Specification of Cmyk Offset Printed Tin Sheet For Paint Can:

Product name | Cmyk Offset Printed Tin Sheet For Paint Can |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.20~0.38mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

Internal coating | Gold oil or tansparency lacquer |

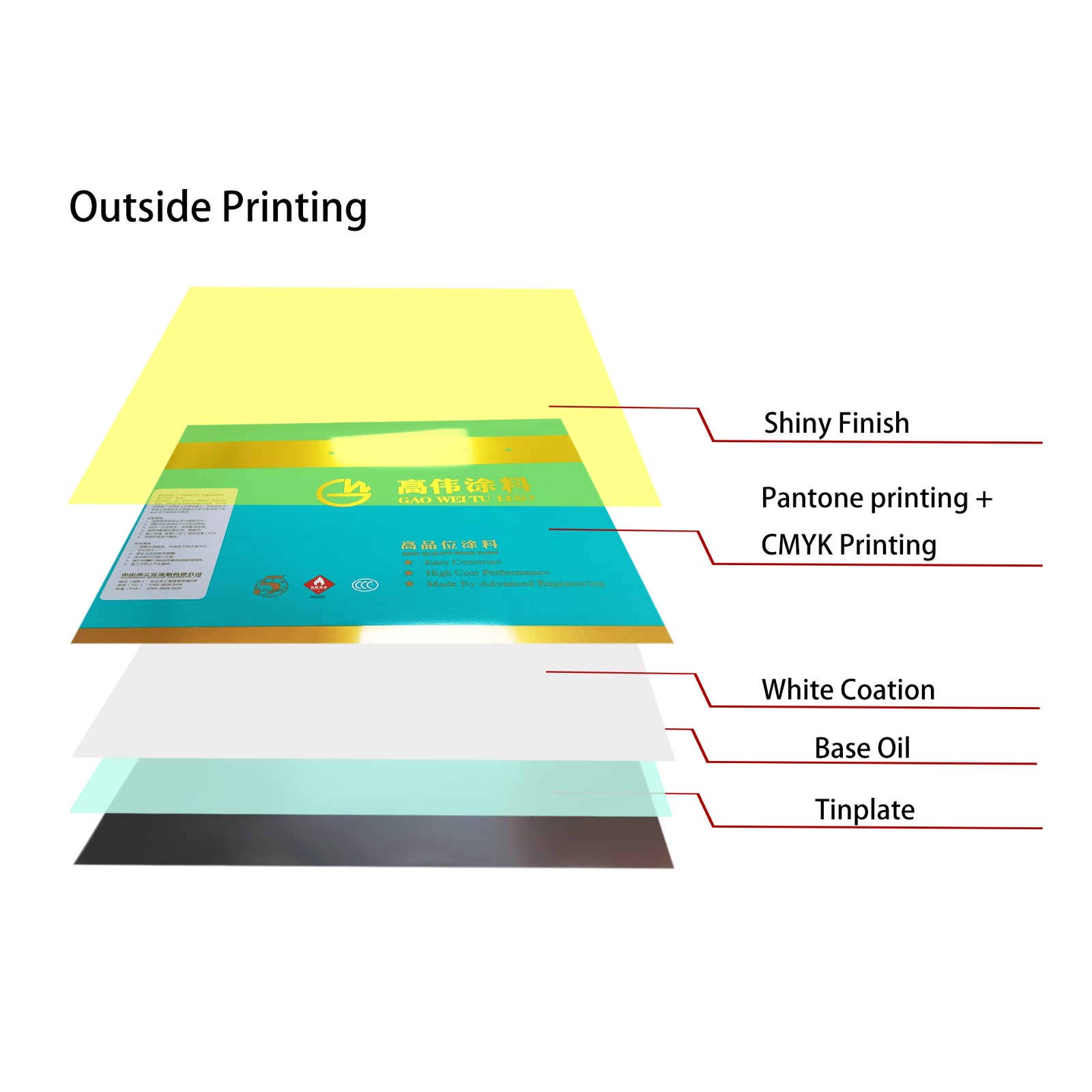

Outside printing | White coation+CMYK Printing+Green+Shiny finish |

Printed Tinplate Sheet used for | For any packing Box, Can, Bucket, etc(Paint,Food, oil, medicines, cosmetics, perfume,toys, chemicals, aerosol, printed tin containers etc.) |

