Since its invention in the early 19th century, tin can packaging continues to play a vital role in the packaging of various goods. Tin can packaging is ubiquitous in our daily lives, such as food cans, beverage cans, cosmetic containers, and various chemical product packaging.

Tin can packaging is widely used due to its strength, durability, and airtightness, but people often question its cost. Is tin can packaging expensive?

This article will delve into what tin can packaging is, its production costs, and its market pricing.

What is tin can packaging?

Tin can packaging is a packaging container made of metal materials such as iron or steel. Tin cans are typically made of tinplate, a thin, specially treated steel sheet coated with tin for rust and corrosion resistance. Tin can packaging comes in many varieties, primarily used to preserve and protect a wide range of products, from food and beverages to cosmetics and chemicals.

A typical tinplate can package consists of a can body, a lid, and a sealing device. The can body is typically connected to the lid by welding or crimping to ensure a high degree of sealing. Depending on the nature and requirements of the packaged product, tinplate cans can be manufactured in a variety of shapes and sizes, such as round, square, and oval.

Tinplate cans not only offer excellent physical properties but also effectively protect the contents from environmental hazards such as light, oxygen, and moisture. Especially for food and beverage packaging, the can's airtightness and barrier properties effectively extend the shelf life of products while preserving their freshness and flavor.

What is the cost structure of tinplate can packaging?

The production of tinplate cans involves multiple process steps, and the complexity of these processes and the properties of the materials used directly affect the price of the can.

1. Raw Material Cost

The primary raw material for tinplate cans is tinplate. Tinplate is a low-carbon steel material that is rolled into thin sheets and then coated with tin to enhance its corrosion resistance. Due to the abundance of steel, the raw material cost of tinplate is relatively low. However, the price of tinplate is affected by fluctuations in the steel market, so raw material prices may fluctuate.

In addition, to improve the performance of tinplate cans, various coatings are applied to the interior and exterior of the cans. These coatings enhance the cans' corrosion resistance, chemical resistance, and aesthetics. Different coating materials and processes affect the cost of the cans. This is especially true for applications such as food and cosmetics, where packaging hygiene is paramount. The coating materials used must be food-grade certified and are generally more expensive than standard coatings.

2. Cost of Manufacturing Process

The manufacturing process of tinplate cans is another important factor in determining their cost. Generally speaking, the production process includes the following main steps:

• Cutting and Forming: The tinplate sheet is first cut to the desired size and then mechanically formed into the basic shape of the can body through stamping, stretching, or bending. This process requires high precision equipment and sheet quality, and complex can shapes increase the difficulty and cost of processing.

• Welding and Sealing: The body and lid of a tinplate can are typically sealed by welding or crimping. The quality of the welding process determines the sealing performance and strength of the tin can. To ensure airtightness and corrosion resistance, surface treatment is required after welding to prevent leaks and rust at the joints of the can body.

