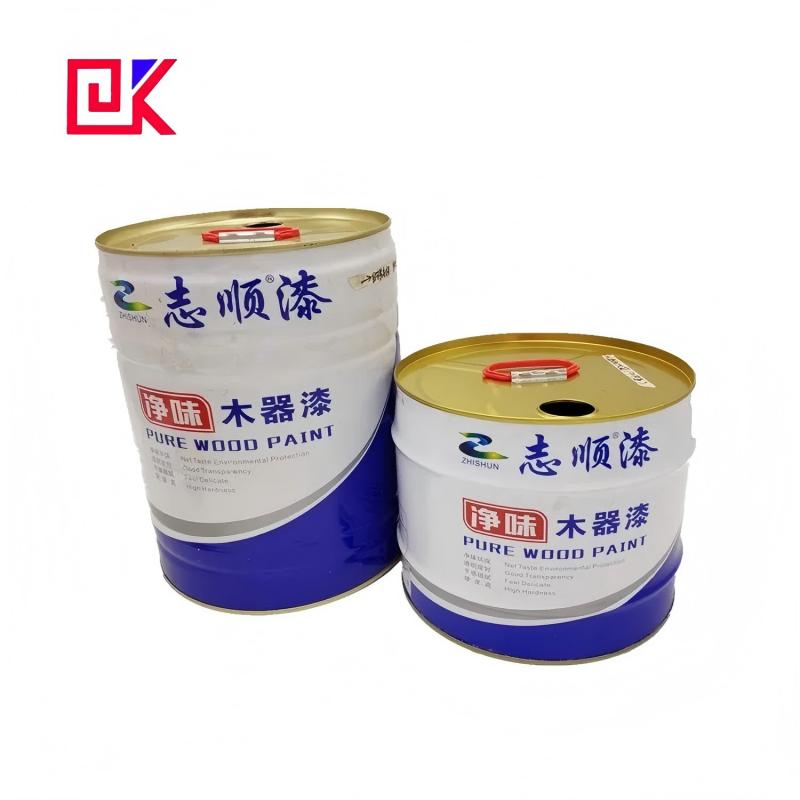

Metal packaging cans, a widely used packaging format for food, beverages, cosmetics, pharmaceuticals, and other industrial applications, have long been a vital component of the packaging industry due to their superior protection, durability, and recyclability.

Whether used in food cans, beverage bottles, aerosol cans, or other industrial products, metal packaging cans offer unique advantages.

This article will delve into what metal packaging cans are, detailing their material types, their characteristics, and why they are widely used in various packaging applications.

What are metal packaging cans?

Metal packaging cans are cans made of metal and used to hold and protect products. Compared to packaging materials such as paper, plastic, and glass, metal packaging offers superior protection and sealing properties. It effectively protects the contents from the outside world during storage, transportation, and distribution, thereby extending the shelf life of the products.

Metal packaging cans typically possess the following key characteristics:

• High strength and durability: Metal materials have high mechanical strength and toughness, maintaining the integrity of the packaging during long-term storage and transportation, preventing damage from external forces.

• Good sealing: Metal packaging cans are airtight and moisture-proof, protecting the contents from the effects of air, moisture, and ultraviolet rays, making them particularly suitable for products with demanding storage conditions.

• Recyclability: Metal packaging is highly recyclable and environmentally friendly. Most metal materials can be recycled after use, without causing long-term environmental pollution.

• Corrosion resistance: Coatings or the use of specific metal alloys can enhance corrosion resistance, making metal cans resistant to chemicals, acids, alkalis, and other substances.

What are the commonly used materials for metal packaging cans?

The materials used for metal packaging cans vary depending on the application. Typically, metal packaging cans are made of materials such as tinplate, aluminum, and tin-free steel (TFS). Each of these materials has different properties and is suitable for different packaging needs.

1. Tinplate

Tinplate is the most widely used material in metal packaging cans. Made primarily of low-carbon steel or iron, it's coated with tin, creating a sheet metal with excellent corrosion resistance. The tinplate production process typically includes cold rolling, annealing, tinning, and coating, ensuring stable performance under a variety of conditions.

Advantages of Tinplate:

• Strong Corrosion Resistance: The tin coating on tinplate effectively prevents oxidation, extending the metal's lifespan. It's particularly suitable for packaging requiring high corrosion resistance, such as food cans.

• Good Processability: Tinplate has excellent ductility and toughness, allowing it to be processed into a variety of complex shapes, such as round, square, and oval, to meet the packaging needs of a variety of products.

• Suitable for Printing and Decoration: Tinplate's smooth surface makes it suitable for multi-color printing and coating, allowing for the easy imprinting of a variety of exquisite designs and brand logos.

Typical Applications:

Tinplate is primarily used for food and beverage packaging, such as cans, tea cans, candy boxes, and coffee tins. Its excellent corrosion resistance and sealing properties ensure that food remains fresh and prevents spoilage during long-term storage. Tinplate is also commonly used in the packaging of cosmetics and pharmaceuticals, as these products place high demands on the corrosion resistance and stability of the packaging material.

