As a key packaging material widely used in food, beverage, chemical, pharmaceutical and other industries, tin plate sheet occupies an important position in many fields due to its excellent corrosion resistance and good processability. However, many people know little about the production process of tinplate sheet.

This article will comprehensively explain the production process of tin plate sheet, including the selection of raw materials, processing steps and key process parameters, to help readers gain an in-depth understanding of the complex process behind this material.

What is tinplate sheet?

Before we delve into the production process, we first need to understand what tinplate sheet is. Tin plate sheet is a composite material composed of a layer of metallic tin on the surface of a low-carbon cold-rolled steel sheet. As a substrate, the steel sheet provides good mechanical strength and ductility, while the tin layer on the surface gives the material excellent corrosion resistance and decorative properties. Therefore, tinplate sheet combines the strength of steel and the corrosion resistance of tin, making it an ideal packaging material for food, chemical and daily necessities.

The most common production method of tinplate sheet is the electrolytic tinning process, which is an efficient and precise electroplating technology that can deposit a uniform and controllable tin layer on the surface of the steel sheet. Next, this article will introduce the production process of tin plate sheet and the technical points of each step in detail.

What is the production process of tin plate sheet?

The production process of tin plate sheet includes raw material preparation, cold rolling, pickling, annealing, electroplating tinning and post-processing. These links cooperate with each other to ensure the quality and performance of the final product.

Raw material preparation

The starting point of tinplate sheet production is high-quality low-carbon steel coils. These steel coils are usually further cold-rolled from hot-rolled steel plates, with high strength and good ductility. The thickness of the steel plate is usually controlled between 0.12 and 0.50 mm, which provides the basis for the thin and strong characteristics of the final product.

The selection of low-carbon steel is crucial because it not only determines the strength of tin plate sheet, but also affects the toughness and processing properties of the material. To ensure the smooth progress of the production process, steel coils are usually subject to strict quality inspections before entering the production line, including thickness, surface quality and chemical composition.

Pickling and cleaning

Before electroplating tin, the surface of the steel plate needs to be kept very clean, so pickling is an essential step. There are often scales, oil stains and impurities on the surface of steel plates, which will affect the effect of tin plating. The main purpose of the pickling process is to remove these surface impurities and keep the surface of the steel plate clean.

Pickling is usually carried out with dilute hydrochloric acid. Under certain temperature and acid concentration conditions, the steel plate passes through the pickling tank, and the surface oxide layer and dirt are completely removed. After pickling, the steel plate is washed and dried to ensure that there is no residual acid on its surface to prevent it from affecting the subsequent process.

Cold rolling and annealing

The pickled steel plate is further cold rolled to achieve the required thickness and surface finish. The cold rolling process is carried out at room temperature, which can effectively reduce the thickness of the steel plate and make its grain structure finer, thereby enhancing the mechanical strength of the material.

However, the cold-rolled steel plate will become brittle due to cold work hardening during the rolling process, so annealing is required. Annealing is a heat treatment process that restores toughness to the internal structure of the steel plate by heating the steel plate to a certain temperature and maintaining it for a period of time, and then slowly cooling it. Annealing not only improves the ductility of the steel sheet, but also eliminates the internal stress during the cold rolling process, making the steel sheet easier to form and process in subsequent processes.

Electroplating tinning process

Electroplating tinning is the core step in the production of tin plate sheets. After pickling, cold rolling and annealing, the steel sheet enters the electroplating line. During the electroplating process, the steel sheet serves as the cathode and pure tin serves as the anode. The tin is evenly deposited on the surface of the steel sheet through an electrochemical reaction in the electrolyte.

The key parameters in the electroplating process include current density, tinning time, temperature and concentration of the tin solution. Precise control of these parameters ensures uniform thickness of the tinned layer, good surface finish, and firm adhesion of the tin layer to the substrate. The thickness of the tinned layer is usually between 0.38 and 2.2 g/m2, which can be flexibly adjusted according to the end use.

During the electroplating process, some additives are also added to improve the brightness and uniformity of the tinned layer. After electroplating, a very thin but uniform tin layer will be formed on the surface of the steel plate, which can not only effectively prevent the oxidation and corrosion of the steel plate, but also has good decorative properties.

Passivation treatment

The tinplate sheet after tinning needs to be passivated to improve the corrosion resistance of the tin layer. Passivation treatment usually uses chemical agents to form a very thin oxide film on the surface of the tin layer. This oxide film can effectively prevent the tin layer from oxidizing during storage and use, thereby enhancing the anti-corrosion performance of the tin plate sheet.

