Metal packaging cans, as an essential component of the modern packaging industry, are widely used in a variety of fields, including food, beverages, cosmetics, pharmaceuticals, and chemicals. These metal packaging cans play an irreplaceable role in protecting products, extending shelf life, and facilitating transportation and storage.

However, corrosion of metal cans—also known as rust—is often a key factor affecting their service life and product safety. So, which metal packaging cans are prone to rust? Which are not? Understanding these issues not only helps select the appropriate metal packaging can material but also helps better manage and maintain the quality of canned products.

What are the principles of metal corrosion and rust?

Corrosion is the phenomenon in which metals lose their original properties through chemical reactions, typically when exposed to moisture, oxygen, acids, bases, or other chemicals in the environment. Rust is the formation of iron oxide when iron and its alloys (such as steel) react with oxygen and water in a humid environment. This often manifests as a reddish-brown rust layer on the surface.

Rust is a specific form of corrosion, specifically the oxidation of iron or steel. While the oxides produced by corrosion of other metals, such as aluminum, copper, and tin, are not called "rust," their corrosion can negatively impact the structure and function of metal packaging cans.

Which metal packaging cans are prone to rust?

Rust-prone metal packaging cans:

1. Ordinary iron cans

2. Carbon steel cans

1. Ordinary iron cans

Ordinary iron cans, those made of iron or steel without special protective treatments, are among the most susceptible to rust. Iron readily oxidizes in the presence of air and water, forming iron oxide, commonly known as rust.

Ordinary iron cans are particularly susceptible to rust in humid environments, especially when storing products containing moisture, acidity, or salt. This corrosion is accelerated. Rust not only compromises the structural integrity of the can but can also penetrate through the can wall, contaminating food or other packaged contents.

For this reason, ordinary iron cans are rarely used directly in the modern packaging industry. Instead, they are typically treated with coatings or other corrosion protection techniques to enhance their corrosion resistance.

2. Carbon Steel Cans

Carbon steel is a common type of steel, primarily composed of iron and carbon. While carbon steel has greater hardness and strength than ordinary iron, since it's still primarily iron, it's still susceptible to rust in humid or corrosive environments.

Carbon steel cans typically require surface treatments such as galvanizing or tinning, or a protective coating, to effectively resist corrosion. If the surface coating of a carbon steel can is damaged, the exposed carbon steel remains susceptible to reaction with oxygen and moisture in the air, leading to rust.

Therefore, during packaging, the storage and transportation conditions of carbon steel cans must be strictly controlled to prevent damage to the surface coating and the occurrence of metal corrosion.

Which metal packaging cans are rust-resistant?

Rust-resistant metal packaging cans:

1. Aluminum cans

2. Stainless steel cans

3. High-quality tinplate cans

1. Aluminum cans

Aluminum cans are one of the most widely used metal packaging cans in the beverage packaging industry today. Aluminum has excellent oxidation resistance. When exposed to air, it forms a dense protective aluminum oxide film. This film effectively prevents further oxidation, making aluminum cans rust-resistant.

Aluminum cans also offer advantages: lightweight, excellent thermal conductivity, and exceptional corrosion resistance. Even when storing acidic or alkaline beverages, aluminum cans maintain excellent corrosion resistance. Although aluminum cans are often coated to enhance their sealing and aesthetics, even minor damage to the coating prevents them from rusting or corroding as quickly as iron cans.

For this reason, aluminum cans are very popular for packaging liquids such as beverages and beer, and are particularly suitable for the long-term storage of carbonated beverages.

2. Stainless Steel Cans

Stainless steel is an alloy composed of iron, chromium, and nickel, offering exceptional corrosion resistance and durability. Unlike ordinary steel, stainless steel contains a certain proportion of chromium. When chromium comes into contact with oxygen in the air, it forms a dense protective chromium oxide layer on the surface. This layer effectively inhibits the oxidation of the iron, thereby preventing rust.

