Specification of CMYK Printing Tin Plate Sheet For Gift Tins:

Product name | CMYK Printing Tin Plate Sheet For Gift Tins |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.20~0.28mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

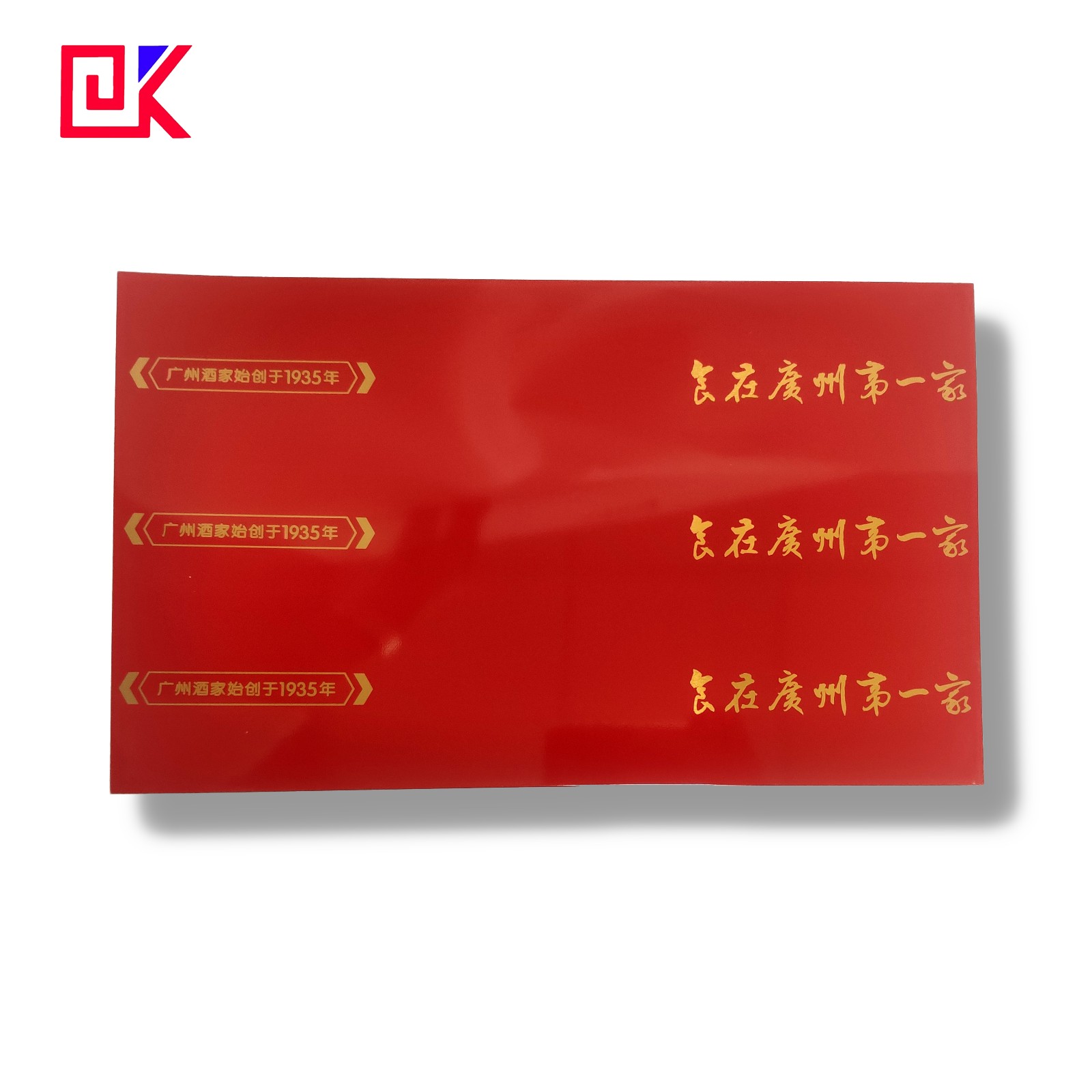

