Tin plate cans, as the preferred material widely used in the packaging of food, cosmetics and daily commodities, the printing process on its surface is directly related to the brand image and the market competitiveness of the product. Especially in brand packaging design, the LOGO is an important identification symbol of the corporate brand, and its clarity and durability directly affect consumers' brand recognition and purchasing decisions.

So, how long can the LOGO printed on tin plate cans remain bright? Is it easy to fade? How much impact does the choice of tin plate cans printing process have on the durability of the LOGO? This article will analyze these issues in depth to provide consumers and manufacturers with clearer answers.

Why does the LOGO on tin plate cans fade?

What are the main reasons for the LOGO fading?

The fading problem of the LOGO on tin plate cans is the result of the combined action of multiple factors. First, whether the adhesion between the printed pigment and the surface of the tin plate cans is strong enough is the key factor in determining whether the LOGO can remain bright for a long time. Secondly, the influence of the external environment, such as sunlight, humidity in the air, oxygen, etc., will also accelerate the fading process of the LOGO.

Specifically, the reasons for the fading of the LOGO on tin plate cans can be mainly attributed to the following:

● Ultraviolet (UV) irradiation: Long-term exposure to sunlight, UV rays will destroy the chemical structure of the ink molecules, causing the pigment to gradually fade. This is why many packaging materials, especially those used outdoors, often need to have an anti-UV coating.

● Friction and collision: The surface of tin plate cans may encounter friction and collision during transportation, stacking, and use. These physical damages will directly cause the printed LOGO to fade or scratch.

● Chemical reaction: Certain chemical components (such as strong acids, strong alkalis, or certain detergents) may react with the printed ink, thereby destroying the stability of the ink and causing the color to fade or peel off.

● High temperature and humidity: High temperature and humidity may cause the solvent in the ink to evaporate, thereby affecting the adhesion of the ink and causing it to fade.

Therefore, whether the LOGO printed on tin plate cans can last depends on many factors, including the type of ink selected, the storage and transportation conditions of the packaging, etc.

Does the LOGO fade at the same speed in different environments?

We often see that different types of packaging materials show different durability under different environmental conditions. Does the LOGO of tin plate cans fade at different speeds under the influence of environmental factors such as sunlight, humidity changes, and temperature fluctuations?

In fact, the storage environment of the packaged product has a crucial impact on the fading speed of the LOGO. The following factors may accelerate the fading of the LOGO on tin plate cans:

● Direct sunlight: Exposure to sunlight, especially strong ultraviolet rays, will accelerate the fading of the LOGO. Ultraviolet rays will destroy the dye molecules in the ink, causing the pigment to decompose, resulting in color fading. To delay fading, many manufacturers will design anti-UV coatings for tin plate cans.

● Temperature changes: Alternating high and low temperatures may cause the adhesion of the ink between the surface and the tin plate cans to weaken, causing the pigment to fall off or fade. In addition, when the temperature is too high, solvent evaporation may also reduce the printing quality.

● Humidity: In a high humidity environment, the surface of the tin plate cans may be eroded by water vapor, causing the ink to dissolve or peel off, and then fade.

Therefore, when storing and transporting tinplate packaging cans, suitable environmental conditions (such as low temperature, dryness, avoiding direct sunlight, etc.) will greatly slow down the fading speed of the LOGO.

How to prevent fading of tin plate cans LOGO?

Can choosing the right ink effectively extend the service life of tin plate cans LOGO?

Whether the LOGO on tin plate cans is easy to fade is closely related to the type of ink used. The type, quality and adhesion of the ink to the tin plate surface will affect the durability of the LOGO.

● UV ink: Ultraviolet curing ink (UV ink) has gradually become the mainstream choice in tin plate cans packaging. UV ink uses ultraviolet light source to cure, so that it dries quickly after printing, and can improve the adhesion of the ink. UV ink not only has excellent UV resistance, but also effectively prevents fading and discoloration problems.

● Solvent-based ink: Traditional solvent-based ink is more common and has good color expression and adhesion. However, in the long-term exposure environment of tin plate cans, this ink may be affected by ultraviolet rays and temperature changes, and fade.

● Water-based ink: Water-based ink is more environmentally friendly than solvent-based ink. Although water-based ink has better fading resistance, it may still face fading problems in certain high temperature and high humidity environments.

Therefore, choosing the right ink is crucial to extending the service life of tin plate cans LOGO. Especially in cosmetics and food packaging that have high requirements for durability, UV ink is often selected as the preferred material.

Do tin plate cans need an additional protective layer to extend the service life of the LOGO?

