Specification of Tinplate Tins Cover For Paint Cans:

Product Name | Tinplate Tins Cover For Paint Cans |

Material | tin/tinplate |

Usage | packaging for paint,coating,oil,thinner,hardener and other chemicals |

Shape | Round shape |

Dimension | 238*225*435mm |

Thickness | 0.32mm,0.35mm,0.38mm |

Capacity | 22 liters |

Printing | CMYK 4C printing,customized printing |

Certificates | ISO 9001,UN approved |

Packing | Stack one by one,outside plastic bag,then pallet packing |

Delivery time | Within 20~30 days |

Product Show

Tins Cover

Tins Cover

Corrosion resistance of tinplate cover for paint tins.

Corrosion resistance is the most important property of tin plate. The acid leaching time lag value, iron dissolution value, tin plating grain size, alloy-tin galvanic value, and tin layer thickness are collectively referred to as the five corrosion resistance indicators of the tinplate. The comprehensive evaluation of the five indicators should be used to comprehensively measure the plating Corrosion resistance of tin plate.

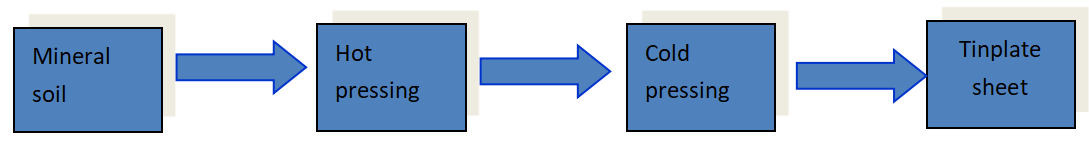

raw material of of tinplate cover for paint tins(metal paint can lids):

(1) Iron ore is produced in Australia and Brazil.

(2) Approximately 1 ton of tinpate sheet can be extracted from 1.8 ton of iron ore.

Application of tinplate cans cover(can ends):

The use of tinplate cans cover is very extensive. From packaging materials for food and beverages to grease cans, chemical cans and other miscellaneous cans, the strengths and characteristics of tinplate provide good physical and chemical maintenance of the contents.

1. Chemical containers

The tinplate raw material is solid, maintainable, non-deformable, shock-resistant, and fire-resistant. It is the best packaging material for chemicals.

2. Spray and other miscellaneous cans

Tinplate cans that can withstand high temperature and pressure, especially suitable for high-pressure filling spray cans.

Variable cans and delicately printed biscuit barrels, stationery boxes, and milk powder cans are all tinplate products.

manufacturing process of tinplate cover for paint tins:

Tinplate cutting → Basic tin cover stamping → primary side → injection → blistering → engraving line → riveting → forming process of storage can cover

Tinplate Tins Cover characteristics:

1. Thinning

2. Intensity

3. Corrosion resistance

4. Thermal conductivity

5. Conductivity

6. shielding

7. surface gloss, beautiful

8. Solderability