Specification of CMYK Printing Tin Sheet For 5 L Olive Oil Can:

Product name | CMYK Printing Tin Sheet For 5 L Olive Oil Can |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T2,T3 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.23~0.25mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

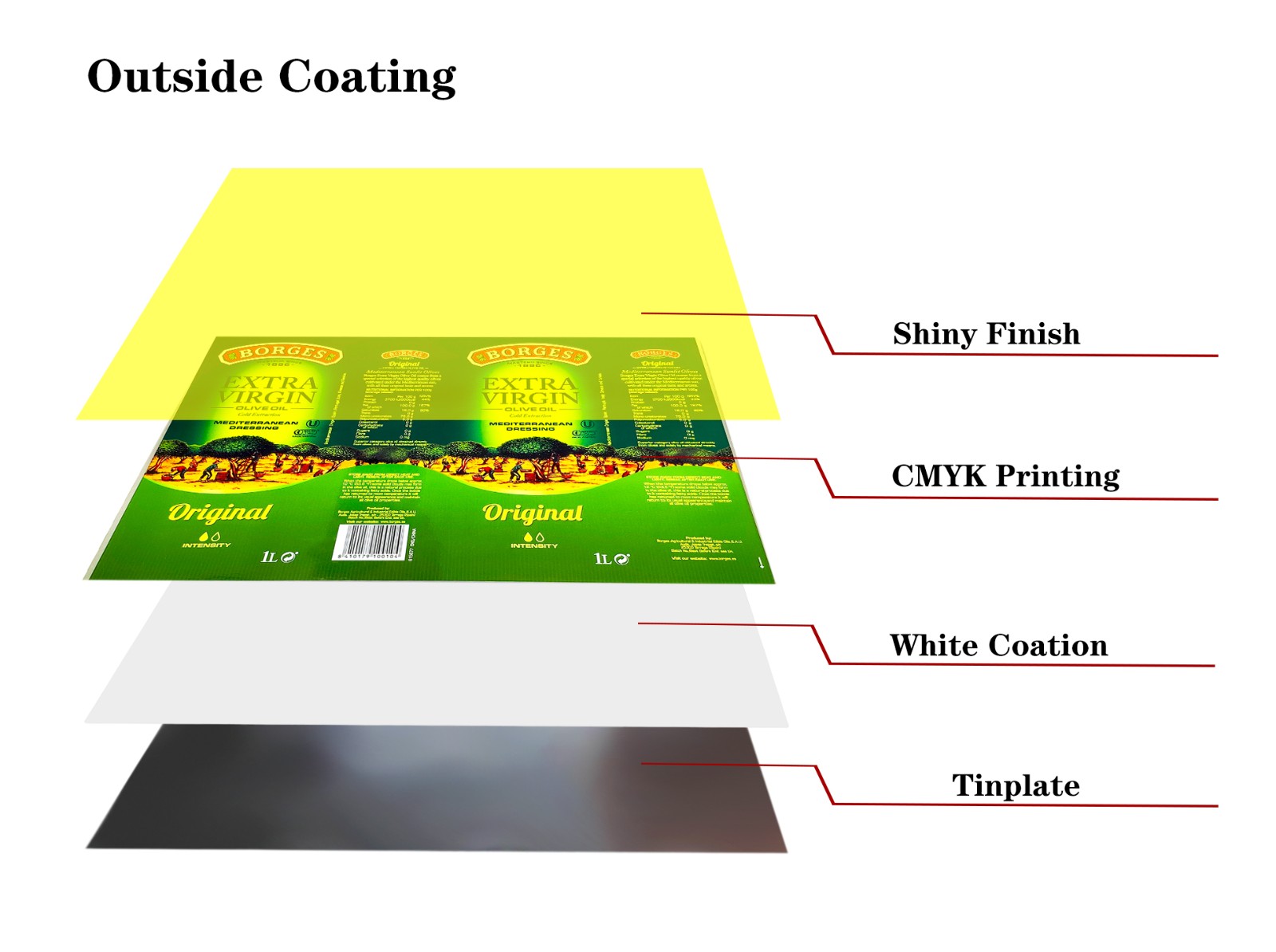

Internal coating | White coation or Gold lacquer |

Outside printing | White coation+CMYK Printing+transparency lacquer |

Application | For any packing Box,Tin, Can, Bucket, etc(Food,olive oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

