturing process, forming an excellent sealing effect. This sealing is not only suitable for the packaging of ordinary food, but can even be sterilized under high temperature and high pressure conditions, such as high-temperature canned food.

High mechanical strength

Food packaging needs to withstand certain external force impacts during transportation and storage, such as stacking and handling. If the strength of the packaging material is not enough, the food is very likely to leak, break or deteriorate due to external extrusion. Tin plate has high mechanical strength and can withstand greater pressure without deformation, ensuring the safety of food during transportation and storage. This advantage is particularly prominent in situations where flexible packaging materials (such as plastic bags) cannot meet the requirements.

Strong plasticity

The plasticity of tin plate enables it to be processed into food packaging cans of various shapes and sizes to meet the packaging needs of different foods. Whether it is a traditional round can or a special-shaped can that has become popular in recent years, tin plate can meet design requirements through flexible processing technology. This allows tin plate packaging to adapt to the market positioning of different products and become a powerful assistant for food packaging designers.

Food safety of tin plate cans:

1. Use of food-grade materials

2. Adaptability to high-temperature sterilization

3. Light and gas penetration protection

Food safety is the primary consideration for food packaging, and tin plate cans have won the favor of the market with its excellent food safety. The presence of the tin layer allows tin plate cans to not undergo harmful chemical reactions when in contact with food, ensuring that the original taste and nutritional content of the food are not affected.

Use of food-grade materials

Tin plate has undergone strict food-grade certification to ensure that the materials on its surface will not react chemically with acidic and alkaline substances in food. Metal dissolution in food packaging is one of the most concerned issues for consumers, and tin plate cans are not easy to react with food due to the protection of the tin layer. This chemical stability ensures the safety of tin plate cans, especially for foods with strong acidity (such as fruits, juices, etc.), tin plate cans can still ensure that the food in the package is not contaminated.

Adaptability to high temperature sterilization

Many canned foods need to be sterilized at high temperatures to ensure long-term preservation of the food. This sterilization method places extremely high demands on the high temperature resistance of packaging materials. Tin plate cans can not only withstand high temperature treatment, but also do not produce harmful substances in high temperature environments, nor do they affect the quality of the food inside the package. Therefore, tin plate cans can meet the needs of high temperature sterilization and provide food manufacturers with a safer and more stable packaging option.

Anti-light and anti-gas penetration

The preservation of food does not only rely on physical isolation, but external factors such as light and oxygen can also accelerate the deterioration of food. Due to the inherent advantages of its metal material, tin plate cans can effectively isolate light and prevent the decomposition of nutrients in food such as vitamins and pigments. In addition, tin plate cans can also prevent oxygen penetration and prevent food from oxidizing and deteriorating.

Tin plate cans are ideal materials for extending the shelf life of food:

1. Prevent external contamination

2. Retain the nutritional components of food

3. Ensure the taste and flavor of food

For the food industry, how to effectively extend the shelf life of food has always been a core issue. The shelf life of food is directly related to the stability of the product during sales and storage. Tin plate cans have become an ideal packaging material for extending the shelf life of food due to their excellent protection and sealing properties.

Prevent external contamination

The sealing design of tin plate cans can effectively prevent external contaminants (such as dust, insects, etc.) from entering the packaging. This is especially important for foods with demanding storage conditions such as canned meat and fish. In addition, tin plate cans can also prevent the invasion of odors, ensuring that the taste and flavor of the food during storage will not be affected by the external environment.

Preserve the nutrients of food

The sealing of tin plate cans can not only effectively prevent the infiltration of oxygen and moisture, but also prevent the loss of moisture and nutrients inside the food. Many foods will undergo oxidation reactions after being exposed to air, resulting in the loss of nutrients. Tin plate cans can provide a closed environment for food to maintain the original nutrients of the food, especially canned food, which is treated at high temperature after packaging, and can maintain the freshness and nutritional value of the food for a long time.

Ensure the taste and flavor of food

When consumers buy food, in addition to paying attention to the nutritional value of food, the taste and flavor of food are also very important. Tin plate cans can effectively isolate air, light and moisture to prevent the taste of food from changing during storage. For example, tin plate cans can maintain the original aroma of foods such as tea, coffee, and spices, and prevent them from gradually losing their flavor during long-term storage.

Tin plate cans' strong decorative performance and market competitiveness:

1. Excellent printing effect

2. Diverse styling designs

3. A symbol of high-end products

Tin plate cans are not only a protective barrier for food, but also an important medium for food brand display and consumer attraction. Its surface can be printed and decorated with high-quality design, which gives tin plate cans a unique competitive advantage in the food packaging market.

