Design requirements of paint tins metal can lid:

1. Material thickness requirements. Different industries have different requirements. We need to optimize the design of paint tins metal can lid according to the material thickness requirements of the industry, so that the can lid produced can meet the basic packaging needs.

2. Tin plating. Because there are many different types of products, there are various requirements for the performance of tinplate lids, and their performance has a great relationship with the amount of tin plating. Therefore, we must pay attention to the requirements of applying tin plating, optimize the design of the head, especially optimize the selection of tinplate material.

3. Mechanical properties. Different packaging applications have different requirements on the mechanical properties of packaging materials, so when applying the performance of packaging materials, factors in the design of tinplate lids must also be considered.

In addition, we must also consider the size and specifications of the product to optimize the design and size of the can lid to ensure that the design of the paint tin can lid can provide reliable sealed packaging for the product.

The advantages of paint can tops:

1. Good mechanical properties: The can lid made of tinplate is stronger than other packaging materials, such as plastic, glass, paper, etc., and has good rigidity and is not easy to break. It can be made into the shape and style you want.

The metal can lid is mainly used to prevent deterioration, and it can be sterilized at high temperature without leakage. If a plastic cover is used, the high temperature will easily deform the cover and easily leak.

2. excellent barrier properties: tinplate lid has better barrier properties than any other material, gas barrier properties, moisture resistance, light-shielding properties, fragrance retention properties, plus reliable sealing, can reliably protect the product.

In addition, many tinplates are now easy to print, can be printed according to designs that cannot be used, and use food-grade inks to print safely.

3. mature technology and high production efficiency: tinplate cans have a long history of production, mature technology has a complete set of production equipment supporting it, high production efficiency, and can meet the packaging needs of various products.

Specification of Paint Tins Component Metal Can lid:

Volume | Can Part | Chuck | Couter | Inside coating | Outside coating |

Diameter | Diameter | ||||

10L | lid | 233mm | 8.5mm | gold/ | gold/ |

10L | Bottom | 222mm | 7.5mm | clear/ | clear/ |

18-20L | lid | 282mm | 7.6mm | plain | white/ |

18-20L | Bottom | 272mm | 8mm | printing | |

18-20L | Bottom | 273mm | 8mm | ||

18-20L | Bottom | 272mm | 9.5mm | ||

18-20L | lid | 283mm | 13.2mm |

Hardness of Paint Tins Component Metal Can lid:

Code | Chineses | Japaness | American | Europen | International |

GB/T2520-2000 | JIS G3303-2002 | ASTM | DIN EN | ISO | |

T-2 | TH52+SE | T-2 | T-2(T53) | T52 | TH52+SE |

T-2.5 | TH55+SE | T-2.5 | TH55+SE | ||

T-3 | TH57+SE | T-3 | T-3(T57) | T57 | TH57+SE |

T-3.5 | |||||

T-4 | TH61+SE | T-4 | T-4(T61) | T61 | TH61+SE |

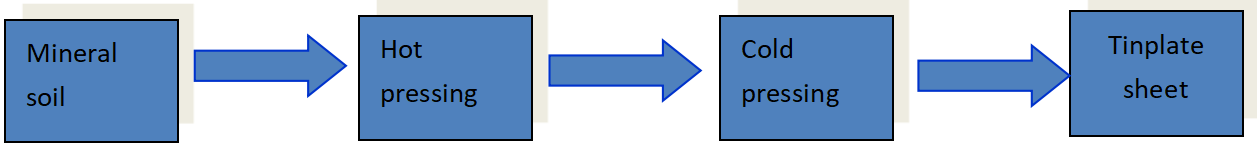

Tinplate raw material comes from:

(1) Iron ore is produced in Australia and Brazil.

(2) Approximately 1 ton of tinpate sheet can be extracted from 1.8 ton of iron ore.

Quality assurance of tin cans lids for paint tins:

1) The Right Material, First Time: Quality is the hallmark of our reputation.

2) Strict quality control,ensure any product satisfied with yours application .

3) