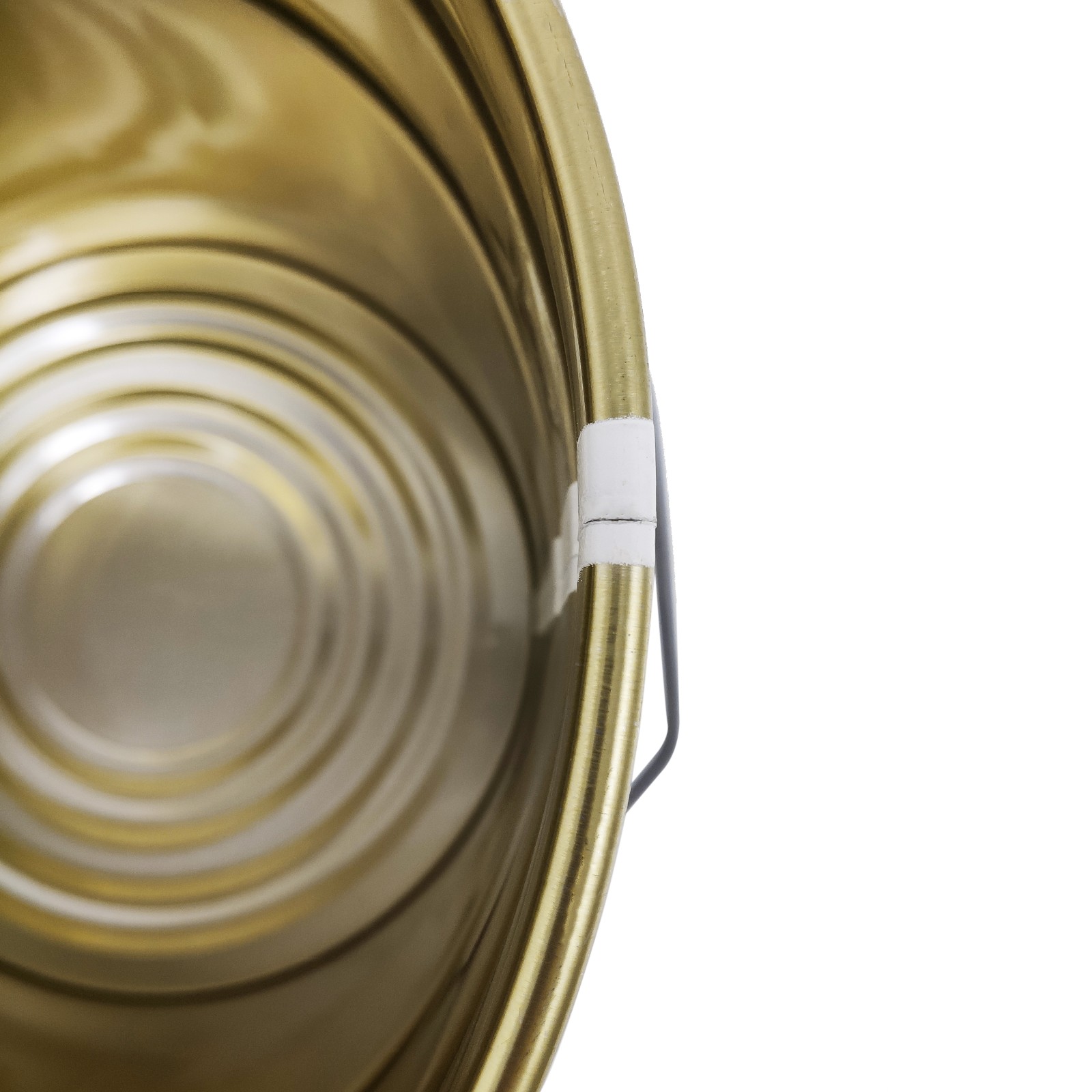

Specification of 20L White Chemical Tins Steel Drum With Handle:

Product name | 20L White Chemical Tins Steel Drum With Handle |

Size | large,mini,any size is accepted |

Material | Tinplate |

Tickness | 0.20-0.38mm |

Printing | Offset printing in CYMK / PMS as per your artwork. |

Design | AI,PDF,PSD format above 300dpi, or provide our die cut template to you |

Unit price | Depends on your final quantity |

Shipment terms | EXW,FOB,CIF |

Payment terms | T/T 30%deposit,70% balance should be paid before shipment |

Package | 1piece into poly bag; N/W less than 15kg/ctn |

Quality assurance:

1) The Right Material, First Time: Quality is the hallmark of our reputation.

2) Strict quality control,ensure any product satisfied with yours application .

3) Quality Control:

Material Inspection → Drawing and Samples` → Inspection →Correction of Machine and Equipment → Trial production → Finished Production Testing →The Third inspect department

Certificate: Approved by the ISO 9001

Our Services:

1) OEM logo/customized 3D design is welcome.

2) Good at embossed design, height of tins can be adjust.

3) Over 3000 existing mould for option.

4) Factory price & delivery on time.

5) 24h online service and quick response.

6) After sale for 3 month.

7) Quality control: 1 QC corresponds to 6 workers; inspection welcome.

8) Sample making time: 7-10 days after your confirm the spread graphic.

9) Mass production lead time: approx 25 days according to MOQ

10) Professional packaging, like shrink pack, clients can put products into market directly.

What is tin drum ?

Tin drums are commonly called tin cans, tin boxes, which are tins made of tinplate. Tinplate is made of tin on the surface. For protection. Generally speaking, in order to exquisite packaging, printing is used, commonly known as printed tin cans.

characteristics of chemical tin drum.

Chemical tin drums have the advantages over other packaging materials:

1. Good mechanical properties: Compared with other packaging containers, such as plastic, glass, and paper containers, tin drums have high strength, good rigidity, and are not easy to break. Not only for small sales packaging, but also the main container for large transport packaging.

2. Excellent barrier properties: Tin drums have better barrier properties than any other material, and have good gas barrier properties, moisture resistance, light-shielding properties, and fragrance retention properties. Coupled with reliable sealing, they can reliably protect the product.

3. Mature technology and high production efficiency: tin drums have a long history of production. The mature technology has a complete set of production equipment that is matched with it. The production efficiency is high and it can meet the packaging needs of various products.

4. Exquisite decoration: metal material has good printing performance; the pattern trademark is bright and beautiful, and the packaging container made is attractive and is an excellent sales package.

5. Various shapes: tin drums can be made into various shapes according to different needs, such as square cans, oval cans, round cans, horseshoe shapes, trapezoids, etc., which not only meets the packaging needs of different products, but also makes the packaging container more change and promote Up for sale.

6. Recyclable: meet international environmental protection requirements and meet future product trends.