06-23/2025

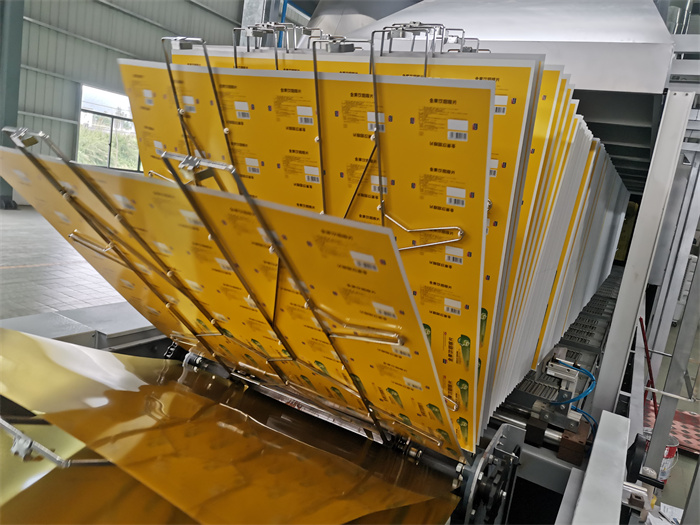

The time of this process may vary depending on the type of equipment in the production line, the complexity of the treatment process, and the quality of the tinplate sheet. Generally, the preparation takes 10 to 30 minutes, but if special surface treatments (such as anti-corrosion, anti-oxidation treatment, etc.) are required, the time may be longer.