In the packaging industry, aerosol cans are widely used for packaging various liquids and gases due to their high efficiency, convenience and reliability. However, for the packaging of acidic and alkaline liquids, especially aerosol cans used in industries such as food, cosmetics, and detergents, whether the contents can be safely stored is a crucial issue. Tinplate aerosol cans, as a common metal packaging container, are they suitable for storing acidic or alkaline liquids? When facing this problem, it involves not only the chemical stability of tinplate, but also the corrosion resistance, air tightness and safety of long-term storage of the material.

This article will explore this topic in depth from multiple angles, analyze whether tinplate aerosol cans are suitable for storing acidic and alkaline liquids, and answer related questions that consumers and manufacturers may encounter when using tinplate aerosol cans.

What are tinplate aerosol cans?

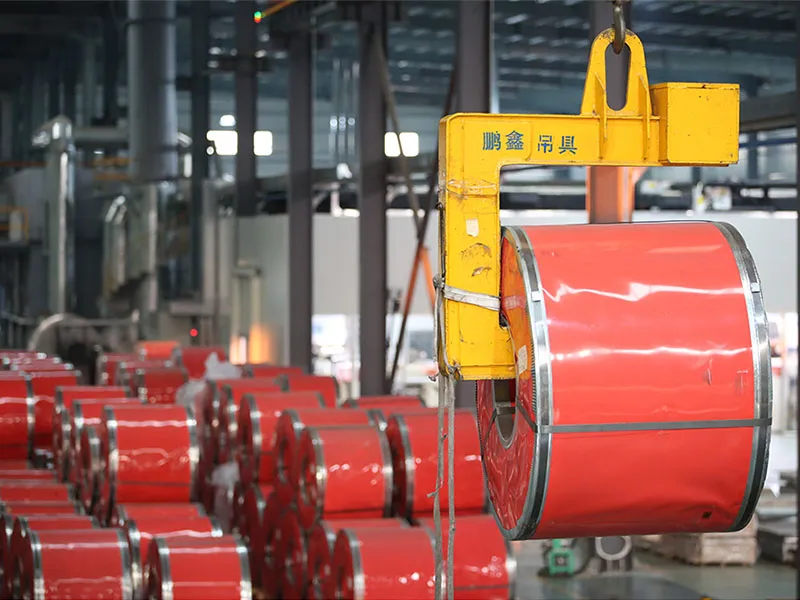

Before understanding whether tinplate aerosol cans are suitable for acidic and alkaline liquids, we first need to clarify what tinplate aerosol cans are. Tinplate, also known as tin-plated steel, is a steel plate coated with a layer of tin on the surface. This layer of tin can not only improve the corrosion resistance of the steel plate, but also enhance its surface finish and printability. Tinplate aerosol cans refer to aerosol cans made of tinplate, which are usually used to store spray products such as detergents, cosmetics, air fresheners, etc.

The advantages of tinplate aerosol cans include high strength, good corrosion resistance and suitability for large-scale production. However, whether this packaging material can withstand long-term storage of acid and alkaline liquids depends on its tin coating, sealing and the quality of the lining material.

What types of liquids are suitable for tinplate aerosol cans?

Tinplate aerosol cans are widely used in the packaging of a variety of products, especially in the fields of cosmetics, food and household cleaning products. Typical products packaged in tinplate aerosol cans include:

● Cosmetics: hair spray, perfume, facial spray, etc.

● Food: spray oil, spray cream, etc.

● Cleaning: detergent, deodorant, etc.

The common feature of these products is that they have high requirements for the sealing, corrosion resistance and ability of aerosol cans to effectively withstand internal air pressure. For these products, tinplate aerosol cans can usually meet their packaging needs and provide certain protective functions.

Characteristics and challenges of acid and alkali liquids

Acid and alkali liquids usually include strong acids, weak acids, strong bases and weak bases, etc., with different chemical activities. For example, common acidic liquids such as vinegar, lemon juice, and certain detergents, and alkaline liquids such as sodium hydroxide solution (caustic soda), certain detergents, etc. When they come into contact with metal materials, chemical reactions usually occur, causing corrosion or oxidation of the metal.