Stainless steel cans not only have good corrosion resistance in food and beverage packaging, but are also widely used in the fields of medicine, chemical industry, etc. Stainless steel cans are an ideal choice when storing highly corrosive chemicals. Although the cost of stainless steel cans is relatively high, their excellent rust resistance and durability make them the preferred material for high-end product packaging.

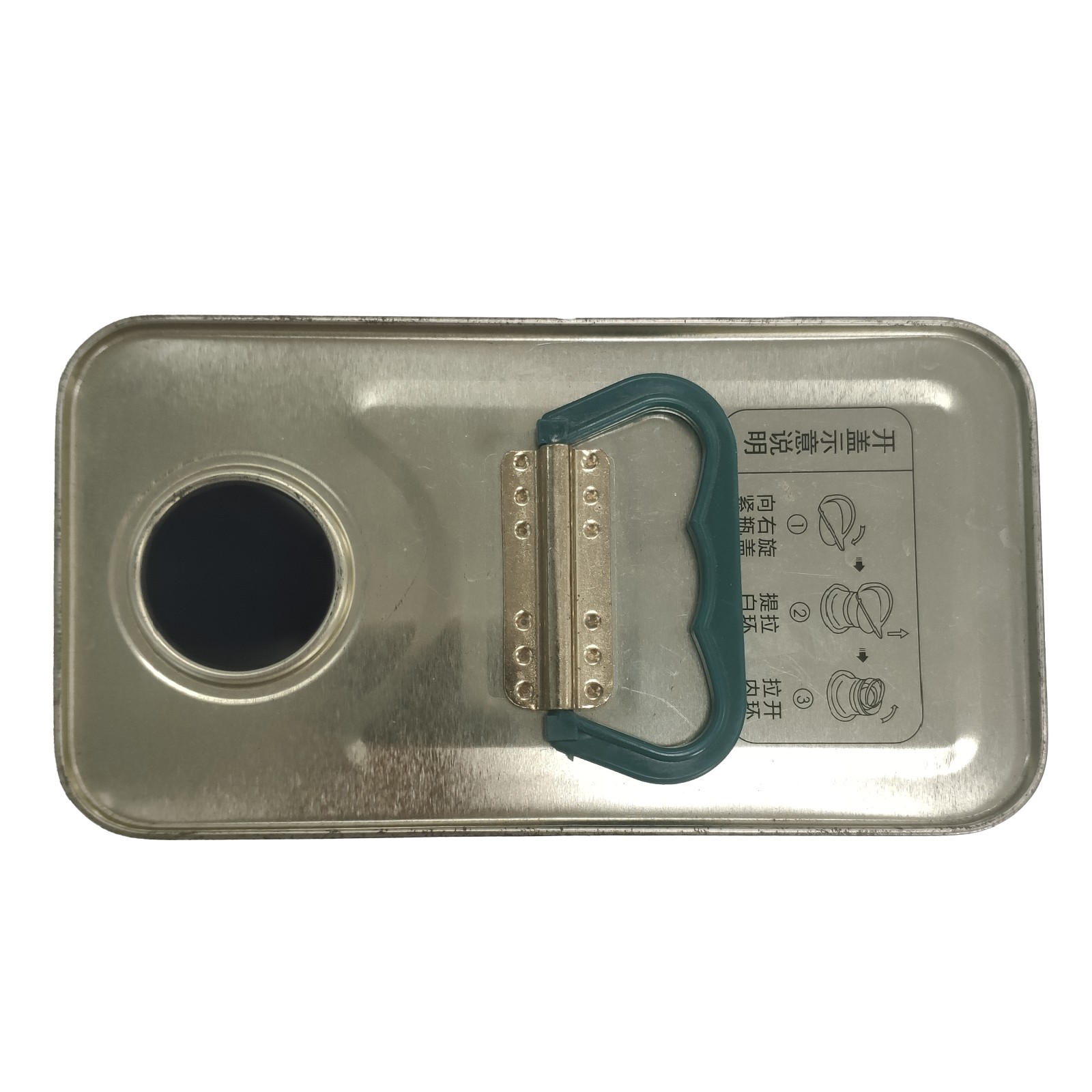

3. High-quality tinplate cans

Tinplate cans. Its essence is that a layer of metal tin (Sn) is plated on the surface of steel plate (iron). Tinplate cans have stronger corrosion resistance, especially in high humidity or high acid and alkaline environments. They are more stable. Tinplate cans are usually used for packaging cosmetics, medicines and high-end foods to ensure that the products are not affected by metal corrosion during long-term storage.

(1) Will tinplate packaging cans rust?

• Under normal circumstances: the outer layer of tin separates the iron, and the iron will not directly contact the air/water, so it is not easy to rust.

• Once the tin layer is damaged or scratched: the iron is exposed and will rust quickly.

• Electrolytic corrosion of tin and iron: The potential of tin is higher than that of iron. If the tin layer is damaged, the iron and tin will form a galvanic corrosion, and the iron will accelerate rusting (this is different from galvanized steel sheets. Zinc is more active than iron and can protect iron as a "sacrificial anode").

(2) Will tinplate packaging cans oxidize?

• The tin layer itself: It will slightly oxidize to form a dense layer of tin oxide (SnO₂), but this oxide film is very thin and relatively stable. It will not peel off over a large area, but can protect the metal underneath.

• Iron substrate: As long as the tin layer is intact, it will basically not oxidize; but once the tin layer is damaged, the iron will be quickly oxidized (rusted).

However, if high-quality tinplate iron cans are used, its rust resistance will be greatly improved. Dktinplate is a national high-tech enterprise integrating R&D, production, sales and service. It provides one-stop metal packaging services, covering diversified businesses such as raw materials, metal printing, aerosol can production, top and bottom cover production, etc.

What are the environmental factors that affect the rusting of metal packaging cans?

