In the modern packaging industry, tinplate is a widely used material, especially in the packaging of food, beverages, and chemical products. Printing tinplate gives the packaging design a richer pattern and information display, which makes it not only a functional material, but also an important carrier for displaying brand image and attracting consumers' attention. In the printing process of tinplate sheet, ink plays a key role.

So, does printing tinplate sheet require ink? The answer is yes. Ink is not only an indispensable material in the printing process, but also the core to ensure printing quality and visual effects.

What is tinplate printing?

Before we delve into the necessity of ink, we need to understand the printing process of tinplate. Tinplate is a metal material that is coated with a layer of tin on the surface of a steel plate by electrolysis or hot-dip process. Its advantages are strong corrosion resistance, plasticity and excellent surface smoothness. Therefore, tinplate is widely used in the production of food cans, beverage cans, chemical product packaging and other occasions. However, the basic tin coating alone cannot meet the market's demand for beautiful packaging and personalized brand display. Therefore, printing technology has become a key step in improving the visual effect of tinplate packaging.

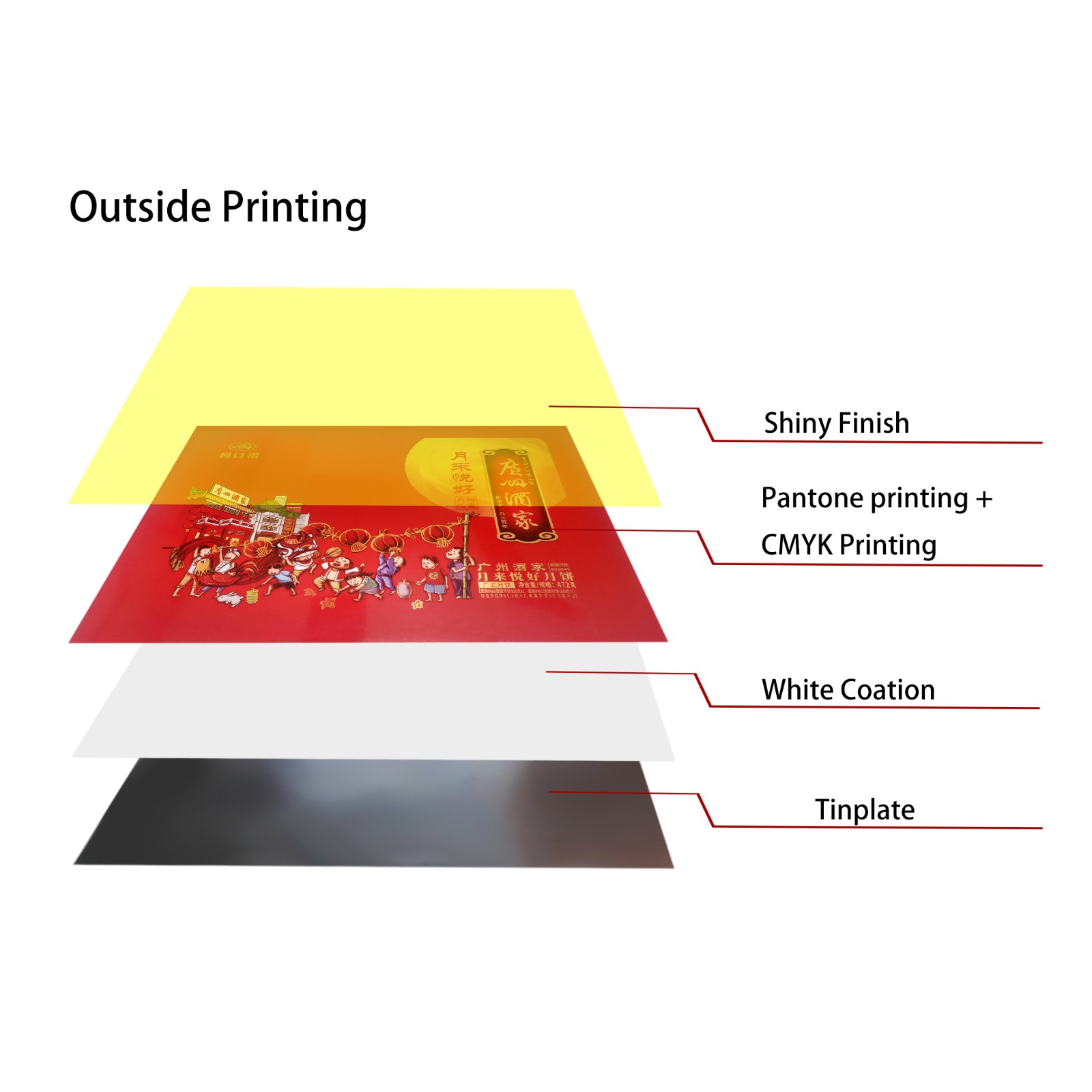

The printing of tinplate sheet is different from the printing process of flat materials such as paper. Due to its metal properties, special printing technology and materials are required, among which ink is one of the most important factors. Tinplate printing generally adopts lithographic printing technology to form rich patterns, colors and texts by transferring ink to the surface of tinplate sheet.

Why is tinplate printing inseparable from ink?

In the process of tinplate printing, ink is the medium for realizing the design pattern on the surface of tinplate. The existence of ink is not only to realize the expression of color and pattern, but also related to printing quality, material performance and the service life of the final packaging product. The following are several reasons why ink must be used for printing tinplate.

