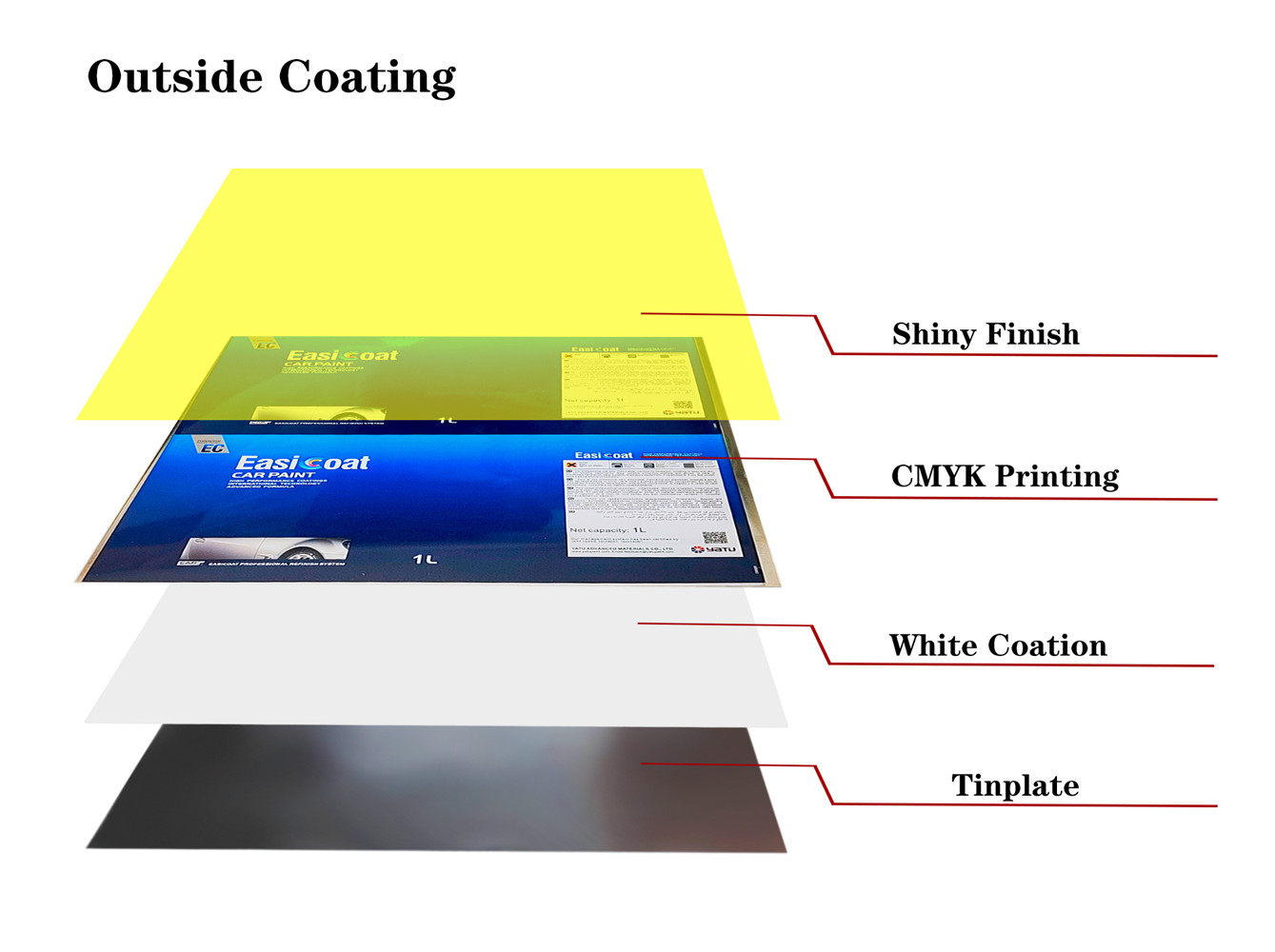

As a packaging material mainly used for food, beverages, cosmetics and other consumer products, tinplate sheets need to have excellent physical properties such as corrosion resistance and durability, as well as attractive appearance. In order to make tinplate products more competitive in the market, the printing of tinplate sheets is particularly important. Printing tinplate sheets must not only present high-quality patterns, but also ensure durability, corrosion resistance and food safety.

In printing tinplate sheets, offset printing is a common process, but it is not the only printing method. This article will explore several major printing tinplate sheet methods, including offset printing, and explain their respective characteristics, advantages and applicable scenarios to help readers better understand the printing process and technology of tinplate sheets.

What is printing tinplate sheet?

