In recent years, the safety of food packaging cans has attracted widespread attention, especially for the composition and safety of metal packaging cans. The tin plating process is widely used in food packaging, but some people question its safety and believe that the tin plating layer may pose a risk to health. This article will explore the tin plating process of food packaging cans in depth and whether this process will have an impact on human health.

What is the tin plating process of food packaging cans?

1. What is the tin plating process?

Tin plating is a process of plating a thin layer of tin on the surface of metal, usually used for surface treatment of steel materials. The commonly used material for food packaging cans is tinplate, also known as tin-plated iron, that is, a layer of tin is plated on a thin steel or iron plate. The purpose of tin plating is to increase the corrosion resistance and protection of the metal surface, so that the food is not easily contaminated or corroded by the outside world during storage and transportation, thereby extending the shelf life.

2. Why use tin-plated iron to make food packaging cans?

The tin plating process is widely used in the manufacture of food packaging cans because tin has good antioxidant properties and relatively stable chemical properties. It does not react like other metals when it encounters water or acid, and can provide stronger corrosion resistance for packaging cans. At the same time, the surface of tin is smooth, odorless, and non-toxic, and will not affect the taste and quality of the food inside the package. Therefore, tin-plated iron is widely used in food packaging containers such as food cans, beverage cans, and candy boxes.

Will the tin coating dissolve or penetrate into food?