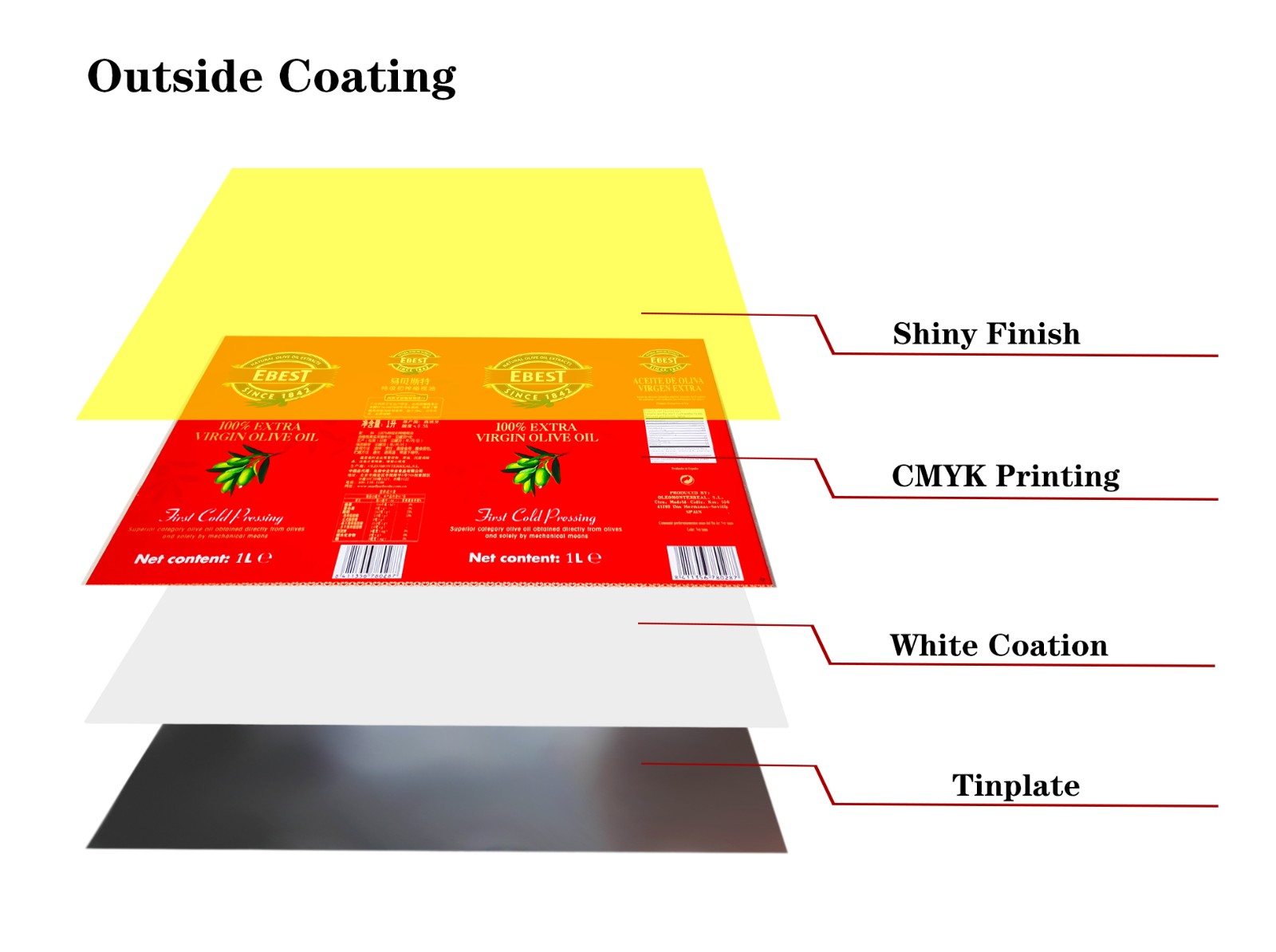

Excellent printing effect

The metal surface of tin plate cans can be printed with high quality, and the pattern is brightly colored and durable. Compared with other packaging materials, the printed pattern of tin plate cans is not easy to fade, and can maintain a beautiful appearance for a long time, attracting the attention of consumers. Especially in gift food packaging, tin plate cans are often designed very beautifully, becoming one of the added value of the product.

Diverse design

The strong plasticity of tin plate cans enables them to be processed into various shapes and sizes to meet the packaging needs of different products. Whether it is the traditional round cans or the popular special-shaped cans in recent years, tin plate can provide more design options for food packaging through flexible processing technology. This diversity not only increases the beauty of tin plate cans, but also gives the products more personalized elements.

Symbol of high-end products

In the minds of consumers, metal packaging materials such as tin plate cans are often regarded as symbols of high-end products. Its durable and metallic appearance adds a sense of luxury to the product. Especially when used for high-end food or gift packaging, tin plate cans can effectively enhance the overall image of the product and enhance consumers' desire to buy.

Environmental protection and sustainability of tin plate cans:

1. High recycling rate of tin plate cans

2. Potential for reuse

The environmental protection of tin plate cans plays an important role in food packaging. Metal materials are naturally recyclable, and the use of tin plate cans not only meets food safety and market demand, but also responds to global concerns about environmental protection and sustainable development to a certain extent.

High recycling rate of tin plate cans

Tin plate cans are 100% recyclable, and the quality and performance of the metal will not be reduced during the recycling process. Recycled tin plates can be used to produce new metal materials, thereby reducing dependence on natural resources. This feature makes tin plate cans an environmentally conscious food packaging choice.

Potential for reuse

In addition to being recyclable, tin plate cans are often designed to be highly durable and beautiful, so consumers often reuse them as storage cans, decorations, etc. after use. In this way, the service life of tin plate cans is greatly extended, reducing the waste of disposable packaging materials.