09-09/2025

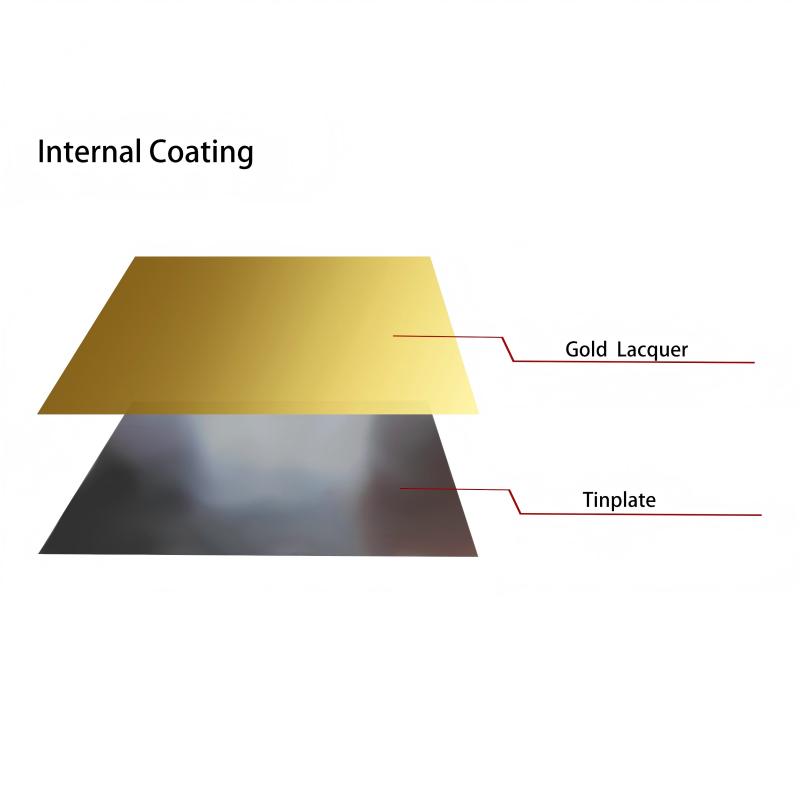

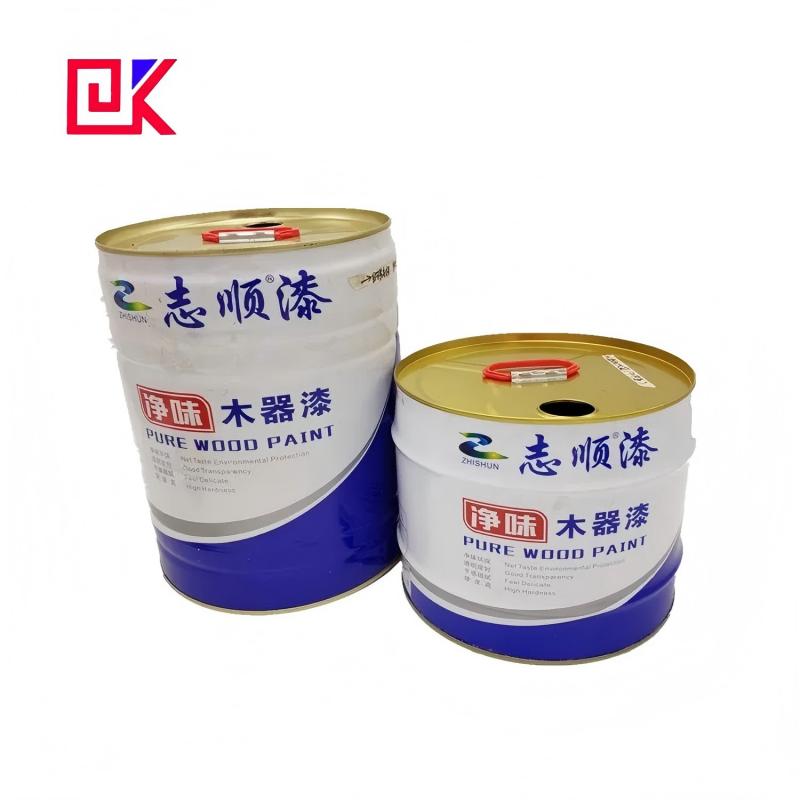

The recycling process for tinplate cans is relatively simple, and the recycling rate is very high. Recycled tinplate cans are first cleaned and treated to remove impurities. The metal is then melted to extract the iron and tin. These extracted metals can be reused in the manufacture of new metal products.