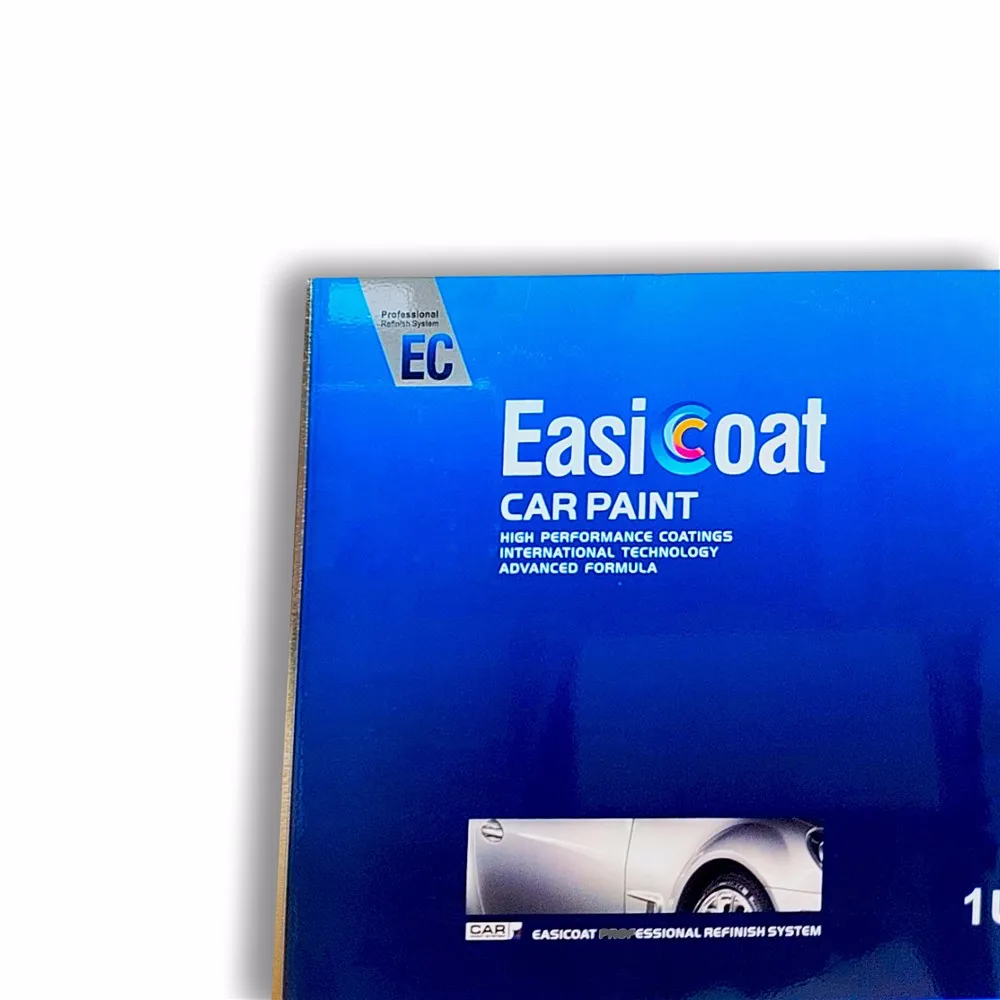

Printing tinplate sheets refers to the printing of patterns, text or colors on the surface of tinplate sheets to make them beautiful, brand logos and product information. Since the surface properties of tinplate are different from those of traditional paper or plastic materials, the printing process requires special treatment for the characteristics of tinplate.

The difficulty of printing tinplate sheet mainly lies in the smoothness, hardness and adsorption capacity of different inks of the material itself, which is significantly different from materials such as paper. Therefore, choosing the right printing process is particularly important to ensure the final printing effect.

What are the 4 methods of printing tinplate sheet?

In the process of printing tinplate sheet, several main methods include offset printing, gravure printing, screen printing and flexographic printing. These printing methods have their own characteristics and are suitable for different production needs and application scenarios. Below we will introduce them in detail one by one.

Offset printing (lithography)

Offset printing, full name offset printing (Offset Printing), is currently the most commonly used method for printing tinplate sheet. Offset printing is an indirect printing technology in which the pattern is first transferred from the printing plate to the rubber blanket, and then from the rubber blanket to the tinplate surface. The main advantages of offset printing technology are its high efficiency, precision, and ability to achieve high-quality image printing.

Offset printing process:

● Image design: First, the image is digitally designed through design software (such as Adobe Illustrator or Photoshop). After the design is completed, the pattern is transferred to the printing plate through the platemaking process.

● Platemaking: The platemaking uses photosensitive materials to make the designed pattern on the flat plate. Offset printing uses hydrophilic and oleophilic properties, and uses the repulsion principle of water and ink for printing. The ink will only adhere to the pattern area.

● Printing: The tinplate sheet is printed by pressing the rubber blanket and the printing plate, and the ink is transferred from the rubber blanket to the tinplate surface.

Advantages of offset printing:

● High quality: Offset printing can present fine patterns and high-fidelity colors, especially suitable for packaging printing that requires high-precision images and text.

● Suitable for mass production: Offset printing has high production efficiency and is particularly suitable for mass production, such as large-scale production of tinplate packaging such as food cans and beverage cans.

● Multi-color printing: Offset printing technology can achieve multi-color printing to meet the needs of complex design patterns.

Limitations of offset printing:

● High cost: Offset printing has higher plate making and equipment maintenance costs than some other printing methods.

● High ink requirements: Offset printing requires the use of special inks to ensure good adhesion to metal surfaces and have properties such as wear resistance, water resistance, and chemical corrosion resistance.