Internal coating | White coation or Gold lacquer |

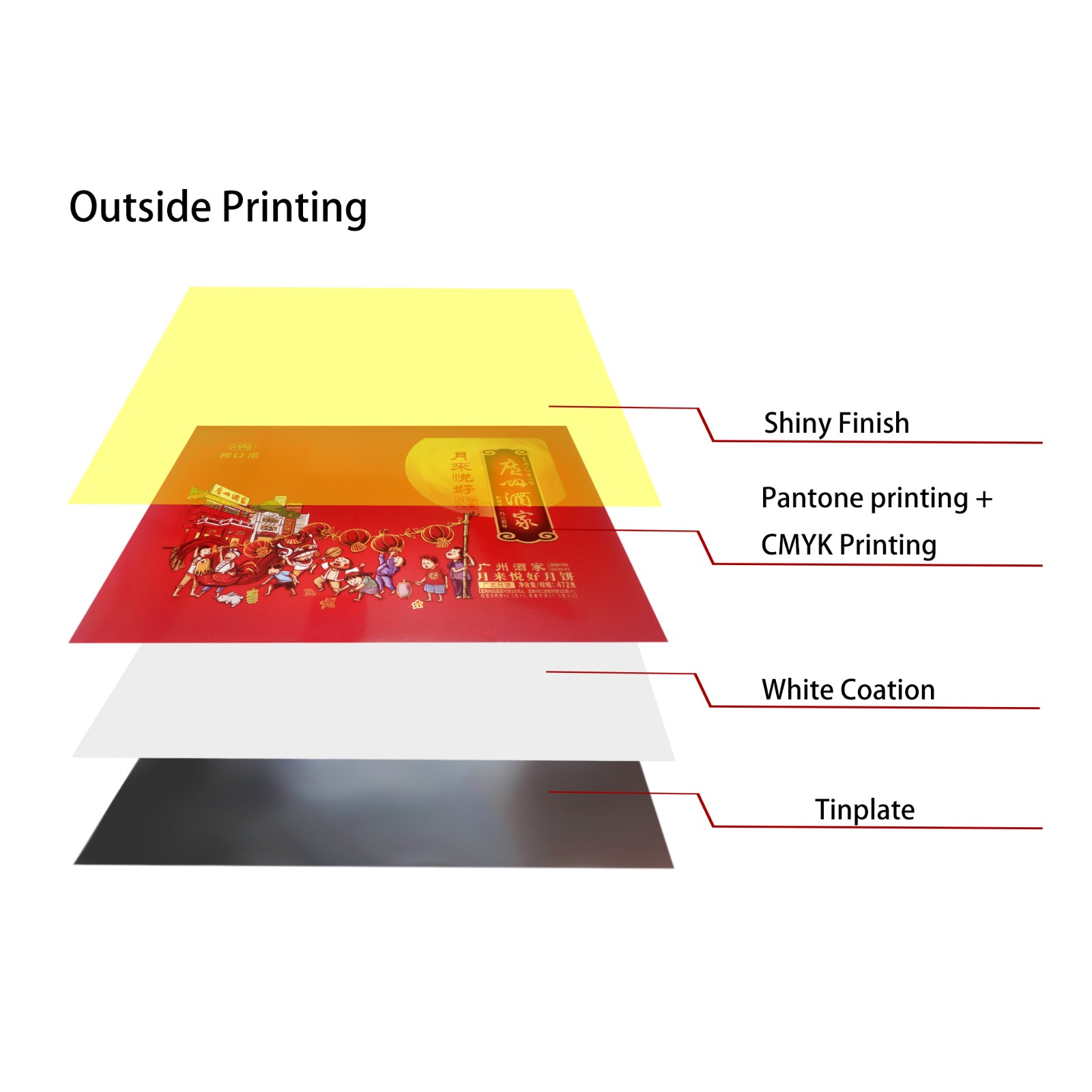

Outside printing | White coation+CMYK Printing+Matte treatment |

Application | For any gifts made of tin packing Tin,Box, Can, Bucket, tin gifts, etc(Food, oil, medicines,gift, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

