In our daily lives, tin plate cans are widely used in packaging for food, beverages, cosmetics, and many people think that these metal cans are particularly strong and reliable. Careful consumers may find that the surface of tin plate cans is covered with a layer of shiny metal, which is actually "tin".

So why are tin plate cans tin-plated? What is the role of the tin layer? What kind of protective effect does it have in practical applications? With these questions, this article will delve into the necessity of tin plate cans tin plating and the scientific principles behind it.

What are tin plate cans? Why choose tin as a protective layer?

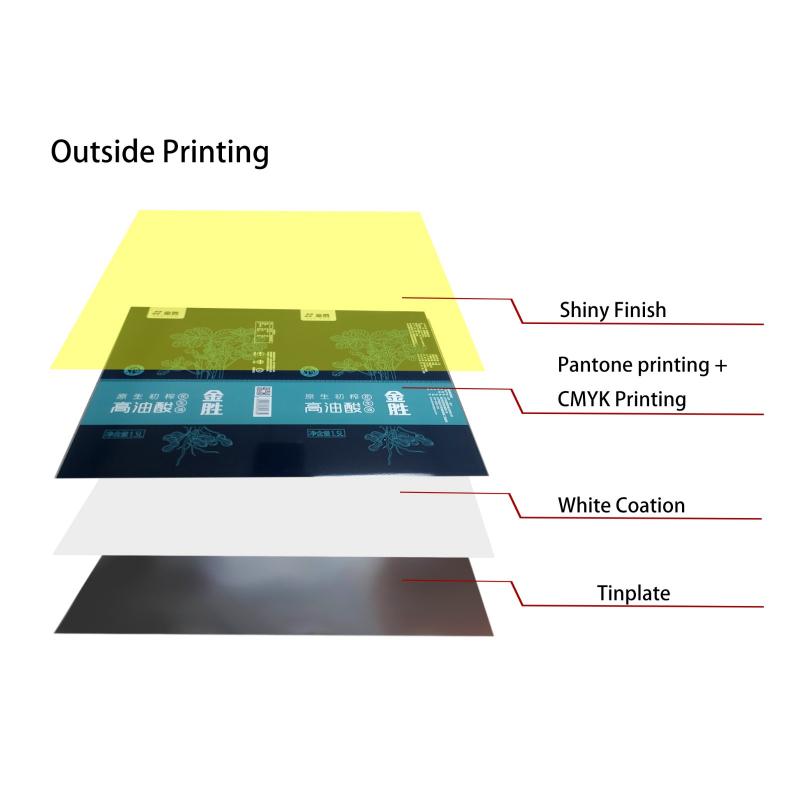

What is the basic structure of tin plate cans?