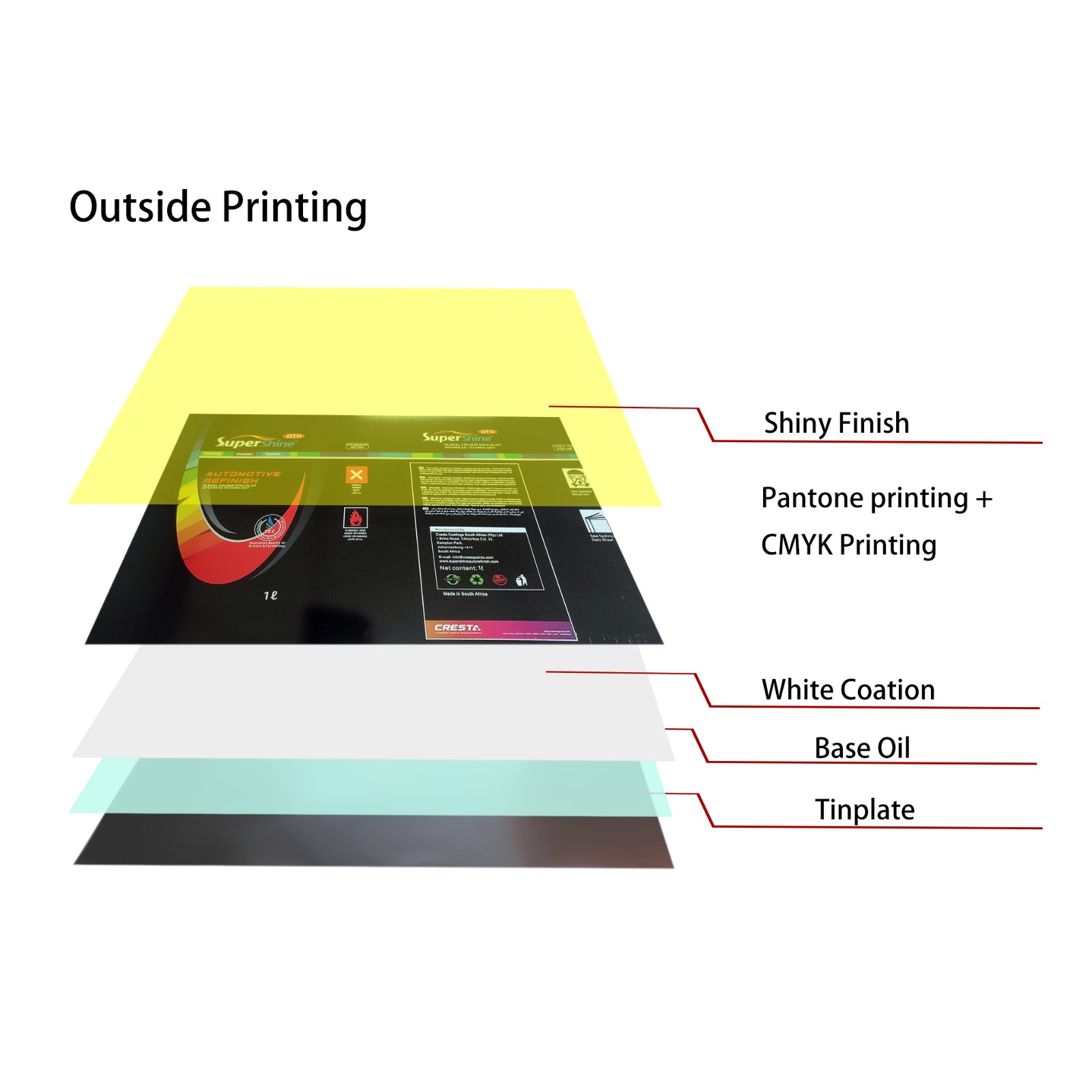

Passivation treatment can not only increase the durability of the material, but also improve the adhesion of the surface coating. For tin plate sheets that require further processing such as printing or coating with a protective film, passivation treatment is a key step to ensure the smooth progress of subsequent processes.

Lubrication and oiling

After passivation treatment, the tinplate sheet must also be lubricated. This is to ensure that the material will not be damaged by excessive friction during subsequent stamping, shearing and forming. Lubrication treatment usually uses oiling to apply a very thin layer of mineral oil or synthetic oil on the surface of the tin plate sheet. This oil film can not only effectively reduce friction, but also prevent the tin layer from oxidizing during storage.

The process requirements for oiling are very strict, and the uniformity and appropriate thickness of the oil film must be ensured. An oil film that is too thick will affect the subsequent printing or coating process, while an oil film that is too thin will not provide sufficient lubrication and protection. Therefore, the oiling process requires precise control and testing equipment.

How to control the production quality of tinplate sheet?

The production process of tin plate sheet is complex and involves multiple links, so quality control is crucial throughout the production process. To ensure that the process of each link meets the standard requirements, manufacturers usually use online monitoring systems and multiple quality inspection methods. The following are common quality control measures in the production process of tin plate sheet:

Thickness detection

During the cold rolling process, the thickness of the steel plate is a key indicator. Too thick or too thin will affect the performance of the final product. To this end, online thickness detection equipment is used in the production process to monitor the thickness of the steel plate in real time, and adjust the rolling mill parameters according to the test results to ensure that each roll of steel meets the specification requirements.