Acidic liquids have a low pH value and are easy to corrode the metal surface; while alkaline liquids cause corrosion by destroying the surface protective layer of the metal. Tinplate aerosol cans themselves are tin-plated. The tin layer as a protective coating can enhance its corrosion resistance to a certain extent, but this coating also has limitations. Not all acid and alkali liquids can be in contact with it for a long time without reacting.

Are tinplate aerosol cans suitable for acidic liquids?

1. Chemical reaction between acidic liquid and tinplate

Acidic liquids, especially strong acids such as sulfuric acid and hydrochloric acid, and some weak acids (such as citric acid, acetic acid, etc.) are prone to cause corrosion of metals when they come into contact with metals. Although the tin layer of tinplate aerosol cans can provide a certain degree of anti-corrosion protection, if the pH value of the acidic liquid is too low, the protective effect of the tin layer may be weakened, eventually leading to corrosion.

Specifically, acidic liquids can dissolve or erode the tin layer, exposing the metal itself to the liquid and increasing the risk of corrosion. This phenomenon is more likely to occur in aerosol cans that have been stored for too long or are not well sealed.

2. Why can some acidic liquids be stored in tinplate aerosol cans?

Although acidic liquids are highly corrosive, not all acidic liquids cannot be stored in tinplate aerosol cans. Weak acid liquids, such as some vinegars, lemon juice, etc., usually have less effect on tinplate because they have low acidity and the tin layer can effectively provide protection. In addition, some food-grade acidic liquid packaging often uses additional lining coatings to further enhance the tolerance of tinplate aerosol cans to acidic liquids.

3. How to prevent acidic liquids from corroding tinplate?

In order to prevent acidic liquids from corroding tinplate aerosol cans, manufacturers can take the following measures:

● Strengthen the tin layer: Increase the thickness of the tin layer to make it more resistant to corrosion by acidic liquids.

● Use lining coating: Apply an anti-corrosion coating to the inner wall of the aerosol can to increase the protection against acidic liquids.

● Improve sealing: Ensure the sealing of the aerosol can to prevent acidic liquids from being exposed to the air for a long time.

Are tinplate aerosol cans suitable for alkaline liquids?

1. Corrosion reaction between alkaline liquids and tinplate

Similar to acidic liquids, alkaline liquids also have a certain corrosive effect on metals, especially strong alkaline solutions, such as sodium hydroxide, which can destroy the surface protective layer of the metal and cause corrosion. For tinplate aerosol cans, the storage of strong alkaline liquids also poses potential risks, especially when no additional protective layer is added, and long-term contact may accelerate the dissolution or oxidation of the tin layer.

2. Why are some alkaline liquids suitable for storage in tinplate aerosol cans?

However, not all alkaline liquids will cause damage to tinplate. Mild alkaline liquids, especially low-concentration alkaline solutions, have less impact on tinplate aerosol cans. In this case, the tin layer can still effectively play a protective role and no significant corrosion will occur. In addition, some products such as household cleaners contain slightly alkaline ingredients, which usually do not cause damage to aerosol cans.

3. How to enhance the adaptability of tinplate to alkaline liquids?

Similarly, in order to increase the adaptability of tinplate aerosol cans to alkaline liquids, the following measures can be taken:

● Add lining coating: Use anti-alkali coating or plastic lining to prevent alkaline liquids from directly contacting the metal surface.

● Improve tinning process: Improve the quality of tinning process, increase the thickness of tin layer, and enhance alkali resistance.

Foshan Dekai Metal Packaging Co., Ltd., located in the industrial hub of Foshan, Guangdong, is a prominent manufacturer of metal packaging solutions. With advanced FUJI UV printing lines and automated production systems, our 50,000-square-meter factory is optimized for large-scale production of tinplate materials and aerosol cans. We pride ourselves on delivering customized packaging solutions tailored to meet the specific needs of wholesale buyers.