Product Design

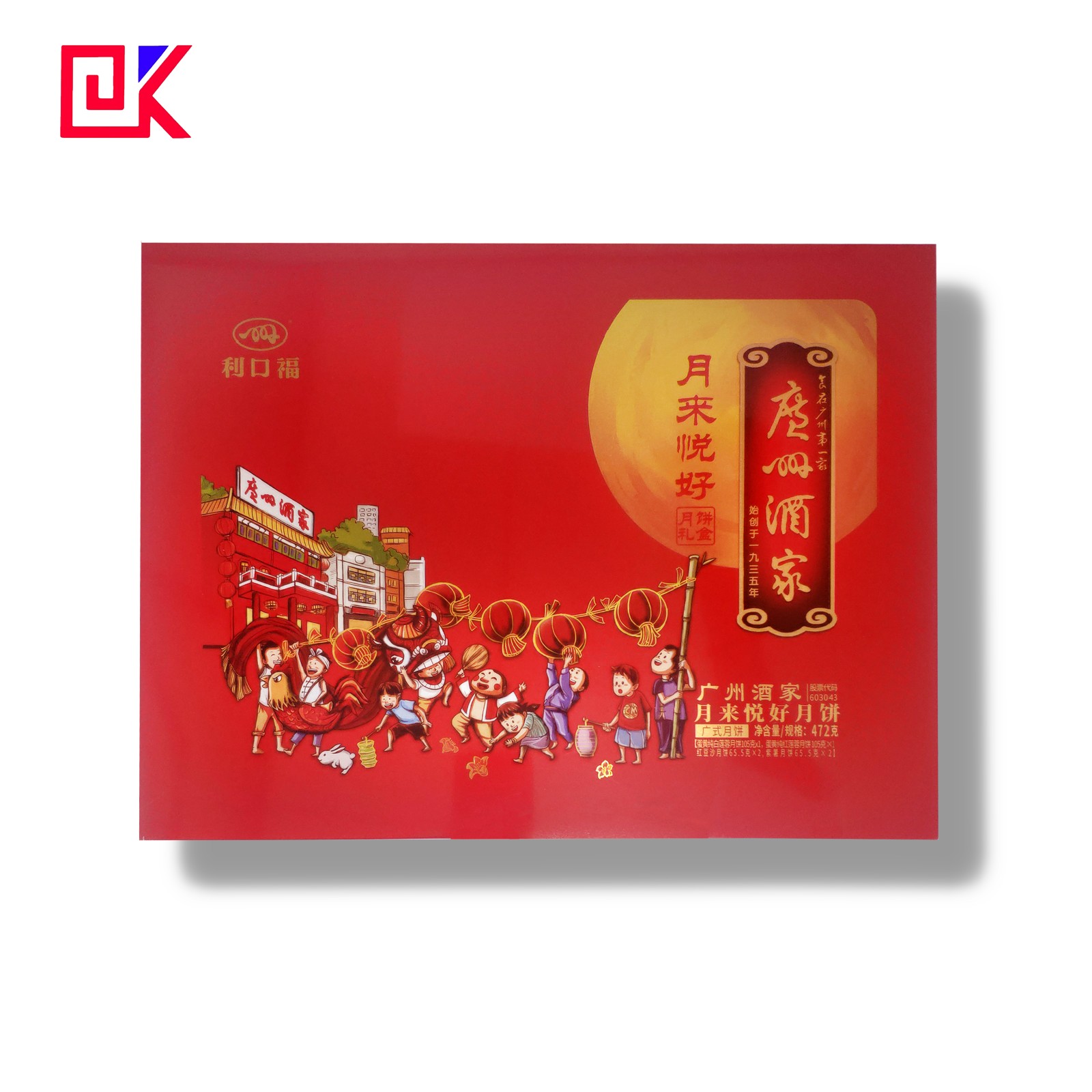

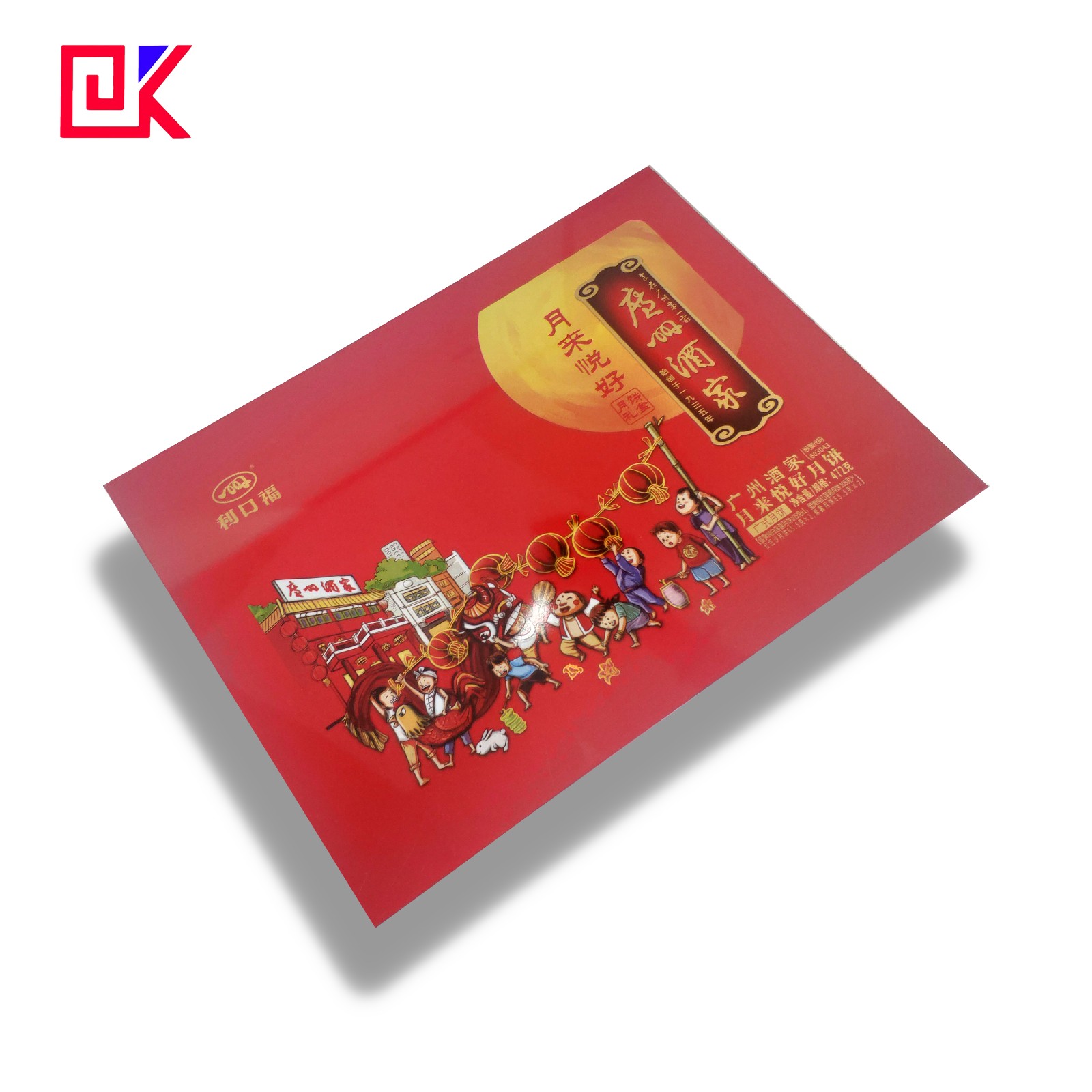

Product Show

Printing Detail

Outside Printing

Internal Coating

All of our products support customization, if you need please feel free to contact us.

Tin coating on tinplate:

Tinplate Status | Coating Status | Former Coat | Coating W. Code | Normal C-W | Min. Ave. C-W | Remarks |

EPT | Equally Coating (E) | 10# | 1.1/1.1 | 1.1/1.1 | 0.9/0.9 | All specifications |

20# | 2.2/2.2 | 2.2/2.2 | 1.8/1.8 | |||

25# | 2.8/2.8 | 2.8/2.8 | 2.5/2.5 | |||

50# | 5.6/5.6 | 5.6/5.6 | 5.2/5.2 | |||

75# | 8.4/8.4 | 8.4/8.4 | 7.8/7.8 | |||

100# | 11.2/11.2 | 11.2/11.2 | 10.1/10.1 | |||

Classified Coat (D/A) | 25#/10# | 2.8/1.1 | 2.8/1.1 | 2.5/0.9 | ||

50#/10# | 5.6/1.1 | 5.6/1.1 | 5.2/0.9 | |||

50#/25# | 5.6/2.8 | 5.6/2.8 | 5.2/2.5 | |||

75#/25# | 8.4/2.8 | 8.4/2.8 | 7.8/2.5 | |||

75#/50# | 8.4/5.6 | 8.4/5.6 | 7.8/5.2 | |||

100#/25# | 11.2/2.8 | 11.2/2.8 | 10.1/2.5 | |||

100#/50# | 11.2/5.6 | 11.2/5.6 | 10.1/5.2 | |||

100#/75# | 11.2/8.4 | 11.2/8.4 | 10.1/7.8 |

What is CMYK printing tin plate?

Tinplate, also known as tin-plated iron, is an alias for electroplated tin steel sheet. Tinplate printing also uses the physical properties of water and ink repellency. With the help of printing pressure, the tinplate is pressed onto the tinplate by a blanket, which belongs to the principle of offset printing.

Normal four-color printing: Refers to the printing process that uses the three primary colors of yellow, magenta and cyan and black ink to reproduce the colors of the color original. And because cyan and blue are similar, the four colors have a popular saying in many places: black, red, blue, and yellow. The four-color printing is also called CMYK printing method.

Characteristics of CMYK printing tin plate:

The raw and auxiliary materials for tinplate printing mainly include the following:tin plate,tinplate coating,tinplate printing ink, PS plate, fountain solution, blanket, etc.tinplate printing is different from other kinds of printing, the key important three kinds of raw material is:tin plate,tinplate coating,tinplate printing ink.