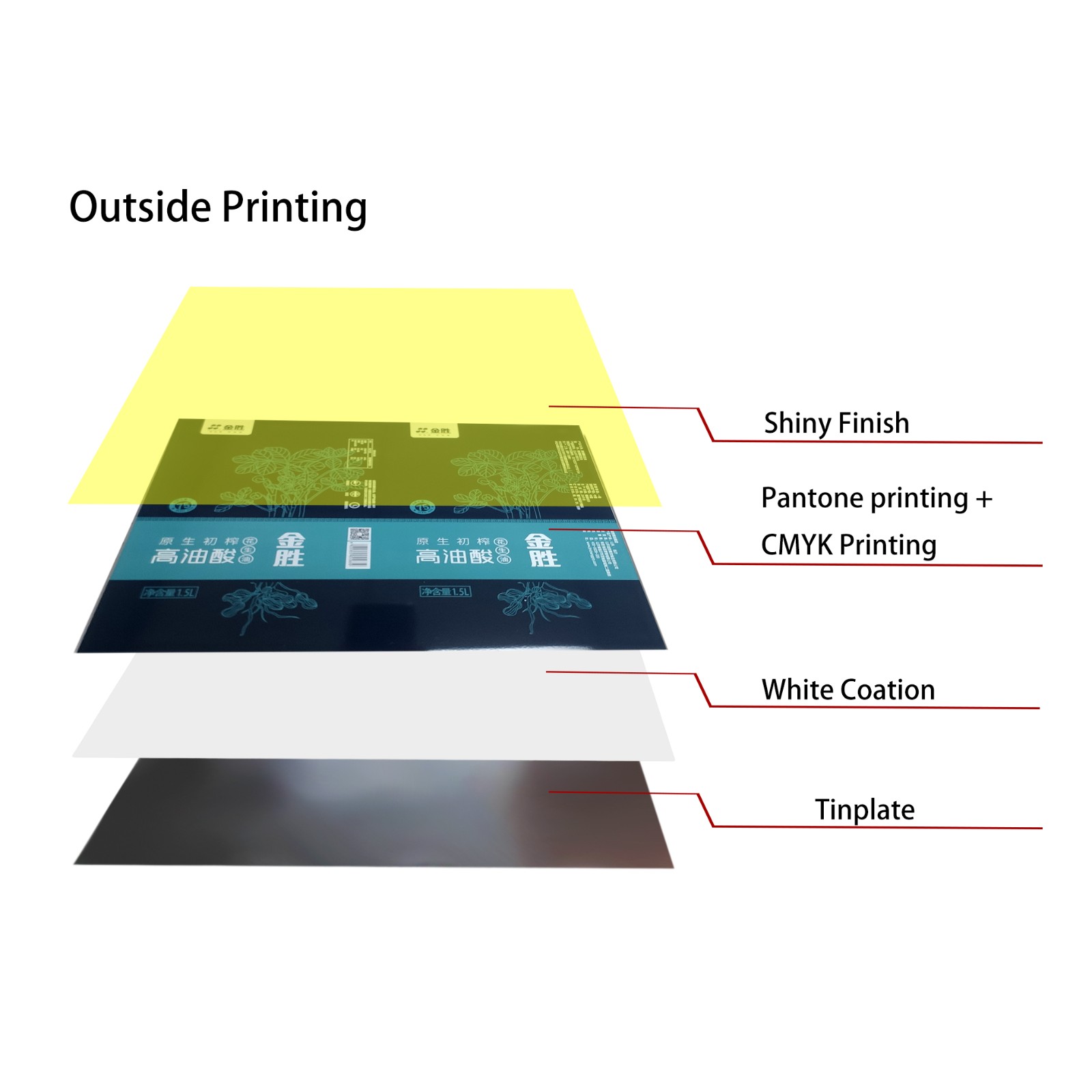

• Coating and Printing: The interior and exterior surfaces of tin cans are typically coated with protective coatings. The interior coating prevents direct contact between the contents and the metal, preventing chemical reactions; the exterior coating provides decorative effects and enhances the packaging's appearance. The complexity of the coating process, the choice of coating, and the requirements for the printing process significantly affect the cost of the tin can. For example, food-grade tin cans require coatings and inks that meet food safety standards, which are relatively expensive.

• Testing and Quality Inspection: Tinplate cans undergo rigorous testing during the production process to ensure that their sealing, strength, and corrosion resistance meet standards. This step increases costs, but it is also crucial for ensuring the quality of tinplate can packaging.

3. Packaging and Transportation Costs

Tinplate cans are sturdier than plastic and paper packaging, but they are also heavier, which means that shipping tinplate cans increases logistics costs. Especially when transporting large quantities of tinplate canned products globally, transportation costs can be high due to their weight and volume. Furthermore, tinplate cans require special protection during transportation to prevent deformation or damage from collisions and crushing.