Carrier for realizing patterns and colors

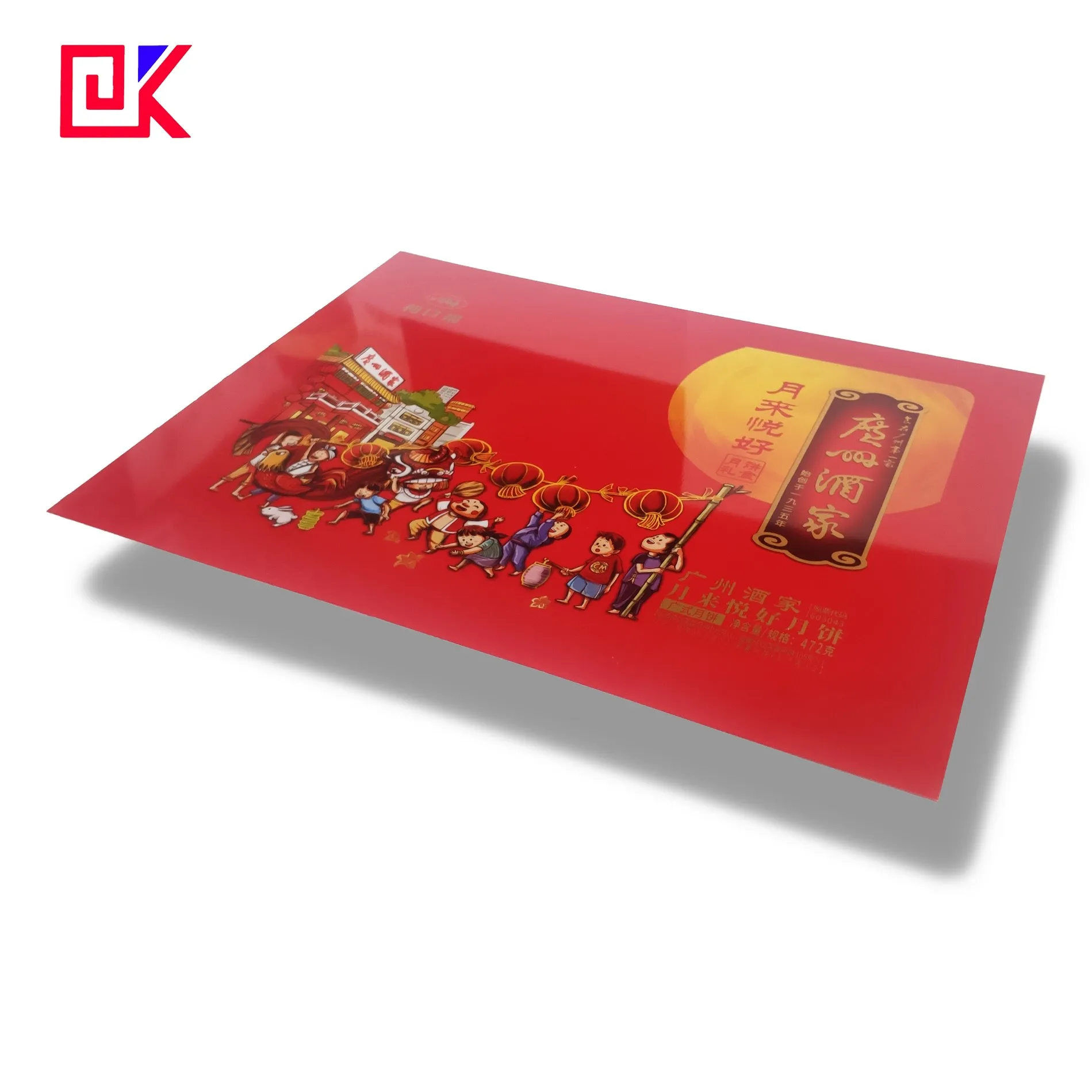

The most direct and obvious role is that ink is the core material for realizing the pattern and color of the tinplate surface. In packaging design, color and pattern are important components of brand recognition. Consumers can quickly identify products and brands through the patterns and colors on the packaging. Whether it is the brand logo of a food can or the warning information on a chemical product, the design needs to be transferred from the printing plate to the tinplate surface through ink.

The ink can be mixed into various colors according to the design requirements and present complex patterns in a fine printing method. In modern printing technology, four-color printing, spot color printing and other methods rely on different ink combinations to ensure the accuracy, brightness and saturation of the color of the printed pattern. At the same time, the ink can also produce a variety of visual effects such as gloss, matte, and metallic effects according to different process requirements, making the packaging products more attractive.

Special materials adapted to tinplate

Unlike traditional printing materials such as paper, tinplate sheet, as a metal material, has a smooth surface and does not have natural ink absorption. Traditional inks are difficult to adhere to the surface of tinplate, so inks specially designed for metal printing must be used. The ink for printing tinplate needs to have high adhesion and durability to ensure that the pattern and text will not fall off or blur during subsequent processing or use.

In addition, the printing of tinplate usually requires high-temperature baking to firmly solidify the ink on the metal surface. Therefore, the ink suitable for tinplate must also have good high temperature resistance, and maintain stable color and unchanged gloss after high temperature treatment. Special inks can better adapt to the tinplate surface through the adjustment of chemical composition, improving the printing effect and durability.