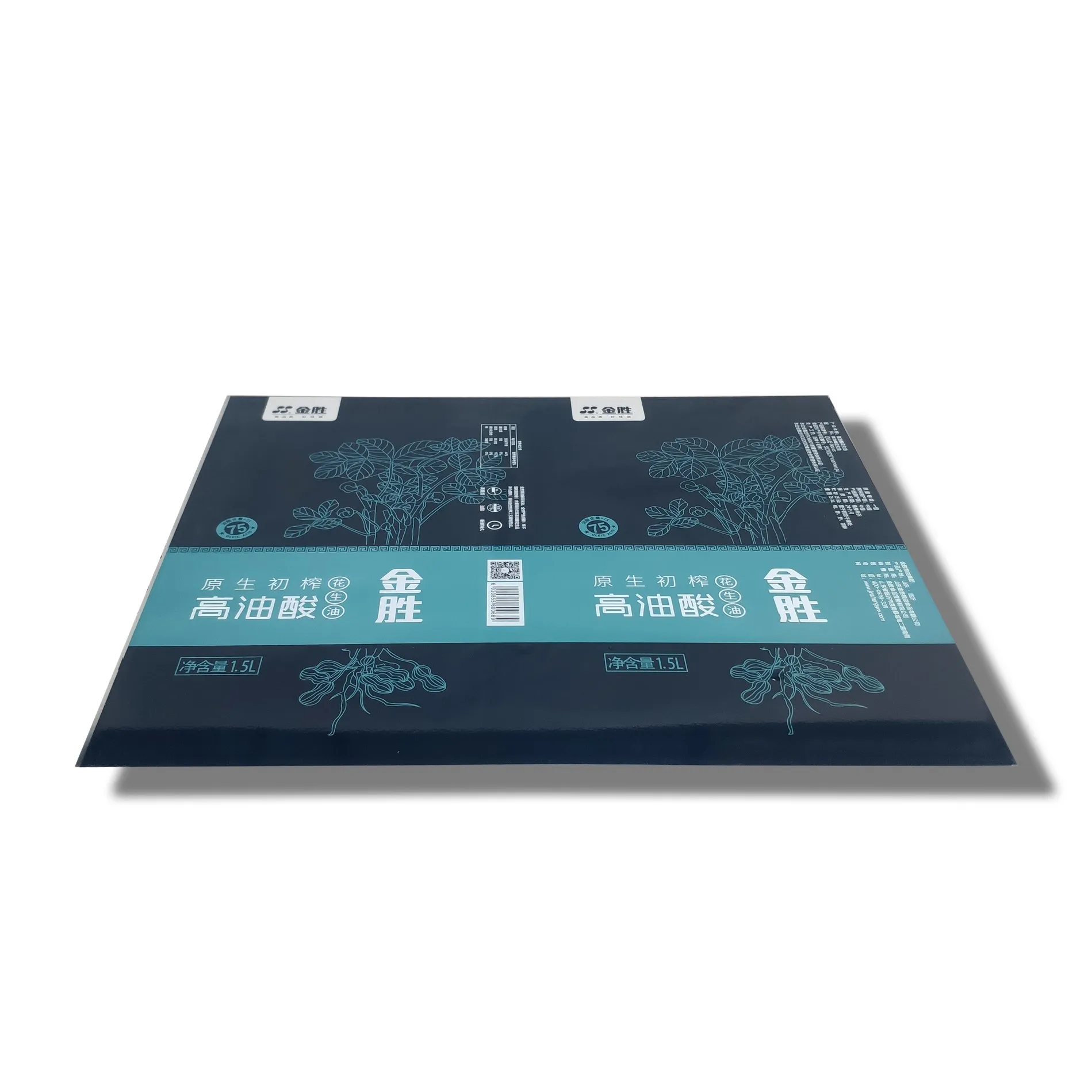

Tin plate cans are essentially a type of metal can made of low-carbon steel. Low-carbon steel has good mechanical strength and can withstand the pressure of various links such as transportation, stacking, and storage. However, because the iron element in low-carbon steel easily reacts with oxygen and moisture in the air, it produces oxidation reactions (rust), which causes corrosion and damage to tin plate cans, affecting the quality of the contents.

In order to extend the service life of the iron can and ensure the safety of the contents, tin plate cans are usually plated with a layer of metal tin on the surface of low carbon steel during the manufacturing process. This thin layer of tin can not only effectively prevent the oxidation and corrosion of iron, but also reduce the impact of metal on the packaging, thereby ensuring that the quality of the contents in the can is not destroyed.

Why choose tin instead of other metals?

The chemical properties of tin are relatively stable, and it has strong resistance to chemicals such as acids, alkalis, and salts, which means that it is not easy to react with other substances. Unlike iron, tin is not easy to rust, and it has high safety in food contact and does not produce substances harmful to the human body. In contrast, although other metals such as aluminum and zinc also have certain corrosion resistance, they cannot completely avoid oxidation, and are not as safe and chemically stable as tin, so tin has become the preferred material for tin plate cans coating.

What role does the tin coating play in corrosion prevention?

How does the tin layer prevent tin plate cans from rusting?

The tin coating of tin plate cans can prevent tin plate cans from rusting, which is mainly due to the chemical inertness of tin. The tin layer forms a protective barrier that blocks direct contact between air, moisture and corrosive substances and the iron. Even in a humid or acidic environment, the tin layer can effectively protect the tin plate cans and prevent the iron from oxidizing with oxygen and moisture in the air. In this way, the tin plate cans can maintain their structural integrity for a long time and avoid problems such as tin plate cans leakage and food contamination caused by corrosion.

How does the thickness of the tin layer affect the protective effect?

The thickness of the tin layer directly affects its protective effect. Generally speaking, the thicker the tin layer, the more effective the protection of the iron. However, due to the high cost of tin, too thick a coating will increase production costs. Therefore, in actual production, the thickness of the tin layer of tin plate cans is usually controlled within a certain range to achieve a balance between protective effect and production cost.

In addition, the uniformity of the tin layer is also an important consideration. A uniform tin layer ensures that all parts of the surface of the tin plate cans are protected to the same extent, avoiding local corrosion of certain weak points due to insufficient protection. In order to achieve uniform distribution of the tin layer, advanced electroplating technology needs to be used in the production process to ensure that tin is evenly deposited on the surface of tin plate cans, so as to achieve the ideal protective effect.