Gravure printing

Gravure printing is another common method for printing tinplate sheets. The difference between gravure printing and offset printing is that gravure printing is a direct printing technology. The pattern on the printing plate is partially recessed, and the ink is filled in the recessed area, and then the ink is transferred to the surface of the tinplate sheet by pressure.

Gravure printing process:

● Plate making: The pattern to be printed is engraved on a copper or steel printing plate. The engraved pattern part is lower than the unprinted part, that is, "gravure".

● Inking: The ink is filled into the recessed part of the printing plate, and the excess ink is scraped off by a doctor blade.

● Printing: The tinplate sheet contacts the printing plate under high pressure, and the ink is transferred from the recessed part to the tinplate surface to complete the printing.

Advantages of gravure printing:

● Rich colors: gravure printing can achieve very saturated color effects, which is suitable for packaging designs that require strong colors.

● Suitable for mass printing: gravure printing has high production speed and efficiency, and is suitable for large-scale printing tinplate sheets.

● Durable printing plates: gravure printing plates are very durable and suitable for long-term, large-scale repeated printing tasks.

Limitations of gravure printing:

● High plate making cost: gravure printing has a complex plate making process and high plate making cost, which is not suitable for small batches or short runs.

● Limited printing accuracy: Although gravure printing has advantages in color saturation, it is not as accurate as offset printing in printing fine patterns.

Screen printing

Screen printing is a relatively simple and flexible method of printing tinplate sheets, which squeezes ink onto the surface of the tinplate sheet through a screen. The characteristics of screen printing are that it is suitable for smaller batches of printing tasks and can print thicker ink layers.

Screen printing process:

● Plate making: Use mesh (usually polyester or stainless steel) to make the screen, and cover the design pattern with photosensitive material.

● Inking: The ink is squeezed through the scraper to pass through the open part of the screen and transferred to the surface of the tinplate sheet.

● Drying: After printing, the tinplate sheet needs to be dried or dried naturally to ensure that the ink layer is firmly attached.

Advantages of screen printing:

● Suitable for thick ink layer printing: Screen printing can produce thicker ink layers, which is suitable for designs that need to emphasize texture or large areas of color.

● Strong flexibility: Screen printing equipment is relatively simple, suitable for small batch production, and can be printed on tinplate surfaces of various shapes.

● Low-cost plate making: Compared with offset printing and gravure printing, screen printing has a lower plate making cost, which is suitable for personalized design and small-scale production.

Limitations of screen printing:

● Low printing accuracy: Due to the thicker ink layer of screen printing, the expression of fine patterns is poor, which is not suitable for high-precision image printing.

● Low production efficiency: Screen printing is suitable for small batch production, and its efficiency in large-scale production is not as good as offset printing and gravure printing.

Flexographic printing

Flexographic printing (Flexography) is a printing process using flexible printing plates, which is suitable for packaging printing of different materials, including tinplate sheets. Flexographic printing plates are usually made of rubber or plastic, with good flexibility and can be printed on uneven surfaces.

Flexographic printing process:

● Plate making: Use photosensitive materials to transfer the design pattern to the flexible printing plate. The flexible printing plate is elastic and can adapt to the surface changes of the tinplate sheet.

● Inking: The ink is transferred to the printing plate through the anilox roller, and then the ink is transferred to the tinplate surface through pressure.

● Printing: The tinplate sheet passes through the flexographic printing equipment to complete the printing of multi-color patterns.

Advantages of flexographic printing:

● Strong adaptability: Flexographic printing can be printed on surfaces of different shapes and materials, suitable for the printing needs of various packaging materials.

● High-speed production: Flexographic printing has high production efficiency and is suitable for large-scale and continuous production.

Limitations of flexographic printing:

● Limited image quality: Compared with offset and gravure printing, flexographic printing is lacking in image accuracy and detail, and is usually used for simpler pattern printing.

Is offset printing suitable for printing tinplate sheet?

Offset printing is the most widely used printing method for printing tinplate sheet. Since offset printing is efficient, has clear images, and is suitable for multi-color printing, it is very suitable for tinplate packaging products that require large-scale production and high printing quality. For packaging with strict appearance requirements such as food cans and beverage cans, offset printing can well present complex patterns and brand logos.

However, offset printing is not the only method suitable for printing tinplate sheet. In specific application scenarios, such as when a particularly thick ink layer is required or when printing on irregularly shaped tinplate, screen printing or flexographic printing may be more suitable. For some scenarios that require rich colors, gravure printing may be a better choice.

As a trusted name in the metal packaging industry, Foshan Dekai Metal Packaging Co., Ltd. provides innovative solutions for businesses worldwide. Located in Foshan, China, our 50,000-square-meter factory houses-edge production lines, including the FUJI PRIMEX-P453 four-color UV printing line. We specialize in printing tinplate sheets, aerosol cans, and custom packaging options, offering reliable supply for wholesale and bulk purchasing needs. With competitive pricing and a focus on efficient service, we ensure your packaging demands are met with precision. Request a quote today for tailored solutions.