Tinplate aerosol cans have been widely used in industries, daily chemicals and food due to their strong corrosion resistance, strong structure and excellent sealing performance. However, although aerosol tin cans are widely used, the characteristics of their materials determine their scope of application, and they are not suitable for all substances.

This article will explain in detail the applicable and taboo contents of tinplate aerosol cans, and analyze what tinplate aerosol cans can and cannot be put in based on their performance characteristics.

What are tinplate aerosol cans?

1. Material characteristics of tinplate aerosol cans

Tinplate refers to a thin steel plate with a layer of tin on the surface. It is widely used in the packaging field because of its good corrosion resistance and high hardness. Aerosol tin cans are a sealed metal container, usually equipped with a valve that allows the liquid, gas and other substances inside to be sprayed out in a mist form.

The special feature of tinplate aerosol cans is that they have a tight structure, which can keep the contents from contacting the outside world during use, effectively extending the shelf life. In addition, the excellent corrosion resistance and sealing properties of tinplate also make aerosol tin cans have good pressure tolerance and can remain stable under high air pressure.

2. Production process of tinplate aerosol cans

The production of tinplate aerosol cans involves multiple processes, mainly including cutting, forming, welding and sealing. During the production process, the tinplate sheet needs to be surface treated to ensure that the aerosol tin cans have good sealing and corrosion resistance. The valves and nozzles of aerosol tin cans usually use high-precision technology to ensure that the contents can be accurately sprayed out under high-pressure environments. It is precisely because of these strict production processes that tinplate aerosol cans can contain and spray a variety of substances such as liquids, powders, and gases.

What products are suitable for tinplate aerosol cans?

Products suitable for tinplate aerosol cans:

1. Cleaning products

2. Cosmetics and personal care products

3. Industrial and home maintenance products

4. Pesticides and deodorants

1. Cleaning products

Tinplate aerosol cans are widely used to load various cleaning products, such as kitchen degreasers, bathroom cleaners, etc. These products are usually corrosive or volatile, but the tin layer of the tinplate can can provide sufficient protection so that the contents do not react adversely with the can. In addition, the spray design of aerosol tin cans makes the use of cleaning products more convenient. Users can spray directly to the area that needs to be cleaned to achieve better cleaning results.

2. Cosmetics and personal care products

Many cosmetics and personal care products are also packaged in tinplate aerosol cans, such as hair spray, shaving foam, dry cleaning spray, etc. These products are characterized by light texture and low demand, and the amount can be precisely controlled by spraying aerosol tin cans. The moisture resistance and sealing properties of tinplate ensure that these products will not deteriorate in the cans and are easy to carry. Aerosol tin cans can also effectively isolate the outside air, so that the contents can maintain stable active ingredients.

3. Industrial and household maintenance products

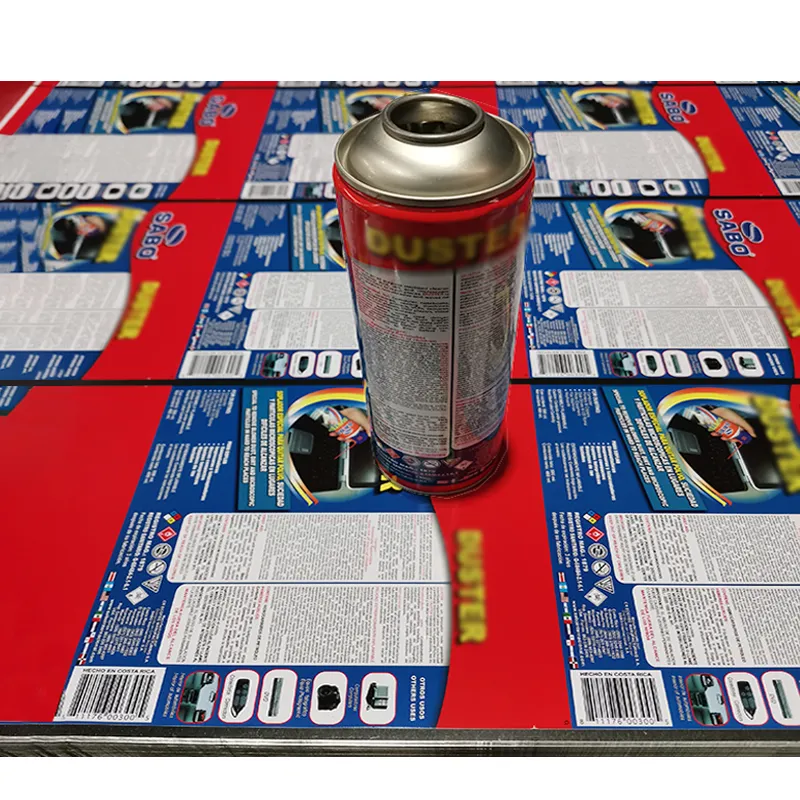

In the industrial field, tinplate aerosol cans are widely used to load chemical products such as spray paint, lubricants, and rust inhibitors. These products are often corrosive, but the protective properties and sealing properties of tinplate ensure that the cans will not be easily corroded. In addition, aerosol tin cans can provide a stable spray function, so that industrial chemicals can be evenly distributed to ensure the working effect.