What are the important roles of tin plating for food packaging?

How to prevent food from being contaminated by metal?

Food in packaging, especially acidic foods (such as canned fruit, tomato sauce, etc.), easily react with metals, thus causing "metal migration". Metal migration not only changes the taste and color of food, but may also affect the safety of food. As the surface coating of tin plate cans, the tin layer can effectively block the direct contact between food and iron materials, and prevent metal ions from migrating into food, thereby ensuring the taste and quality of food.

In contrast, without the protection of the tin layer, acidic foods may react chemically with iron to generate metal compounds and be absorbed by food, which poses a potential risk to food safety. The protection of the tin layer forms a barrier between food and iron materials, eliminating the possibility of migration of harmful substances and greatly improving the safety of food packaging.

How does the tin plating layer help the shelf life of food?

The tin coating not only protects the iron from corrosion, but also indirectly extends the shelf life of the food. The sealing of tin plate cans combined with the protection of the tin layer can reduce the damage of oxygen and moisture to the food, prevent the growth of microorganisms and oxidation. In this way, the food can remain fresh for a long time and delay the process of spoilage.

Especially in the preservation of canned food, the role of the tin layer is particularly significant. Canned food usually requires high-temperature sterilization, and high temperature will accelerate certain chemical reactions. Without the protection of the tin layer, tin plate cans are prone to metal migration and oxidation reactions at high temperatures, affecting the taste and nutritional content of the food. Therefore, the tin coating has become an indispensable protective barrier when packaging food in tin plate cans.

How does the tin coating improve the durability of tin plate cans?

Can the tin coating prevent mechanical damage?

Although the tin layer itself is not particularly strong, it can provide certain mechanical protection, especially during transportation and storage. The presence of the tin layer can slow down the impact of some minor friction and collisions on the tin plate cans, and reduce the possibility of scratches and wear on the surface of the tin plate cans. Even if part of the tin layer is scraped off, the coating of the tin plate cans can still play a certain protective role, thereby improving the durability of the tin plate cans to a certain extent.

How does the tin layer perform in daily storage?

In daily storage, tin plate cans are usually kept at room temperature, but some storage places may have high humidity. The protective properties of the tin layer enable tin plate cans to maintain good anti-corrosion properties even in high humidity environments and are not prone to rust. Compared with untinned iron cans, tin plate cans have stronger rust resistance, so they are particularly suitable for some long-term storage applications.

How to ensure the quality of the tin layer?

What are the key processes in the tinning process?

The tinning process is a sophisticated process that usually includes cleaning, pickling, electroplating, washing and drying. In the electroplating stage, a certain current is applied to the tin plate cans to make the tin ions evenly attached to the surface of the iron material. The current, voltage and time control of this process are crucial because these factors directly affect the thickness and uniformity of the tin layer.

In addition, the pickling step is also to ensure that the surface of the tin plate cans is free of oil and impurities so that the tin layer can better adhere to the iron material. Only when every step is accurate and correct can a tin-plated layer that meets the quality standards be obtained, thereby improving the overall quality of the tin plate cans.

How to detect the quality of the tin-plated layer?

The quality inspection of the tin-plated layer includes thickness measurement, uniformity inspection, and corrosion resistance test. Among them, thickness measurement can be carried out by precision instruments to ensure that the tin layer is within the set range; uniformity inspection is to detect the distribution of the tin layer in various parts of the tin plate cans to avoid weak points.

The corrosion resistance test simulates the corrosive environment to observe whether the tin layer can effectively resist the erosion of chemical substances. After strict testing, qualified tin-plated tin plate cans can be put on the market to ensure that consumers get the best protection when using them.

Does the use of the tin layer affect the environmental protection of tin plate cans?

Can tin-plated tin plate cans be recycled?

Tin-plated tin plate cans have good recyclability, which is also one of its environmental protection characteristics. Although there is a layer of tin on the surface of tin plate cans, the separation technology of tin and iron is quite mature in the recycling process. After recycling, tin and iron can be processed and reused separately to reduce the consumption of natural resources.

Is the tinning process environmentally friendly?

Certain chemical reagents are used in the traditional tinning process, so the environmental protection requirements are getting higher and higher. Modern production processes have gradually reduced the pollution to the environment during the tinning process. By improving waste liquid treatment technology and clean production processes, the impact of tinned tin plate cans production on the environment has been significantly reduced.