Enhance the protective performance of packaging

Printing ink is not only for beauty, it also adds an extra protective layer to tinplate to a certain extent. Although tinplate itself has good anti-corrosion properties, the thickness of the tin layer on its surface is relatively thin, and it may still be oxidized and corroded after long-term exposure to humid environments. The printed ink layer forms an additional barrier for the tinplate surface, further improving its protective performance.

Especially in the packaging of food and chemical products, the printed ink layer can effectively isolate the erosion of external air, moisture and chemicals, ensuring that the products in the package are not affected by the external environment during storage and transportation. This dual protective performance makes printed tinplate more outstanding in functionality and safety.

Improve surface smoothness and processing adaptability

During the printing process, the ink can not only give the tinplate sheet surface color and pattern, but also improve its surface smoothness and processing adaptability. After the ink layer is baked and cured, a smooth and uniform film can be formed on the surface of the tinplate. This film can reduce the surface friction coefficient and improve the adaptability of the material in subsequent processing processes, such as stamping, bending, welding, etc.

Many printed tinplate packaging materials also need to undergo secondary processing, such as deep drawing of food cans and stamping of bottle caps. In these processes, the smoothness and wear resistance of the material surface are crucial. High-quality ink can ensure that the patterns and text on the tinplate surface will not be damaged during the processing, while also reducing the wear of processing equipment and improving production efficiency.

