11-27/2024

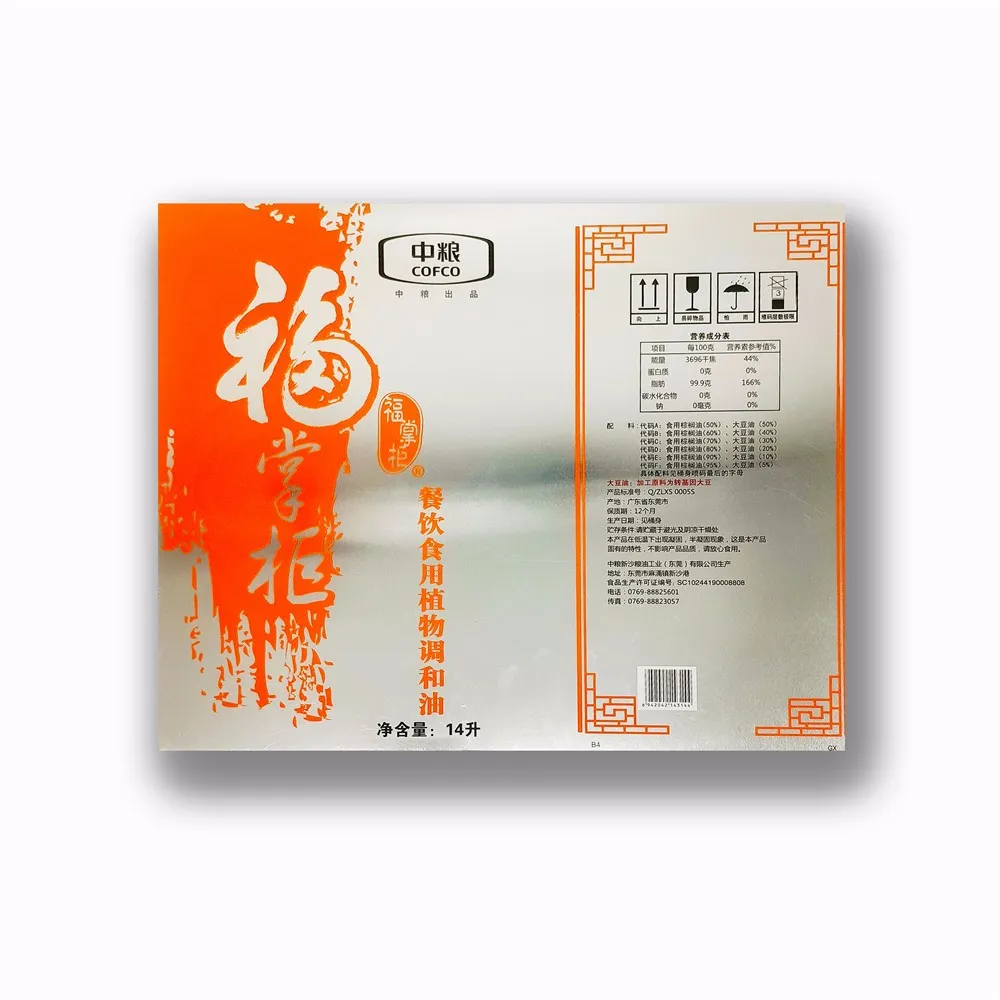

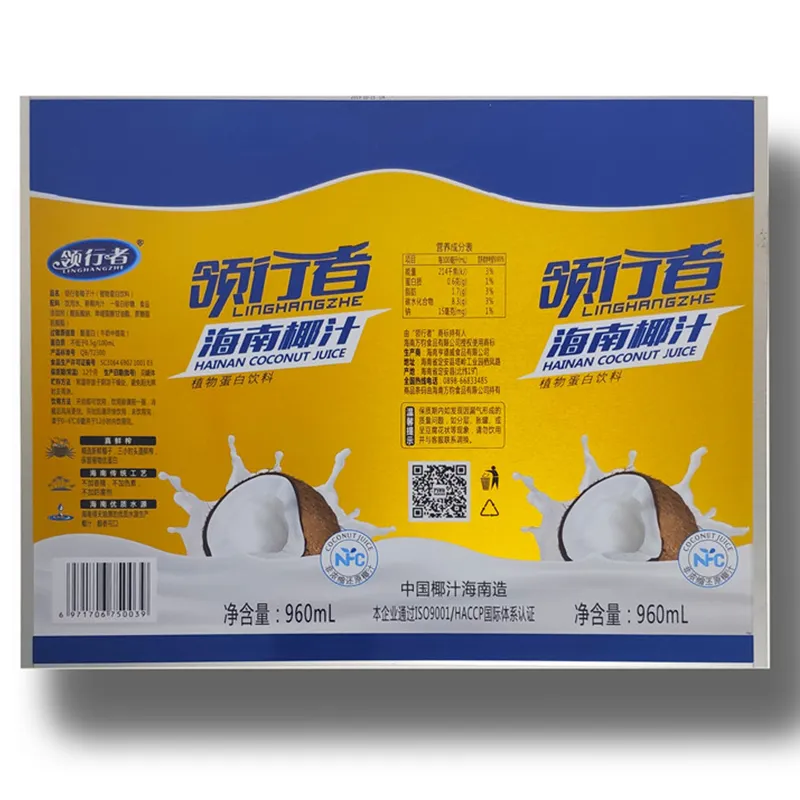

Epoxy resin coating can not only prevent metal from direct contact with food, avoid metal corrosion or contamination of food, but also extend the shelf life of food. Therefore, the inner wall coating of many food and beverage cans contains BPA.