Tin coating thickness detection

The thickness of the tin coating is an important factor affecting the anti-corrosion performance of tin plate sheet. Therefore, in the electroplating tinning process, precision instruments such as X-ray fluorescence detectors (XRF) are usually used to detect the thickness of the tin layer in real time. Any product with uneven thickness or out of tolerance will be automatically rejected.

Surface quality inspection

The surface quality of tin plate sheet is directly related to its decorative performance and the smoothness of subsequent processing. In production, an automatic optical inspection system (AOS) is used to detect defects on the surface of the steel plate, such as scratches, stains, bubbles, etc. Once surface defects are found, the production line will automatically stop and process them.

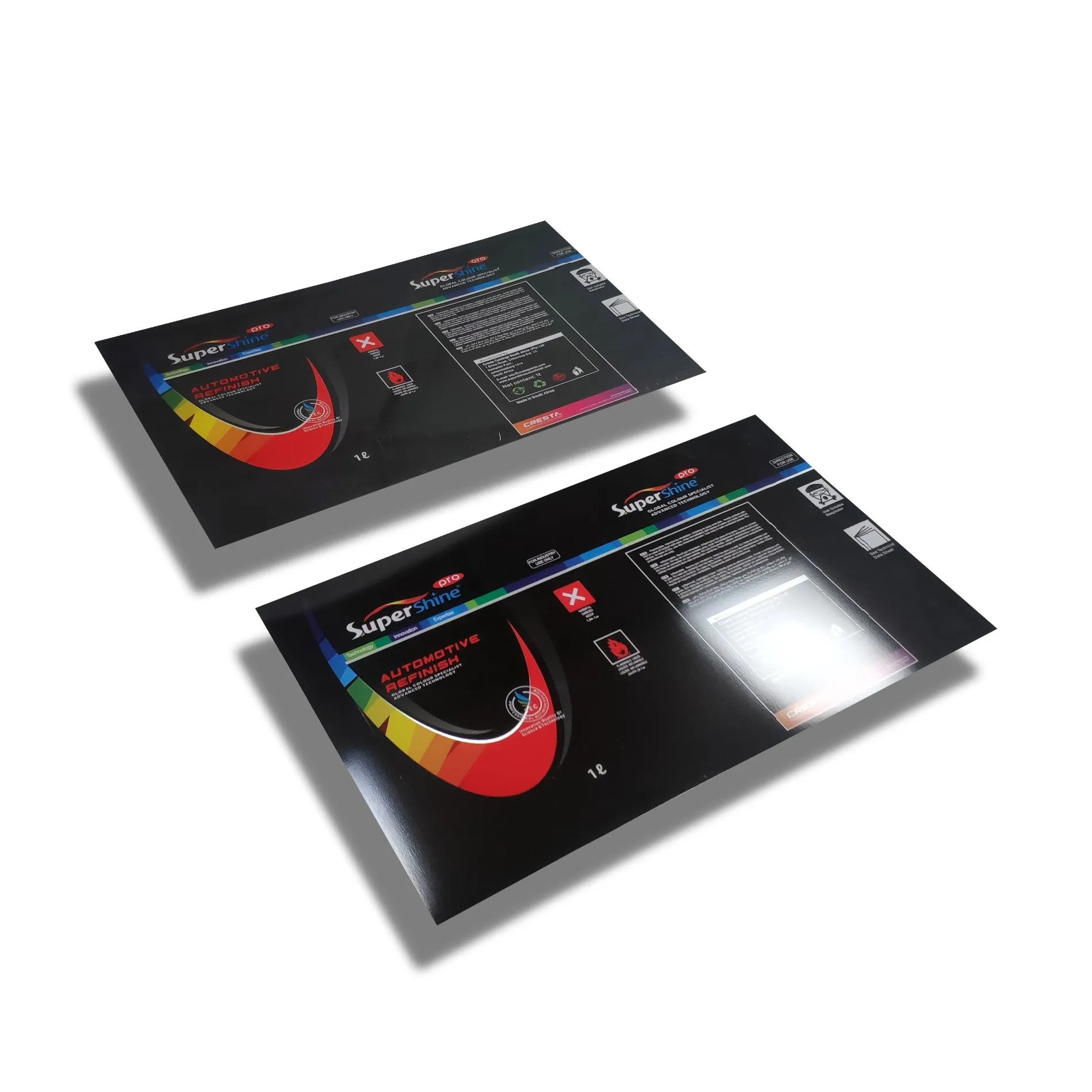

Subsequent processing and application of tinplate sheet

After the above process steps, the production process of tin plate sheet is basically completed, and then subsequent processing such as cutting, stamping, painting or printing will be carried out according to customer needs. These processes enable tin plate sheet to form various forms of products, such as food cans, beverage cans, chemical containers, etc., according to different uses and market needs.