Tin coating on tinplate:

Classification | Designation of | Nominal tin (g/m2) | Min average (g/m2) | Remark |

Equai tin coating(E) | 1.1/1.1 | 1.1/1.1 | 1.8 | All specification |

2.2/2.2 | 2.2/2.2 | 4.0 | All specification | |

2.8/2.8 | 2.8/2.8 | 5.0 | All specification | |

5.6/5.6 | 5.6/5.6 | 10.5 | All specification | |

classification | 2.2/1.1 | 2.2/1.1 | 2.0/0.9 | All specification |

2.8/1.1 | 2.8/1.1 | 2.25/0.9 | All specification | |

5.6/1.1 | 5.6/1.1 | 5.05/0.9 | All specification | |

2.8/2.2 | 2.8/2.2 | 2.25/2.0 | All specification | |

5.6/2.2 | 5.6/2.2 | 5.05/2.0 | All specification | |

5.6/2.8 | 5.6/2.8 | 5.05/2.25 | All specification |

Surface state of tinplate:

Marks | Suface state | Characteristics |

B | Bright rough | Glazed surface obtained after melting treatment of electroninned smooth raw material strip featuring certain oriented rubstone figure. |

R | Stone rough | Glazed surface obtained after melting treatment of electroninned raw material strip featuring certain oriented rubstone figure. |

S | Silver rough | Glazed surface obtained after melting treatment of electroninned raw material strip with rough matt surface. |

Cerfication: Approved by the ISO 9001

What rules need to be followed for CMYK printing color sequence?

In multi-color overprinting, the process of overlapping overprints in a certain order using a single color as a unit, and finally restoring it to the original, is called the ink overprinting order, or color order for short.

The arrangement of color sequence is subject to various conditions. In order to obtain a good reproduction effect, the following basic principles should generally be followed:

①: Arrange the color sequence according to the lightness of the three primary colors: first print the dark color, then print the bright color.

②: According to the lightness and hiding power of the three primary color inks, the color sequence is arranged. The ink with poor transparency is printed first, and the ink with strong transparency is printed after.

③: According to the size of the dot area, the color is generally printed before the dot area is small, and the dot is printed after the large area.

④: arrange the color sequence according to the characteristics of the original: graphics with a warm tone are printed in black, cyan, and magenta, and yellow; graphics with a cool tone are printed in magenta, and then green.

⑤: Sort the color sequence according to the model: Generally, the color sequence of single-color or two-color offset presses is that the light and dark inks alternate with each other. The color sequence of four-color offset presses is generally black, magenta, cyan, yellow, or black, cyan, magenta, and yellow.

⑥: Arrange the color sequence according to the nature of the paper: smooth, compact paper is printed with dark color first, followed by bright color; thick and loose paper is printed with bright color first, and then dark color.

⑦: Sort the color sequence according to the dryness of the ink: the slow-drying ink is printed first, and the fast-drying ink is printed after.

⑧: The color order is arranged according to the flat screen and the field: the flat screen graphics are printed first, and the solid structure is printed later.

⑨: arrange the color sequence according to light ink and dark ink: dark ink is printed first, light or spot color ink is printed after.

It is convenient to arrange the color sequence according to the rules of fitting and color changing: the main color or strong color fitting should be as close to one another as possible, and cannot be separated by anyone. In addition, the color sequence must take into account the convenience of color changing, otherwise it will increase the auxiliary time. . In short, the arrangement of color sequence is a very important and complex issue. It must be analyzed in detail and must not be carried out blindly.

FAQ:

1). What is minimum order quantity?

A: The MOQ is about 2 tons for each size, but it is flexible, we would consider customer's requirement.

2). What kind of terms of payment?

A: Usually payment terms,L/C,T/T,etc.

3). Could offer us samples?

A:Yes, we can offer the samples within two working days, but if the samples are customized or special coatings, it may take more time.

4). Can you do Customization & Reproduction if I provide a sample?

A:Yes, we do Customization & Reproduction service.

5). Is the packaging safe and arriving in good conditions?

A: Yes, safe Packing guarantee , all the products will arrive at your door under good conditions.

We response to problem of shipping if there unfortunately is.

6). How long does it usually take to deliver the product?

A: We will make the shipment to you immediately. It will take about 20 to 40 days arrive worldwide. It depends on the order quantities and specifications.