1. Will the tin coating dissolve?

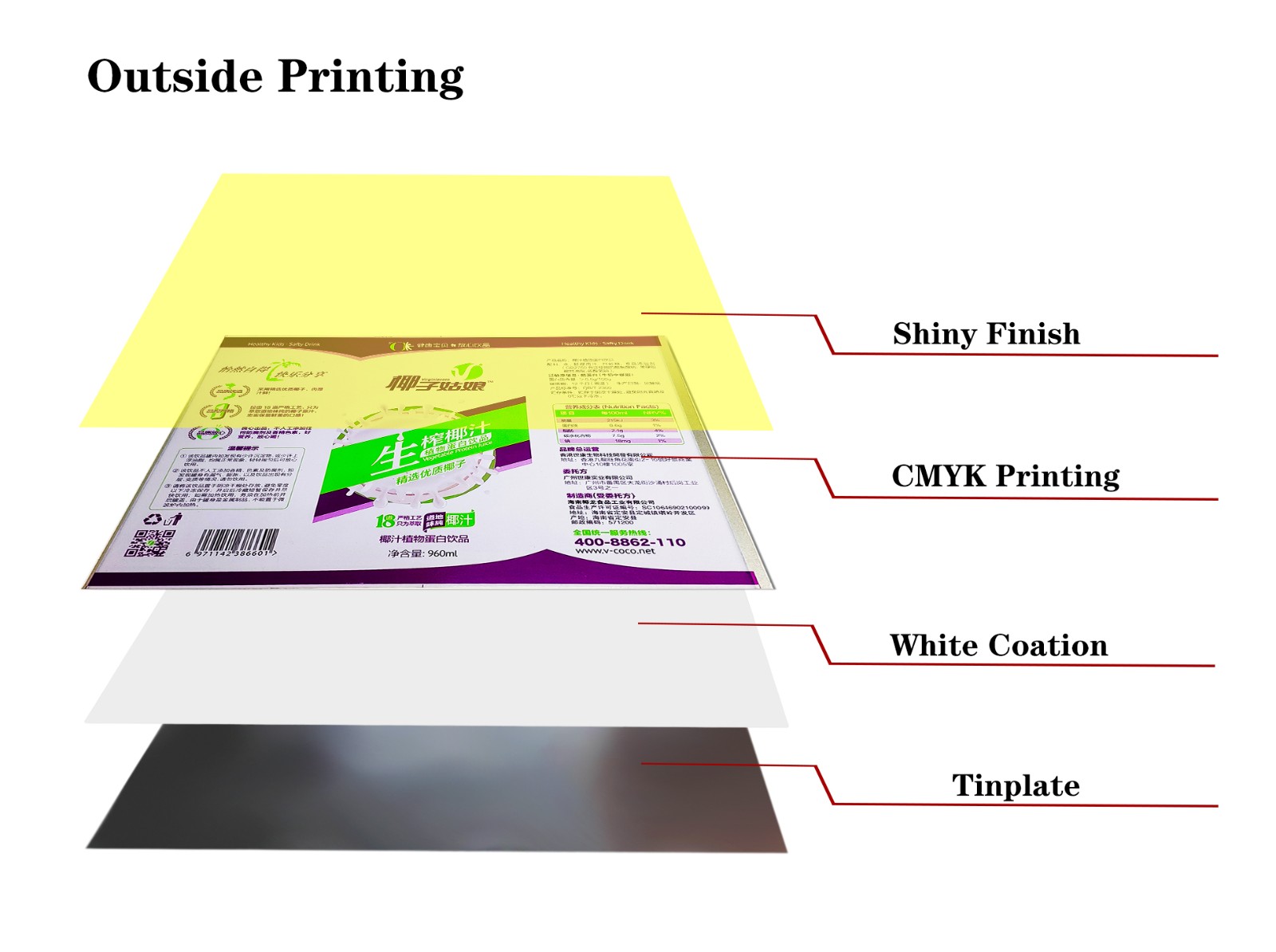

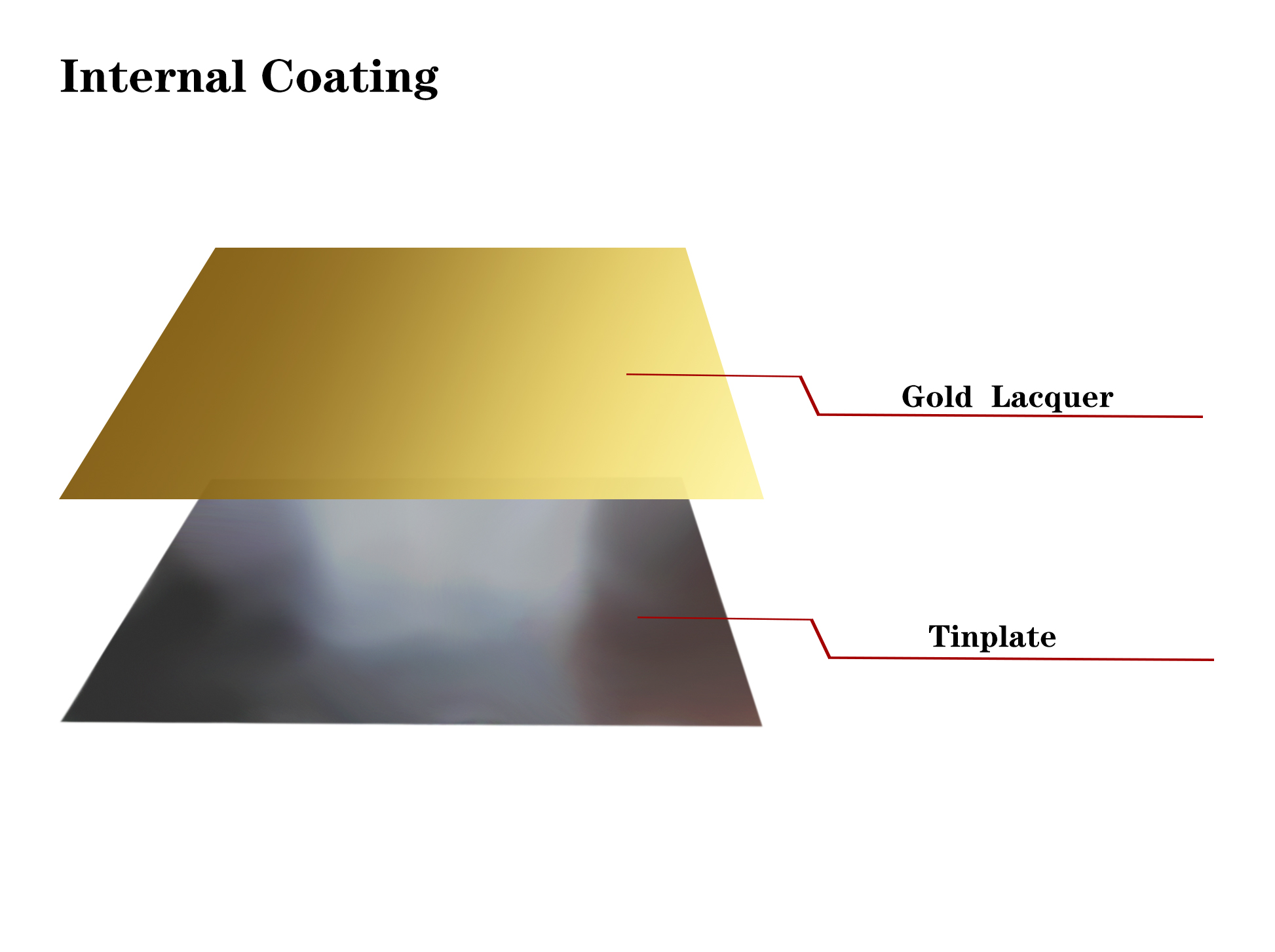

Tin has a certain stability, but it is not completely insoluble. Under some strong acidic or high temperature conditions, the tin coating may slowly dissolve and enter the food over time. However, in order to reduce the occurrence of this situation, the inner wall of the food can usually has a protective coating, that is, a layer of non-toxic and harmless resin or plastic coating certified for food safety. This coating acts as an isolation, not only protecting the tin layer from direct contact with food, but also further preventing the tin layer from being dissolved under certain specific conditions.