2. Aluminum

Aluminum, another common metal packaging material, is widely used in beverage cans, food cans, aerosol cans, and other packaging due to its light weight, strong plasticity, and excellent corrosion resistance. Its applications are not limited to the food and beverage sector; aluminum cans are also commonly found in the packaging of industrial and chemical products.

Advantages of Aluminum:

• Lightweight: Aluminum's low density makes packaging cans relatively light, making them easier to transport and handle, thereby reducing logistics costs.

• Good corrosion resistance: The aluminum oxide layer formed on the aluminum surface offers excellent corrosion resistance and is less likely to react chemically with food or other products, ensuring product safety.

• High plasticity: Aluminum's excellent ductility allows it to be processed into various shapes and sizes to meet different packaging needs.

Typical Applications:

Aluminum is primarily used in beverage cans (such as beer cans, carbonated beverage cans, and juice cans) and aerosol cans (such as those for sprays, detergents, and personal care products). Furthermore, due to its excellent thermal conductivity, aluminum is also widely used in canned instant foods, enabling rapid heating of food.

3. Tin-Free Steel (TFS)

Tin-Free Steel, also known as tin-free steel, is a material in which a layer of chromium, rather than tin, is applied to the steel surface via an electroplating process. TFS is gaining widespread use as an alternative to tinplate in metal packaging cans.

Advantages of TFS:

• Strong corrosion resistance: Although lacking the protective tin layer, the chromium layer and chromium oxide film on TFS offer strong corrosion resistance, protecting against rust and chemical attack.

• Lower cost: Compared to tinplate, TFS has a lower production cost, making it widely used in cost-sensitive packaging applications. • Environmental friendliness: Since tin is not used, the production process is more environmentally friendly and less likely to produce harmful chemicals.

Typical Applications:

Tin-free steel is commonly used in industrial product packaging, food cans, bottle caps, spray cans, and more. While its corrosion resistance is slightly inferior to tinplate, it remains an excellent choice for applications where packaging requirements are less stringent than those for food packaging.

Why Choose Metal Packaging Cans?

Reasons for Choosing Metal Packaging Cans:

1. Strong Protection

2. Good Sealing

3. Durability and Safety

4. Ease of Recycling and Environmental Protection

Metal packaging cans offer excellent protection for their contents thanks to their unique physical and chemical properties. Compared to other materials, metal packaging cans offer many distinct advantages.

1. Strong Protection

Metal packaging cans provide excellent protection for food, beverages, pharmaceuticals, and more, shielding them from external factors such as air, moisture, and light, effectively extending their shelf life. Particularly in the food and beverage sector, metal packaging cans preserve the freshness and taste of products and prevent spoilage due to oxidation or moisture.

2. Excellent Sealing

Metal cans achieve a high degree of sealing through a sophisticated packaging process, preventing the ingress of external contaminants. Highly sealed packaging is particularly suitable for products with demanding storage environments, such as canned foods, pharmaceuticals, and cosmetics.

3. Durability and Safety

Metal cans offer superior strength and durability compared to other packaging materials, effectively preventing damage caused by external forces during transportation and storage. Furthermore, their impact resistance and high-temperature resistance ensure they remain well protected in extreme environments, ensuring the safety of their contents.

4. Easily Recyclable and Environmentally Friendly

Metal packaging cans are highly recyclable. Metal materials can be recycled and reused after use, reducing resource waste and environmental pollution. In today's emphasis on sustainable development, metal packaging is highly sought after for its environmentally friendly properties.

What is the production process for metal packaging cans?

The production process for metal packaging cans is relatively complex and typically includes the following key steps:

1. Material Processing

2. Printing and Coating

3. Forming

4. Sealing

1. Material Processing

The production of metal cans begins with material processing. Whether it's tinplate, aluminum, or tin-free steel, all materials undergo processes like cold rolling and plating to ensure sufficient strength and corrosion resistance.

2. Printing and Coating

To enhance the aesthetics and corrosion resistance of metal cans, metal can surfaces are often printed and coated. Printing allows brand logos, product information, and images to be imprinted on the can surface, while coating enhances the can's corrosion resistance.

3. Forming

The metal can forming process involves stretching, stamping, and crimping, transforming flat sheet metal into various shapes. Depending on the product's requirements, metal cans can be manufactured in shapes such as round, square, and oval.

4. Sealing

Sealing is a critical step in metal packaging cans. A specialized capping machine is typically used to seal the can body and lid together, ensuring the contents do not leak or become contaminated.

Do you offer OEM services for private labels or brands?

Yes, Dekai offers full OEM and private label services for aerosol cans, printed tinplates, and accessories like top and bottom covers. If you’re developing your own brand, our design team can help you create customized packaging solutions with low minimum orders and discount pricing. We’re more than a supplier – we’re a strategic partner in your brand’s success.