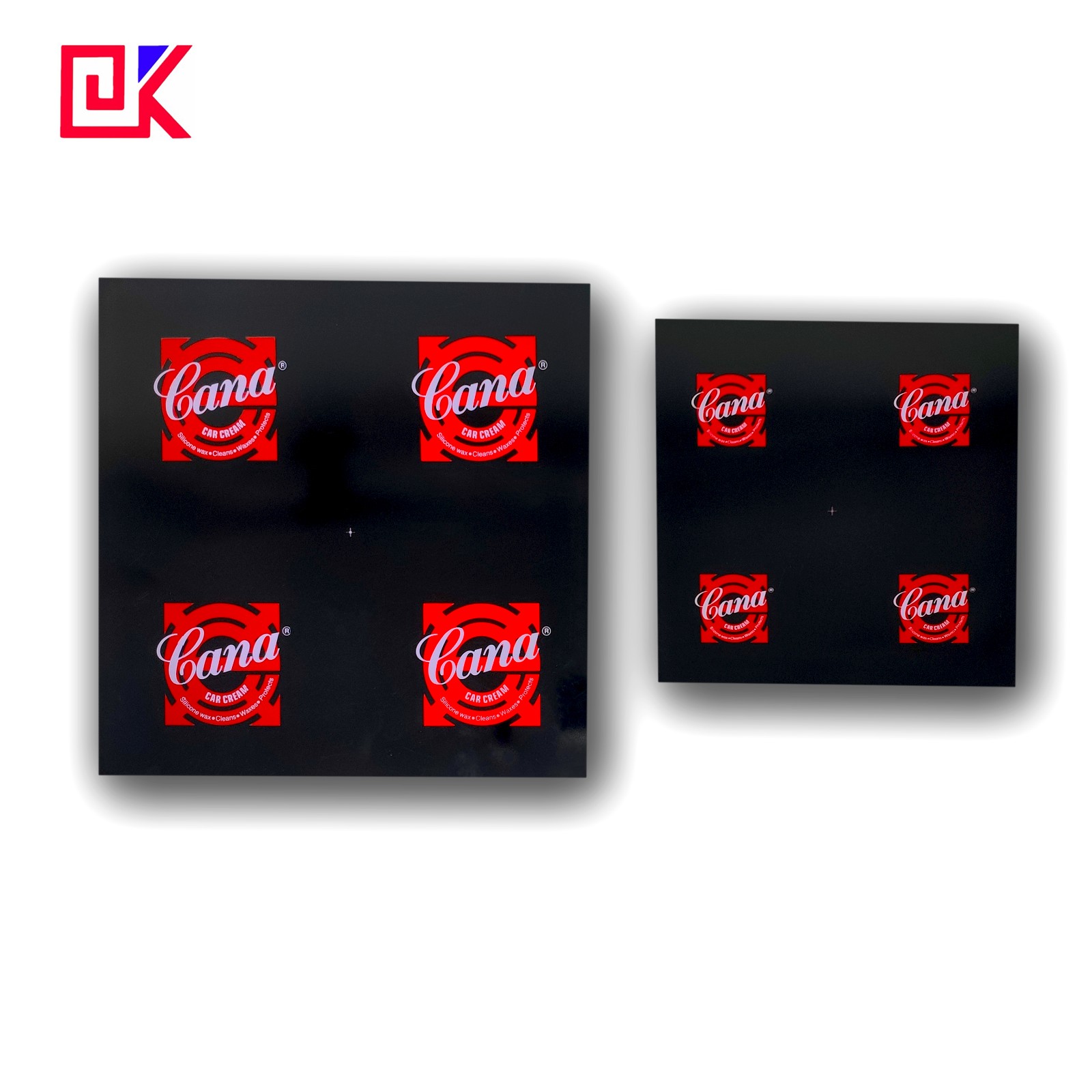

Specification of Tin Sheet Printed For Petrol Tins (petrol cans):

Product name | Tin Sheet Printed For Petrol Tins |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.21~0.28mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