4. Insecticides and deodorants

Tinplate aerosol cans are often used to pack household products such as insecticides, mosquito repellent sprays, and air fresheners. The spray effect of these products is crucial, and tinplate aerosol cans can provide a stable spray effect, so that the agent can be evenly distributed in the air to achieve good results. At the same time, the sealing of tinplate ensures that products such as insecticides will not leak or deteriorate during storage, improving the safety of use.

What substances cannot be contained in tinplate aerosol cans?

Substances that cannot be contained in tinplate aerosol cans:

1. Highly corrosive acidic and alkaline substances

2. Gases with particularly high pressures

3. Strong oxidants or highly volatile substances

1. Highly corrosive acidic and alkaline substances

Although the surface of tinplate is protected by a tin layer, the protective layer of tinplate aerosol cans cannot completely isolate the reaction of some highly corrosive acidic and alkaline substances. Strong acids such as concentrated sulfuric acid and concentrated hydrochloric acid will react chemically with the tin coating and even corrode the steel itself, causing the can to leak or even burst. In comparison, plastic or glass containers have better protection against strong acids and alkalis. Therefore, for safety reasons, highly corrosive acidic and alkaline substances are generally not suitable for tinplate aerosol cans.

2. Gases with particularly high pressures

Although tinplate aerosol cans can hold gases at a certain pressure, the pressure resistance of tinplate may be insufficient for some high-pressure gases, such as compressed hydrogen or compressed oxygen. High-pressure gases in aerosol tin cans will generate strong internal pressure on the can body, and exceeding the safe pressure value may cause the can body to deform or even explode. For safe use, high-pressure gases are usually packed in high-pressure cylinders or other professional containers rather than tinplate aerosol cans.

3. Strong oxidants or highly volatile substances

Strong oxidants such as hydrogen peroxide and some organic peroxides have extremely strong oxidizing properties and are prone to react with tinplate, causing corrosion of the can body and even danger. In addition, some highly volatile solvents, such as ether and acetone, have a high vaporization rate and may generate a large gas pressure in a sealed can body, causing the can body to deform or burst. Therefore, such highly volatile solvents are usually not packaged in tinplate aerosol cans.

How to use tinplate aerosol cans safely?

1. Avoid storage in high temperature environments

Tinplate aerosol cans have a certain amount of pressure inside. High temperatures can cause the contents to vaporize, which in turn increases the internal pressure and may even explode in extreme cases. Therefore, tinplate aerosol cans should be stored away from direct sunlight or near heat sources, especially in hot environments.

2. Avoid puncture or impact

Although the structure of tinplate aerosol cans is strong, when punctured or impacted by external forces under high pressure sealing, it may cause the can to rupture and cause the internal contents to spray out. Therefore, during use and storage, be careful and avoid direct contact between sharp objects and the can.

3. Avoid fire and electric sparks

Many substances in tinplate aerosol cans are flammable or explosive chemicals, such as spray paint, pesticides, etc. These products may cause combustion or explosion after encountering fire. Therefore, during use, stay away from fire sources such as open flames and electric sparks to prevent safety accidents.

What are the advantages and disadvantages of tinplate aerosol cans?

1. Advantages: Stable structure and strong sealing

The structure of tinplate aerosol cans is very stable and can withstand large external impacts. In addition, its good sealing ensures that the contents will not leak or deteriorate easily, making it an ideal packaging material for a variety of substances such as liquids, gases, and powders.

2. Disadvantages: Cannot load highly corrosive or high-pressure substances

Although tinplate aerosol cans perform well in most applications, the limitations of its material make it unsuitable for loading highly corrosive or high-pressure substances. In addition, due to the conductivity of tinplate, extra care is also required when storing flammable and explosive gases to avoid safety hazards.

3. Disadvantages: Relatively high cost

Compared with plastic materials, tinplate aerosol cans have a higher production cost and a complex production process, especially in some low-cost product packaging. However, its excellent sealing and protection properties make tinplate aerosol cans still competitive in high-demand application scenarios.

Who is Dekai and what do you supply?

Dekai is a leading metal packaging company based in Foshan, China. With over 50,000m² of factory space, we manufacture and supply a wide variety of metal packaging products including tinplate, aerosol cans, end-caps, and sheet-fed printed metal. Our factory offers one-stop procurement solutions: raw material sourcing, four-color and two-color UV tinplate printing lines, high-speed dome can production, plus lid, cutting coating, top and bottom production. Looking to buy affordable tinplate? Contact us please!