4. Labor and Equipment Costs

The production process of tinplate can packaging involves a large amount of automated equipment and manual labor. From cutting and forming raw materials to welding, printing, and quality inspection, each step requires sophisticated machinery. The purchase, maintenance, and upgrades of this equipment incur certain costs. Furthermore, the labor costs of the skilled workers and engineers who operate this equipment also affect the price of tinplate can packaging.

What Factors Affect the Price of Tinplate Can Packaging?

After understanding the cost structure of tinplate can packaging, we can further analyze its market pricing. The price of tinplate can packaging is influenced by many factors, with the following being particularly important:

1. Packaging Application and Specifications

The price of tinplate cans depends largely on their specific application and specifications. Industries such as food, beverages, and cosmetics have high hygiene and safety requirements for tinplate cans, requiring the use of materials and processes that meet stringent standards. Consequently, the cost of tinplate packaging in these sectors is relatively high. Tin can packaging for chemical products, on the other hand, has a lower cost due to the relatively low hygiene requirements for the contents.

Also, the specifications and shape of tinplate cans also affect the price. Larger, more complex cans require more sophisticated processing techniques and equipment, which increases production costs. Furthermore, customized can packaging, such as special printing or custom designs, will increase the base price.

2. Production Batch and Scale

Tinplate can packaging production has a strong economy of scale. Generally, mass production spreads the production cost of each product, so the unit price of large-scale cans is much lower than that of small-batch custom cans. For many manufacturers, large-scale production effectively reduces costs and allows them to be supplied to the market at a lower price.

3. Market Competition and Raw Material Prices

The market price of tinplate packaging is also affected by global market competition and fluctuations in raw material prices. Steel, the primary raw material for tinplate, is subject to global economic conditions and supply and demand. For example, when steel prices rise, the cost of tinplate also increases, inevitably leading to a price increase for tinplate packaging. In addition, competition in the packaging industry also has a certain regulatory effect on tinplate can prices. Faced with fierce market competition, tinplate can manufacturers often strive to maintain price competitiveness by improving production efficiency and reducing production costs.

What are the advantages and disadvantages of tinplate can packaging?

1. Advantages of Tinplate Can Packaging

• Sealing and Durability: Tinplate can packaging offers excellent sealing properties, effectively blocking air, moisture, and light, protecting the quality of the contents and extending their shelf life.

• High Strength: Tinplate cans are sturdy and durable, resistant to external impact and pressure, protecting the products inside from damage.

• Recyclability: Tinplate cans are environmentally friendly and can be recycled and reused, helping to reduce resource waste and environmental pollution.

• High Printability: Tinplate cans can be printed with complex patterns on their exterior, enhancing the visual appeal of products.

2. Disadvantages of Tinplate Can Packaging

• Heavy: Compared to plastic and paper packaging, tinplate cans are heavier, increasing transportation and storage costs.

• Higher Price: Due to the complex manufacturing process and high raw material costs, tinplate cans are more expensive than other packaging options.

• Rust: Although tinplate has an anti-corrosion coating, it still has the risk of rusting in certain environments, especially when the coating is damaged.

Is tinplate can packaging expensive?

Based on the above discussion, the price of tinplate can packaging is determined by multiple factors. While the manufacturing process is complex, the material costs are high, and transportation costs are relatively high, its excellent performance, environmental friendliness, and wide range of applications make it a cost-effective packaging option. In certain industries, such as food and cosmetics, where demanding product packaging is required, tinplate cans may be more expensive than other packaging materials. However, their value lies in their superior protection, sealing properties, and enhanced brand image.

Is it cheaper to buy tinplate packaging directly from a China manufacturer?

Yes, buying directly from a Chinese supplier like Dekai offers significant cost savings. Our in-house production, bulk material purchasing, and efficient processes allow us to offer cheap yet premium metal packaging solutions. Skip the middlemen and source directly from our Foshan factory for lower prices, fast lead times, and full customization.