Specification for Tin Containers Food Grade:

Product name | CMYK Printing Tin Containers Food Grade |

Material | Prime Tinplate sheet, tin coil, tin steel |

Steel type | MR grade for food tin Containers |

Tin coating | 2.8g/㎡ |

Temper Grade | T1~DR10 |

Annealing | CA,BA |

Thickness | 0.18~0.30mm |

Normal width | 508~960mm |

Normal length | 712~1145mm |

Internal coating | Gold lacquer/aluminum paste/transperancy lacquer |

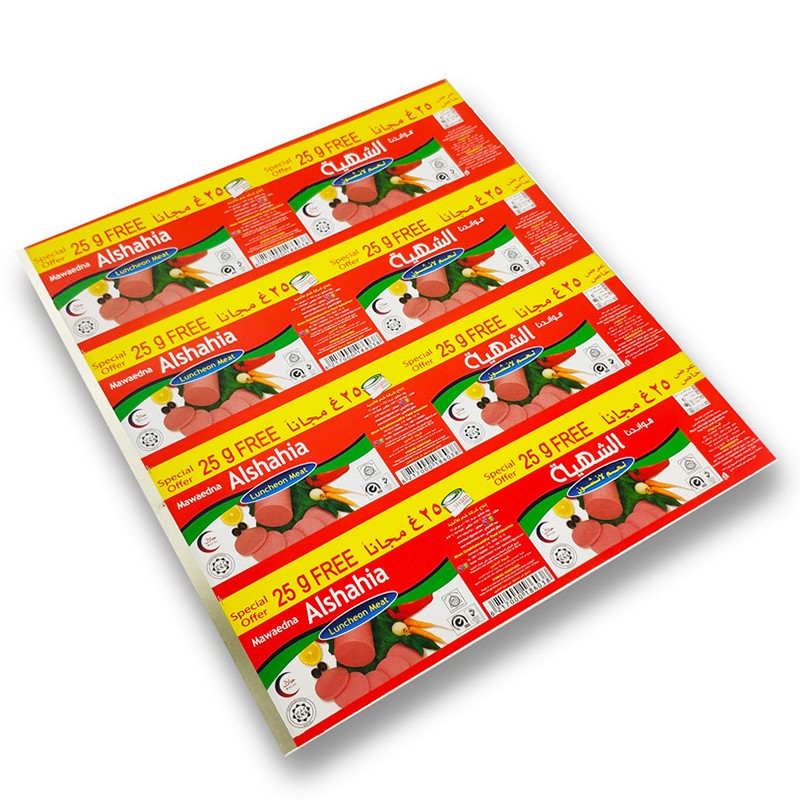

Outside printing | White coation+CMYK Printing+glossy for matte finish |

Color | Red, Blue, White, Yellow, Green, Pink,Grey,Gold,Black etc all kinds of Color |

Printed Tinplate Sheet used for | Food tin metal cans like: Tomato paste tin can , Milk powder tin can, baking power tin can, Cheese tin can,Twsit off caps , Beer caps, Tuna cans, Juice cans, Cookie cans, Hot dog cans, Coffee cans, Nuts, Oil cans etc all kinds of Food tin metal cans. |

Printing tinplate sheets MOQ | 2 tons per size |

Printing capacity | 4000 tons per Month |

Printing delivery time | 15~20 days |

What is CMYK Printing tin ?

The tinplate four-color printing is a printing process in which the colors of the design draft are superimposed by the four colors of CMYK, and the spot colors are copied with a single ink by using C, M, Y, and K inks. From the perspective of printing effect, the spot color printing color is more full. From the perspective of printing cost, spot color printing is higher than four-color printing.

Four colors are used in ordinary printing. The four basic primary colors are blue, red, yellow, and black. So in general, the screen display may exceed the colors that can be printed. When making prints, pay attention that spot colors are mainly used for some specific trademark colors. So when adding a spot color swatch such as PANTONE color when printing, 12 basic colors of RGB and CMYK grades must be matched.

The four-color printing process of the packaging iron box has some errors in printing errors and display errors. The spot color printing errors are small, and even the display errors are avoided. When customers choose products, dekai company will use a more reasonable printing process and multiple one-stop tin box packaging solutions based on the printing information provided by the customer.

Production capablity:

Our tinplate is coated and printed using equipment from the Japan company “FUJI“:there are 5 production lines for tin steel coating and printing, it has an efficiency of 6,000 plates per hour.Our tin steel printing has resolution of 170 LPI

1)Our company have two factories:one is tinplate coating and printing, and the other is tin can making , can supply one-stop service from plain tinplate, coated tinplate ,printed tinplate ,lacquered tinplate till the final tin cans.

2)Smooth production ability 4,000tons each month .

3)OEM/ODM , Free of charges of Logo design and printing on your goods .

Quality assurance:

1)The Right Material, First Time: Quality is the hallmark of our reputation.

2)Strict quality control,ensure any product satisfied with yours application .

3)Quality Control:

Material Inspection → Drawing and Samples` → Inspection →Correction of Machine and Equipment → Trial production → Finished Production Testing →The Third inspect department