1. How to choose a tinplate

When selecting tinplate, the requirements of the type of product (beverage can,aerosol can, milk powder can, tin gifts, gifts made of tin, battery iron, etc.) and the parts of the product (bottom cover, top cover, can body, etc.) should be considered at the same time ,please refer to Table for the selection method of tinplate.

name | parts | Thickness(mm) | hardness | Tin coating | |

Beverage can | Alu EOE cover | 0.24/0.25/0.26 | H19/H48/H39 | -- | |

Bottom cover | 0.20/0.21 | T3/T4 | #25/25 | ||

Can body | 0/19/0.20/0.21 | T4 | #10/10,25#/25 | ||

aerosol can | 3-piece high pressure aerosol can | Top cover | 0.35/0.40 | T4 | 25#/50 |

Bottom cover | 0.40 | T4 | 25#/50 | ||

Can body | 0.20/0.23 | T4 | 25#/25 | ||

3-piece normal aerosol can | Top cover | 0.31/0.32(D200/201/202 | T2/T3 | 25#/50 | |

0.32(D203.5/206/205) | T3/T4 | 25#/50 | |||

0.34/0.35(D207.5/211/209 | T3/T4 | 25#/50 | |||

Bottom cover | 0.28/0.30(D200/201/202 | T3/T4 | 25#/50 | ||

0.32(D203.5/206/205) | T4 | 25#/50 | |||

0.32(D207.5/211/209 | T4 | 25#/50 | |||

Can body | 0.19/0.20 | T3/T4 | #25/25 | ||

milk powder can | Top cover | 0.23 | T3/T4 | #25/25 | |

Bottom cover | 0.23 | T4 CA | #25/25 | ||

Can body | 0.23 | T4 CA | #25/25 | ||

battery | 0.18/0.19/0.20 | T2.5 | #10/25 | ||

2. How to choose tin plate printing ink

When choosing tin plate printing ink, it is crucial to consider the specific product requirements of your enterprise, such as whether the cans are for sprays, food, or deep-drawn applications. The selection of the appropriate ink is fundamental to ensuring the quality and safety of the final product. Below are the key factors that should be taken into account:

Harmful Substance Testing: The chosen ink must come with a test report from SGS or a similar testing agency, certifying that the levels of heavy metals and other harmful chemicals do not exceed safety standards.

Material Safety Data Sheet (MSDS): Ensure the ink is accompanied by an MSDS, which provides comprehensive information on the hazardous properties, safe handling, and emergency response measures related to the chemicals in the ink.

Heat Resistance: The ink must withstand the heat curing process, typically between 150°C to 205°C, without color degradation. This is crucial as the ink forms a hardened film through this heating process, ensuring durability.

Solvent Resistance: The ink should resist solvents used in varnishing processes, such as benzene, ester, alcohol, and ketone, to prevent issues like pattern bleeding or discoloration.

Boiling Water & High-Temperature Resistance: For food cans, the ink must endure sterilization processes involving exposure to boiling water and high-temperature steam (100°C - 120°C) without losing color or gloss.

Processing Resistance: The ink must maintain adhesion, flexibility, and resistance to wear during mechanical processing, ensuring it does not peel or wear off.

High Viscosity: Due to the non-permeable surface of tinplate, the ink should have high viscosity to prevent dot gain during printing.

Transparency: For designs where the natural color of the tinplate is part of the packaging aesthetic, such as in Red Bull beverage cans, the ink must have high transparency to allow the tinplate’s tint to show through.

These considerations ensure that the selected tin plate printing ink not only meets safety and regulatory standards but also delivers superior performance and durability in the final product.

3. How to choose tinplate coating

a. Base Coating

Adhesion: Must adhere well to tinplate and printing ink.

Thermosetting and Flexibility: Should withstand heating without losing flexibility.

Low Yellowing: Light in color with minimal yellowing after drying.

Solvent Evaporation: Moderate evaporation for even coating.

Water Resistance: Should resist water well.

Non-toxic: Must be safe, odorless, and not affect contents.

Whiteness and Saturation: High whiteness, no yellowing during processing.

Adhesion and Flexibility: Strong adhesion and flexibility for durability.

Smoothness and Gloss: Smooth film with good gloss.

Solvent Resistance: Must resist varnish solvents.

Impact Strength: Should withstand physical impacts.

c. Varnish

Gloss and Smoothness: Provides gloss and a smooth surface.

Heat Resistance: Maintains color and doesn’t yellow after baking.

Durability: Offers surface hardness and wear resistance.

Flexibility: Compatible with white coating and printing inks.

Sterilization Resistance: For food cans, must withstand steam sterilization.