2. Will the tin coating react with acidic food?

Tin is relatively stable in a neutral or weakly acidic environment and is difficult to react chemically. However, when encountering highly acidic foods, such as some canned foods containing acetic acid, the tin coating may be slightly corroded by the acidic components. This corrosion process is very slow and does not cause significant tin migration risk under normal use conditions. Therefore, for acidic foods, food packaging can manufacturers usually choose a more solid inner wall coating to protect them to ensure the safety of food packaging cans.

Is the presence of tin in food packaging cans harmful to the human body?

1. What effect does tin intake have on the human body?

Tin itself is a low-toxic metal. A small amount of tin is harmless to the human body, and the human body can even metabolize a very small amount of tin. The International Food Codex Commission (CODEX) and the World Health Organization (WHO) have strictly controlled and limited the migration of tin in food to ensure that tin in food packaging does not pose a threat to human health. According to relevant research, the tin content in food packaging cans is far lower than this standard, so there is no need to worry too much about the impact of tin in food cans on health.

2. Are there any cases of tin poisoning?

Tin poisoning is an extremely rare condition that usually only occurs when a large amount of tin is ingested or when exposed to a high tin environment for a long time. Under normal circumstances, the trace amount of tin ingested by the human body will be excreted through urine within a few hours to a few days. Therefore, as long as the tin-plated cans meet the food safety standards, they will not cause tin poisoning. Safety test data show that the migration of tin in food packaging cans that are in daily contact is extremely low, which meets the international safety standards.

Are there any toxic residues in the production process of tin-plated iron?

1. Will the chemicals used in the tin-plating process remain in the can?

Some chemical agents are indeed used in the tin-plating process to assist the formation of the tin-plating layer, but these chemicals will be thoroughly cleaned and treated after the tin-plating is completed to ensure that they will not remain in the finished cans. These process measures not only meet the requirements of food safety regulations, but also carry out strict quality monitoring to ensure the safety and hygiene of each link. The final finished cans will undergo multiple tests before leaving the factory, including solvent residue and heavy metal migration tests, to ensure their safety.

2. How to ensure the safety of tin-plated iron cans after production?

In the production of food packaging cans, a coating link is usually added. This coating is a further protection for the tin layer, and the coating materials all meet the safety standards for food contact materials. After the production process is completed, the can body will undergo food grade testing and packaging safety testing to ensure that the finished can does not pose a threat to food safety. This protective coating can effectively block the direct contact between the tin layer and food, thereby avoiding the risk of tin migration.

Do tin-plated food packaging cans meet international food safety standards?

1. What are the safety standards for tin-plated food cans?

The production and use of tin cans are strictly regulated by a number of international food safety standards. Institutions such as the European Food Safety Authority (EFSA), the U.S. Food and Drug Administration (FDA) and the China Food and Drug Administration (CFDA) have strict regulations on the migration of heavy metals in food packaging materials. The safety testing of food packaging cans needs to meet various heavy metal migration standards, including the migration limit of tin, to ensure the health and safety of consumers when eating canned food.

2. How is tin-plated food cans regulated worldwide?

Globally, countries have strict supervision over food packaging materials. Tin-plated food packaging cans are subject to multiple tests at the export and import stages, including metal migration tests, microbial tests, etc. Such testing standards and processes ensure the food safety of consumers in different countries. Under the multi-level testing standards and technical control, the safety of tin-plated food packaging cans has been effectively guaranteed worldwide.

How do consumers correctly choose and use tin-plated food packaging cans?

1. How to judge the safety of canned food?

When purchasing canned food, consumers should choose products from regular manufacturers, which usually undergo multiple safety tests. Generally speaking, the canned packaging materials produced by regular brands and manufacturers are of stable quality, meet food grade standards, and the amount of tin migration is also within the safe range. In addition, consumers can also check the expiration date of the food packaging cans and whether there are dents, corrosion, etc., which may affect the safety of food.

2. How to store tin-plated cans at home?

When storing canned food at home, try to keep the cans in a cool and dry environment, avoid direct sunlight or high temperature environment, so as to extend the shelf life of the cans and maintain the stability of the tin coating. After opening, it is recommended to put uneaten canned food in a sealed container and refrigerate it to prevent the contents from contacting with air and causing corruption. Correct storage methods can effectively reduce tin migration and extend the shelf life of canned foods.