Printing tinplate sheets MOQ | 2 tons per size |

Printing capacity | 4000 tons per Month |

Printing Tinplate

Tinplate For Chemical Can

Printing Detail

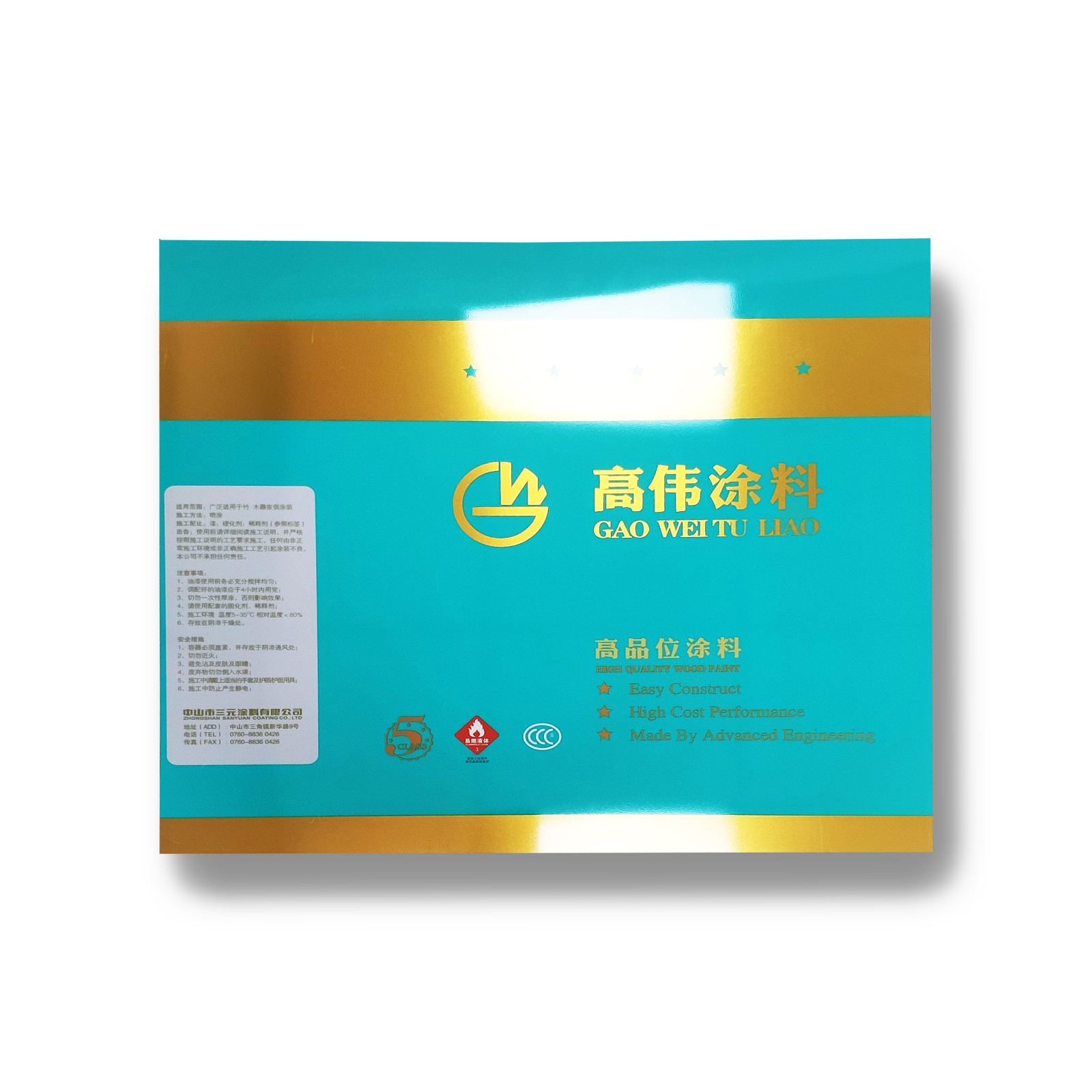

Product Show

Outside Printing

Our advantage:

Whether you need printed tinplate ,tin cans, complex miscellaneous metals, or stock steel material you will get:

1. The Right Material, First Time: Quality is the hallmark of our reputation.

2. On Time Delivery: Your projects stay on schedule.

3. Ongoing Communication: Everyone is fanatically responsive to your needs. We handle the project so there are no surprises for you.

4. ISO and SGS Certification: We help you meet your goals plus the goals of your owners/customers.

Why you choose us:

1. Competitive price and high quality from our own factory.

2. Our company have two factories:one is tinplate coating and printing, and the other is tin can making , can supply one-stop service from plain tinplate, coated tinplate ,printed tinplate ,lacquered tinplate till the final tin cans.

3. Approved by the ISO 9001

4. Smooth production ability 4,000tons each month .

5. Strict quality control , ensure any product satisfied with yours application

6. OEM/ODM , Free of charges of Logo design and printing on your goods .

How to distinguish spot colors printing and CMYK printing?

There are two types of printing for offset printed tin: spot colors printing and CMYK printing(also called four colors printing). How should we distinguish them?

1. CMYK printing

CMYK printing is also called four-color printing ,tin sheet is printed with four basic inks, blue, red, yellow, and black, using offset printing (like paper printing). Many different patterns can be printed. Careful observation with a magnifying glass can be seen on the printing. There are halftone dots (like the TV display, there are pixels, and the effect is enlarged by N times), so the four-color printing is actually a combination of halftone dots.

2. Spot color printing:

Spot color printing is compared with the color on the color card, and the ink is adjusted first, and then printed, so that only one color is printed. Of course, according to the customer's product design, there can be different shapes and different patterns. Spot colors are superimposed to form different colors and patterns. Because spot colors are not hit colors, there are no dots on the surface, and they look smooth.