In addition to the inherent characteristics of metal packaging cans, environmental factors also significantly influence the speed and extent of rust. Even rust-resistant metal packaging cans can suffer varying degrees of corrosion if exposed to extreme environments. Therefore, the following environmental factors should be paid special attention to when handling and storing metal packaging cans:

1. Humidity

Humidity is one of the main factors that cause metal packaging cans to rust. In high humidity environments, moisture in the air is more likely to come into contact with the metal surface, promoting oxidation reactions. Consequently, metal packaging cans, especially iron and carbon steel cans, are more susceptible to corrosion in humid environments.

To prevent the effects of humidity on metal cans, avoid storing metal cans in humid environments when packaging products, or use moisture-proof packaging materials to isolate them from moisture.

2. Acidic and Alkaline Substances

Contact with acidic or alkaline substances often accelerates the corrosion process. For example, acidic components in foods (such as tomatoes and lemons) or carbonic acid in beverages can chemically react with the surface coating or plating of metal cans, accelerating corrosion.

Therefore, for storing products containing acidic or alkaline substances, metal packaging cans with high corrosion resistance, such as aluminum cans, stainless steel cans, or cans with special coatings, must be selected.

3. Mechanical Damage

Mechanical damage can also affect the rust resistance of packaging cans. If the surface plating or coating of metal packaging cans is mechanically damaged by impact, scratches, or other mechanical damage, the metal substrate may be exposed to air, increasing the risk of rust. Therefore, metal packaging cans should be minimized from physical damage during transportation and storage to ensure the integrity of their surface protective layer.

Is Dekai suitable for small businesses or just large-scale brands?

We serve both small and large businesses. Whether you need a customized small batch or a bulk wholesale order, we offer flexible MOQs, competitive quotes, and personalized customer service. Many clients come to Dekai for affordable yet high-quality tinplate solutions, benefiting from our China factory's efficiency and experience.