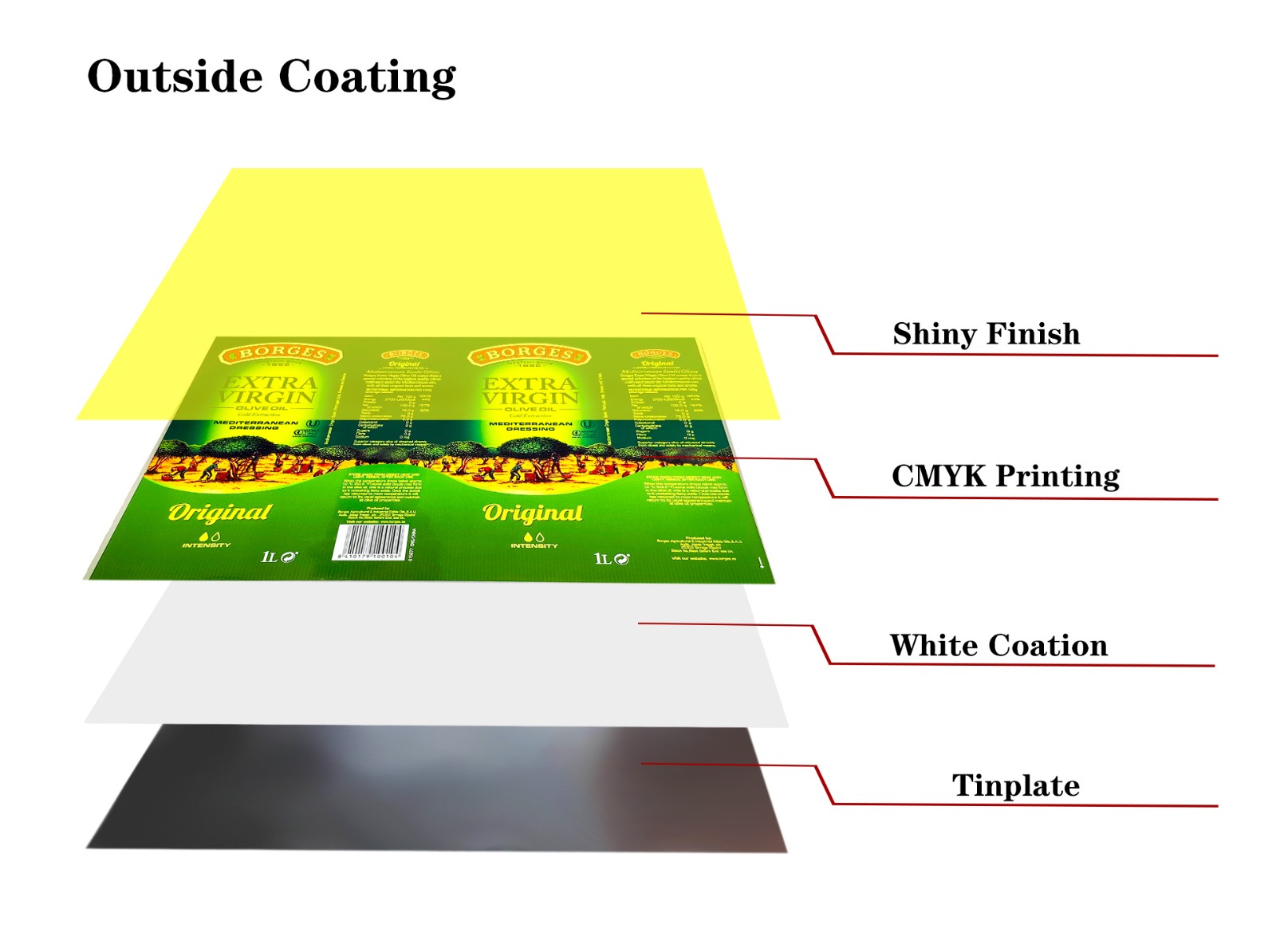

In addition to choosing the right ink, an additional protective layer can also effectively improve the durability of the LOGO. Especially for those tin plate cans that are exposed to the outside for a long time (such as cosmetics, beverage cans, etc.), additional surface coatings can provide additional protection for the LOGO.

● Clear coating: Clear coating is usually used to protect the ink surface from friction and external physical damage. Clear coating not only improves scratch resistance, but also enhances the durability of the LOGO. The addition of coating can also provide multiple protections such as anti-ultraviolet and anti-moisture.

● Varnish coating: Varnish coating is a common means of protection for printed products. It can provide a glossy effect for the LOGO, making the printing effect more vivid and anti-fading.

● Anti-UV coating: Anti-UV coating can effectively block UV radiation, thereby preventing the LOGO from fading due to UV radiation.

With reasonable coating protection, the LOGO on the tin plate cans can be more durable, extend its service life, and maintain a bright appearance.

How long does the tin plate cans LOGO fade?

Under normal storage conditions, how long can the tin plate cans LOGO remain bright?

Depending on the different ink types, coating protection and storage conditions, the service life of the LOGO on the tin plate cans under normal conditions will vary. Generally, a properly protected tin plate cans LOGO can remain non-fading for 3 to 5 years in a cool and dry environment indoors.

However, if exposed to direct sunlight, humidity, extreme temperatures and other environments, the fading speed of the tin plate cans LOGO will be greatly accelerated. Under unsuitable environmental conditions, the fading time of tin plate cans LOGO may be shortened to a few months to about a year.

How can brands ensure the durability of tin plate cans LOGO?

Many well-known brands will ensure the long-term brightness of tin plate cans LOGO by selecting high-quality inks and adding appropriate protective layers when designing packaging. In addition, tin plate cans manufacturers will also provide different storage suggestions based on market demand to help consumers extend the service life of the product.

Brands can ensure the durability of tin plate cans LOGO through meticulous packaging design, thereby enhancing the brand image and market competitiveness of products.