Some differences between CMYK printing and spot color printing:

Cost: The tinplate printing machine is a two-color machine (only two colors can be printed at a time, unlike four or six colors at a time like paper printing), so a CMYK printing requires two passes.

For spot color printing, one spot color needs to be printed twice. Two spot colors can be printed at one time. Therefore, to print two spot colors, two passes must be printed. Therefore, the printing cost of two spot colors is the same as that of a CMYK printing. The cost is the same. When you print four spot colors, the cost is the cost of two four-color printing, so the printing cost will increase.

Color: The CMYK printing is the hit color, so each time the printing ink is slightly different, the hit color will have a certain deviation (because the printing is completed by the joint operation of the machine and the human, so it is batched During the second printing, it is impossible to adjust the ink mixing ratio to be absolutely correct. Therefore, there will be some deviations between each batch of printing in the four-color printing. The printing factory promises to keep the color consistency of the sample at 90%. about.

Spot color printing is done after adjusting the ink. The ink is adjusted according to the Pantone color card, so the color difference is a little less than the four-color printing.

The surface is beautiful: Because the four-color printing is a hit color, the dots on the printing are clear when viewed with a magnifying glass. Therefore, the surface of the four-color printing is relatively rough when you look closely.

The spot color printing has no dots, and the surface is relatively smooth, which is relatively good-looking. Of course, four-color printing can print colorful patterns, while spot colors can only print a single color. So the interior products are not the same, and the choice of tin box packaging printing is also different.

How to choose four colors or spot colors:

In general, if you need to produce tin box packaging with more complicated patterns, we recommend that customers choose four-color printing. If the pattern is relatively single and the color is only one or two, the choice of spot color printing will bring more highlights. Especially for a large area of a single color, it is better to choose a spot color, so a four-color pattern design, if there is a large area of a single color, you can also choose a four-color printing plus a spot color printing, of course, In this way, the production cost of the final tin box packaging is a bit higher.

Process principle of CMYK printing sheet:

In the principle of imprint transfer, the physical properties of water and ink repel are used, and the printing plate graphic is transferred to tinplate through a blanket by means of printing pressure. Due to the special physical and chemical properties of tinplate and the reprocessing performance of tinplate printed matter, its printing process is greatly different from ordinary offset printing.tinplate printing process is as follows:

Coating before printing-Printing-coating after printed-Processing.

1. Special requirements for printing ink:

(1) Has good adhesion and mechanical properties

Because tinplate printing products are eventually made into food cans, toys, metal photo frames, and barrels ,paint cans,and cans of chemical products, they need to be cut, bent, and stretched. Therefore, printing inks are required to have good adhesion to tinplate and corresponding machinery performance. In order to improve the adhesion of the printing ink, the tinplate needs to be white-primed before printing. White is the base color of all pictures and has a very high brightness. After adding other high-energy hue, the brightness of each hue can be increased to form a Color scale.

(2) Requirements for white ink

The tinplate surface is silver-white (or yellow) with metallic luster. Before printing the color graphics, the surface needs to be printed white. Due to the limitation of the ink covering ability, it usually takes 2-3 times to print white, and its whiteness can reach 75%. Whiteness is an important indicator of the quality of printed tinplate products. Printed white ink has a good binding force with the primer, does not turn yellow after high temperature baking, and does not discolor after high temperature resistance. Applying a primer to tinplate can increase the adhesion to tinplate and have a good combination with white ink. force. The commonly used primer is epoxy-amine based, with light color, no yellowing and aging after repeated baking, good flexibility and impact resistance.

(3) Requirements for color ink

Tinplate printing color inks, in addition to having a certain degree of water resistance, also need their special requirements. As the tinplate surface does not penetrate water and solvents, it needs to be baked and dried, so its ink should be heat-curable. The pigment is required to have higher tinting strength and durability. In addition to the basic properties of general offset printing inks, iron printing inks should also have the characteristics of heat resistance, strong ink film adhesion, impact resistance, good rigidity, cooking resistance and light resistance according to the characteristics of printing iron.

(4) Drying process of ink

In the production of printing iron, the drying of the ink is a complicated physical and chemical reaction process. There are many factors that affect drying, so to control the drying speed of the ink and ensure the quality of the product, the physical and chemical mechanism in the ink drying, that is, the factors that affect the drying speed, must be mastered in order to effectively perform the fast iron printing operation. The drying speed of the ink has become the main content of the ink drying. Then, what harm is the ink drying too fast.

2. Special structure of printing equipment

Due to the different substrates, the auxiliary structure of the tinplate printer is also different from the offset printing machine. Because tinplate is insoluble in water and does not adsorb solvents, the printing ink needs to be baked at high temperature to cure the solvent volatile conjunctiva. Iron printing process equipment should be equipped with iron printing drying room. Printed iron automatic line is generally about 52 meters in length, which has the characteristics of precision and hugeness.