07-14/2021

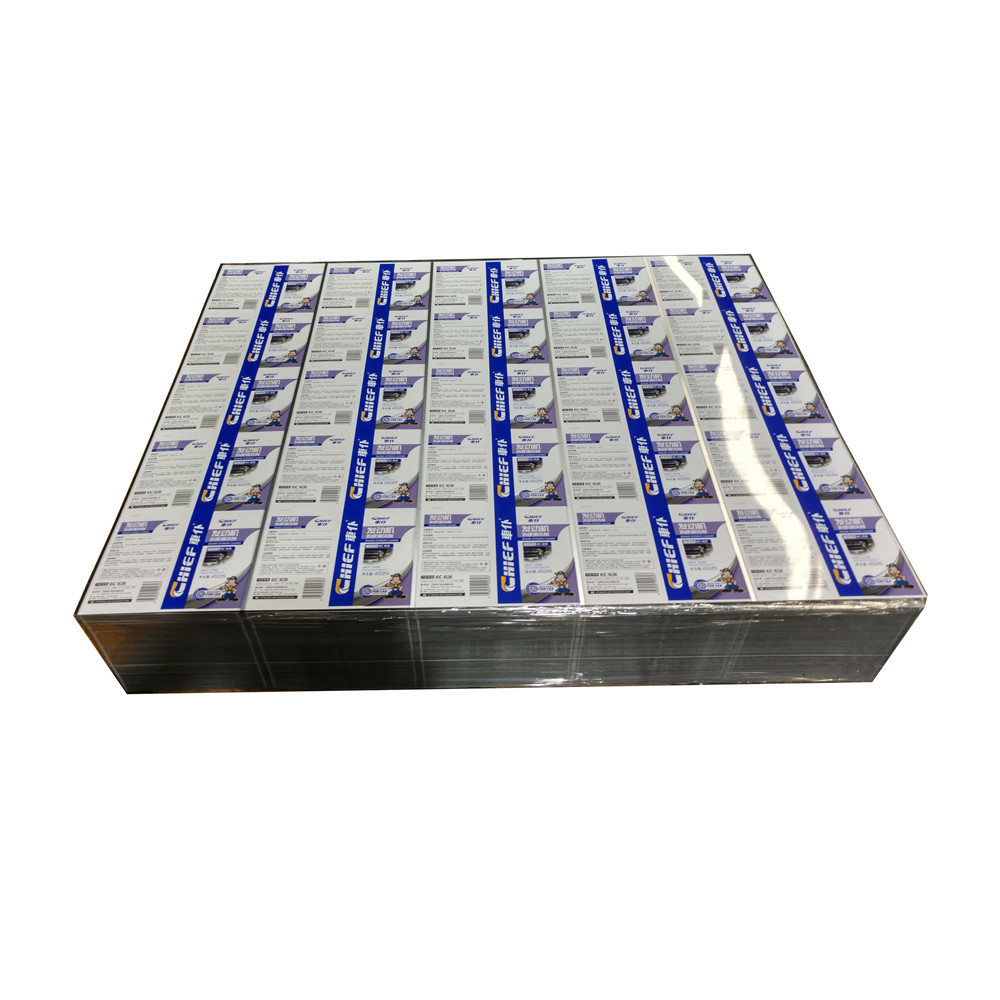

After the tinplate is subjected to the internal coating and external application process, the tin sheet printing can be operated on the machine.Since the tinplate surface is smooth, does not digest and absorb printing inks, and has the necessary strength and thickness, therefore, tin sheet printing is usually selected by offset printing. Basic principles: immiscibility of oil and water, dot conformation and fineness, purposeful absorption.