09-24/2025

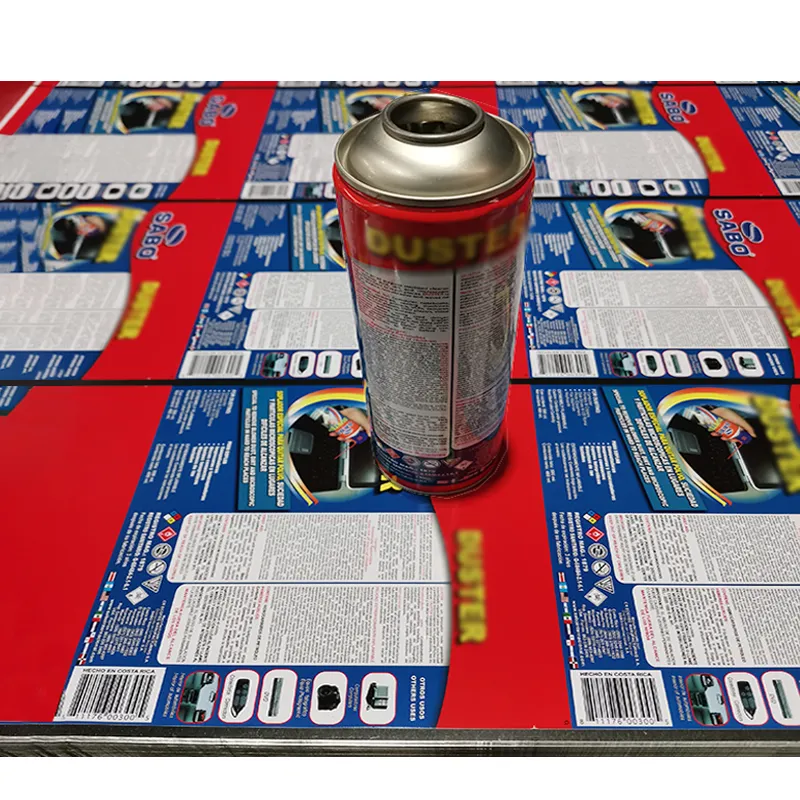

Carrying tinplate aerosol cans on board increases the pressure difference between the internal and external pressures, potentially causing them to expand or even explode. Even high-quality cans cannot fully protect against the risks posed by high-altitude, low-pressure environments.