Meet performance requirements in various environments

Tinplate packaging is widely used and may need to face various harsh environmental conditions, such as high temperature, high humidity, salt spray, acid and alkali environment, etc. In these environments, printing inks need to have special properties to ensure the durability and integrity of the printed pattern.

For example, tinplate used for food cans needs to be sterilized under high temperature and high pressure conditions, while the packaging of chemical products may need to resist the corrosion of chemicals. Therefore, tinplate printing inks need to have properties such as heat resistance, chemical resistance, and water resistance to ensure that the performance of the packaging is not affected in various extreme environments.

What are the types of inks used in tinplate printing?

Types of inks used in tinplate printing:

1. Solvent-based inks

2. UV curing inks

3. Water-based inks

There are various types of inks used in the tinplate printing process. Different types of inks have different chemical compositions and physical properties, which can adapt to different printing requirements and application scenarios.

Solvent-based inks

Solvent-based inks are one of the commonly used types of inks in tinplate printing. Its main components include pigments, resins, and solvents. The advantage of solvent-based inks is that they dry quickly and can quickly form a uniform coating on the tinplate surface. After high-temperature baking and the solvent volatilizes, the resin components in the ink are firmly bonded to the tinplate surface, thereby ensuring the adhesion and durability of the ink.

Solvent-based inks have good scratch resistance and wear resistance, and are suitable for tinplate products that require multiple processing. However, solvent-based inks release organic solvents during the production process, which may have a certain impact on the environment. Therefore, it is necessary to pay attention to environmental protection requirements and process improvements when using them.

UV curing inks

UV curing inks are a type of ink that is quickly cured by ultraviolet irradiation. Compared with solvent-based inks, UV curing inks dry faster and can be cured without high-temperature baking. This type of ink not only reduces energy consumption, but also avoids the impact of high-temperature baking on the tinplate surface, and is suitable for products that are sensitive to printing process temperature.

Another advantage of UV curing inks is that they are environmentally friendly because they do not contain volatile organic solvents, which reduces pollution to the environment. With the improvement of environmental awareness, UV curing inks are increasingly used in tinplate printing.

Water-based inks

Water-based inks use water as the main solvent and have good environmental performance. In tinplate printing, water-based inks have gradually become a substitute for solvent-based inks, especially in packaging fields with high environmental requirements, such as food, medicine and other product packaging.

Although water-based inks have an advantage in environmental protection, their drying speed is relatively slow, so more efficient drying equipment and process support are required. In addition, water-based inks have high requirements for the surface of tinplate sheet, and usually pre-treatment of the metal surface is required to improve its adhesion and drying effect.

What are the requirements for inks in tinplate printing?

In order to ensure printing quality and product performance, the inks used in tinplate printing must meet a series of technical requirements. The following are several key performance indicators of inks in tinplate printing:

Adhesion

Since the surface of tinplate sheet is smooth and does not absorb ink, the ink must have strong adhesion. The adhesion of the ink directly affects the durability and clarity of the printed pattern. If the adhesion is insufficient, the printed pattern may fall off during subsequent processing or use, affecting the quality of the packaging.

High temperature resistance

Tinplate printing usually requires high-temperature baking and curing, so the ink must have good high temperature resistance. At high temperatures, the ink should not change color, lose gloss, crack, etc., to ensure that the printed pattern still maintains good appearance and performance after high temperature treatment.

Corrosion resistance

Tinplate packaging products are often used to store food, beverages and chemical products, which have high requirements for the corrosion resistance of packaging materials. Therefore, the ink must also have a certain corrosion resistance, be able to resist corrosion from the external environment during long-term use, and maintain the integrity of the pattern.

Color reproduction

In order to ensure the color accuracy of the printed pattern, the color reproduction of the ink is crucial. Especially for brand packaging, the accuracy of color directly affects the brand image. Therefore, the ink must be able to accurately restore the color of the design pattern to ensure the consistency and stability of the packaging printing effect.