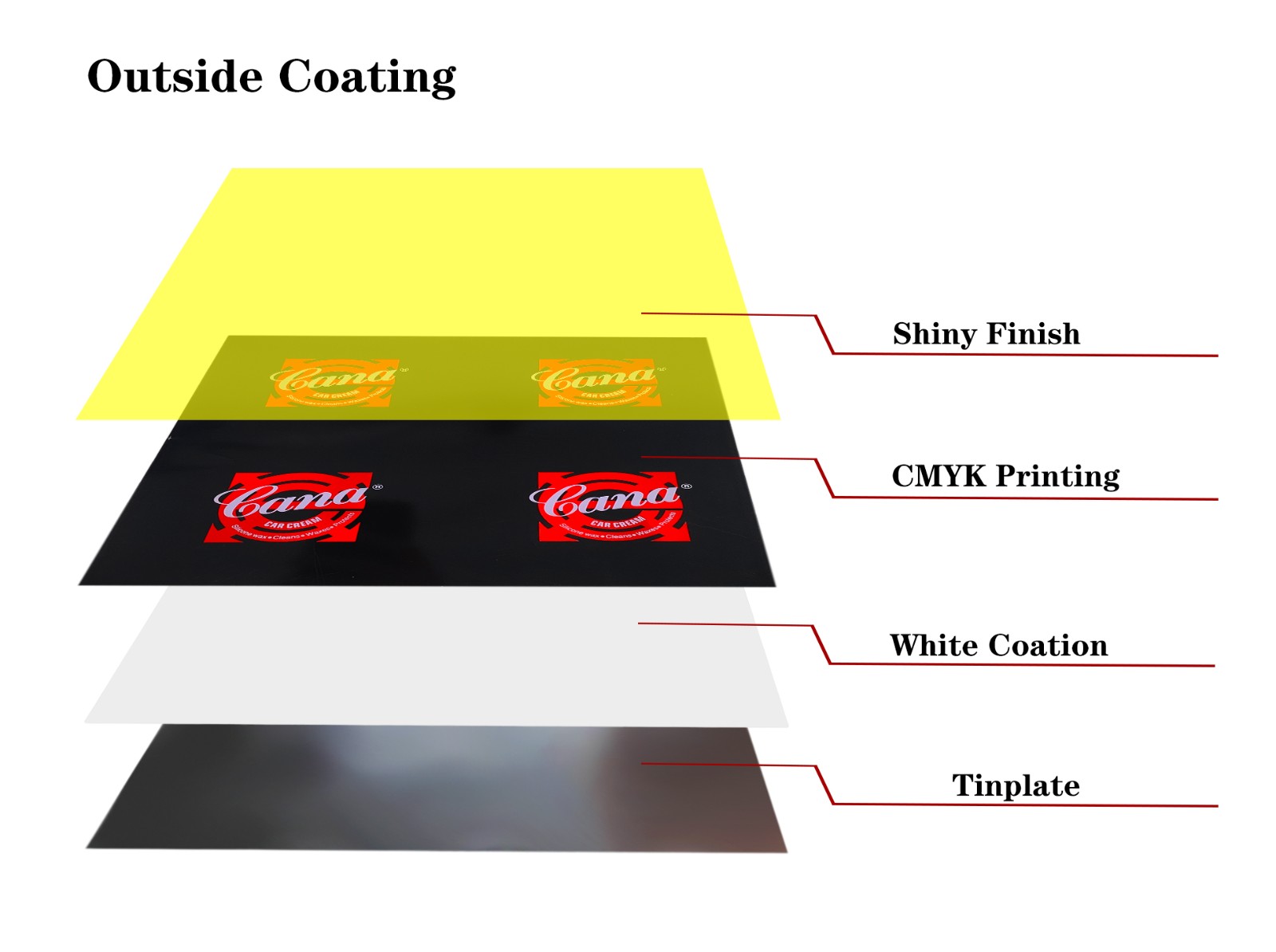

Internal coating | White coation or Gold lacquer |

Outside printing | White coation+CMYK Printing+transparency lacquer |

Application | For any packing Box, Can, Bucket, etc(Food, oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Port of Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

Tin sheet temper standard:

Code | Chineses | Japaness | American | Europen | International |

GB/T2520-2000 | JIS G3303-2002 | ASTM | DIN EN | ISO | |

T-2 | TH52+SE | T-2 | T-2(T53) | T52 | TH52+SE |

T-2.5 | TH55+SE | T-2.5 | TH55+SE | ||

T-3 | TH57+SE | T-3 | T-3(T57) | T57 | TH57+SE |

T-3.5 | |||||

T-4 | TH61+SE | T-4 | T-4(T61) | T61 | TH61+SE |

Tin coating on tin sheet:

Tinplate Status | Coating Status | Former Coat | Coating W. Code | Normal C-W | Min. Ave. C-W | Remarks |

EPT | Equally Coating (E) | 10# | 1.1/1.1 | 1.1/1.1 | 0.9/0.9 | All specifications |

