1. The tinplate of the the tin plate company is printed and the ink stays on the surface, and it must be dried and solidified by some form of heat energy;

2. The tin layer on the surface of the tin sheets is bright, and it is black according to the spectral characteristics. Therefore, a layer of white paint must be applied to the surface of the tin sheets before color printing. Of course, sometimes according to the special artistic effect of the product pattern, it can also be partially painted with white Paint or directly use the appearance of tin sheets itself;

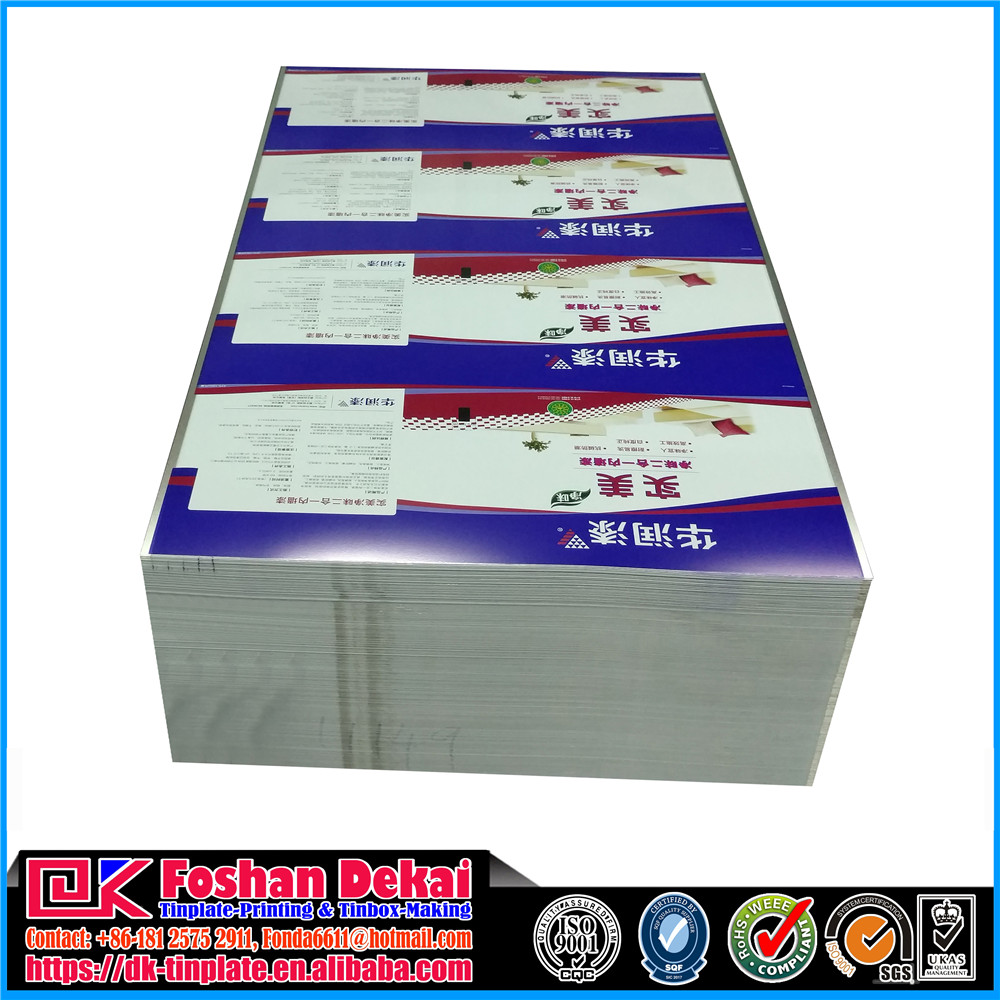

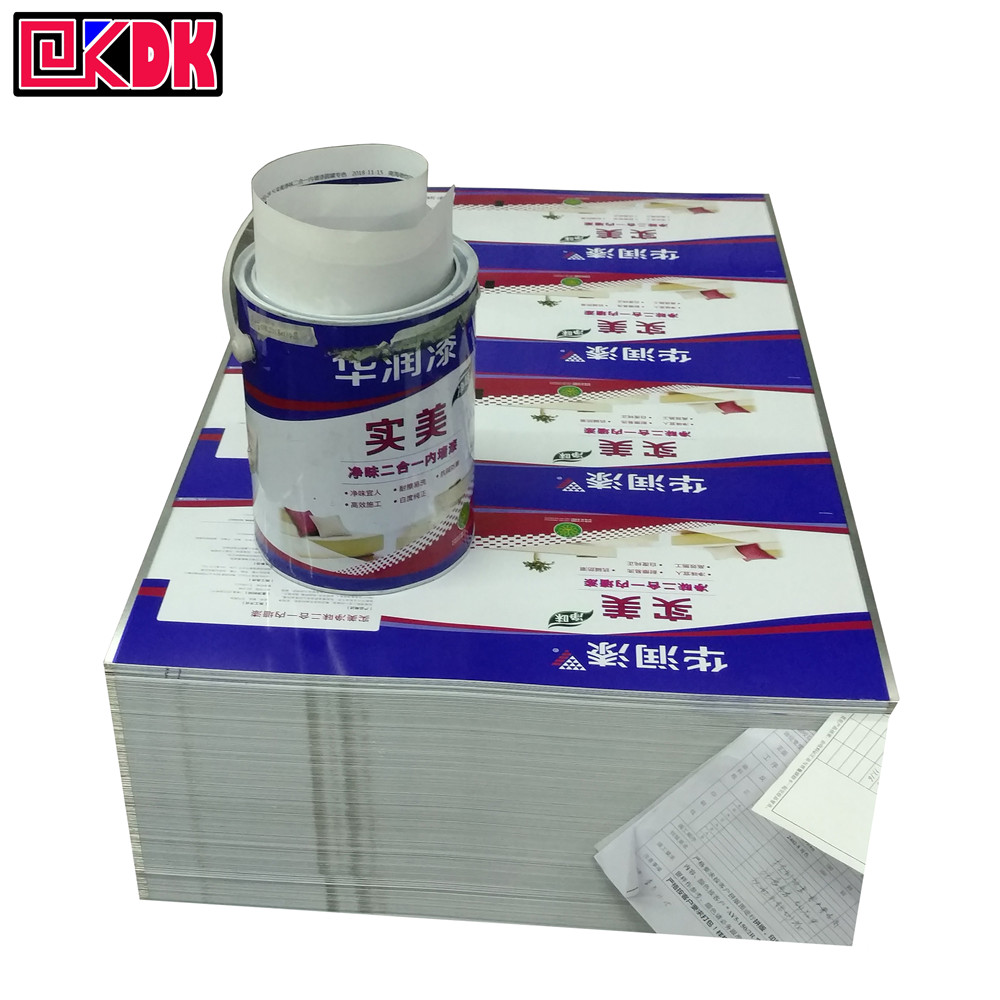

3. After the tinplate is printed on the finished product, tin plate sheet printing needs to be transferred to the next process for mechanical processing. The tin sheets box manufacturer makes various shapes of containers or other packaging. And in the process of mechanical processing, the ink coating on the surface of the tinplate must be resistant to mechanical shock , Anti-extension. Special products such as canned containers, etc., the ink coating must have the physical properties of resistance to high pressure cooking. This requires excellent adhesion between the ink coating and the surface of the tinplate.