20# | 2.2/2.2 | 2.2/2.2 | 1.8/1.8 | |||

25# | 2.8/2.8 | 2.8/2.8 | 2.5/2.5 | |||

50# | 5.6/5.6 | 5.6/5.6 | 5.2/5.2 | |||

75# | 8.4/8.4 | 8.4/8.4 | 7.8/7.8 | |||

100# | 11.2/11.2 | 11.2/11.2 | 10.1/10.1 | |||

Classified Coat (D/A) | 25#/10# | 2.8/1.1 | 2.8/1.1 | 2.5/0.9 | ||

50#/10# | 5.6/1.1 | 5.6/1.1 | 5.2/0.9 | |||

50#/25# | 5.6/2.8 | 5.6/2.8 | 5.2/2.5 | |||

75#/25# | 8.4/2.8 | 8.4/2.8 | 7.8/2.5 | |||

75#/50# | 8.4/5.6 | 8.4/5.6 | 7.8/5.2 | |||

100#/25# | 11.2/2.8 | 11.2/2.8 | 10.1/2.5 | |||

100#/50# | 11.2/5.6 | 11.2/5.6 | 10.1/5.2 | |||

100#/75# | 11.2/8.4 | 11.2/8.4 | 10.1/7.8 |

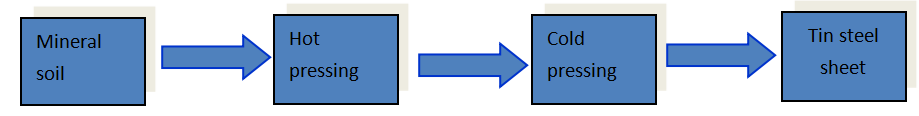

Tin metal sheet raw material comes from:

(1) Iron ore is produced in Australia and Brazil

(2) Approximately 1 ton of tin steel shet can be extracted from 1.8 ton of iron ore

Application of tin sheet printed:

tinplate printed products are widely used in different types of food, canned beverages, daily cosmetics, pharmaceuticals, and petrochemical products (gallon gas can) with their novel design and special exquisite printing effects And various packaging containers.

Tin sheet printing

(1). Selection of ink printing:

After the tinplate is processed by the inner and outer coating processes, it can be printed on the machine. Because tinplate has a smooth surface, low adhesion, and a certain degree of hardness and thickness, tinplate printing generally uses offset printing. Its printing principle: oil and water are not compatible , Dot conformation and color formation, selective adsorption. Tinplate lithography is basically the same as sheet-fed offset printing, but because of the particularity of tinplate, tinplate printing is different from ordinary offset printing in the following aspects:

① Printing ink

Ⅰ. Dryness and heat resistance of printing inks. The curing of printing inks needs to be heated and dried. Therefore, the white inks after heating must not change, do not turn yellow, the color inks do not fade, do not change color, and the varnishes do not lose light. Generally speaking, the ink needs to be fixed at 150 degrees Celsius for 10 to 12 minutes. Therefore, the heat resistance of the ink is more important.

Ⅱ. Processability, tinplate products need to go through stamping, perforating, bending, flanging, rolling and other processes, so the ink layer on the surface of tinplate should have a strong structure, and the printing ink should have good adhesion and flexibility , Surface hardness and impact strength.

② Varnish

After the tinplate printing is completed, a layer of varnish is required to increase the gloss and scratch resistance of the tinplate surface, at the same time increase a certain hardness, so that the printed surface coating film has a certain flexibility and corrosion resistance. The varnish should have the following functions:

Ⅰ. High hardness, strong adhesion, can withstand the processing deformation in the later process.

Ⅱ. Good color retention, the solvent in the varnish cannot bleed or fade the ink.

Ⅲ. Match with white paint or base oil, do not attack white paint or base oil.

FAQ:

Q: What is the MOQ for tinplate printing order?

A: Due to mass printing and production set up, minimum order quantity is roughly 2,000 ~3,000 pcs for each size.

Q: When can I get the price?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

Q: Do you make tools by yourselves?

A: Yes, we make all tools by ourselves. We have an in-house tooling department. So we can make custom molds at very low cost.

Q: Do you have any special varnishing effect in metal decoration?

A: In addition to traditional glossy and matted varnishes, we can offer crackle, wrinkle and pearl varnishes.

Q: What is your terms of delivery?

A: We accept EXW, FOB, CFR, CIF,etc. You can choose the one which is the most convenient or cost effective for you.

Q: What is your delivery time?

A: Usually within 15~20 days after getting deposit and confimed the sample.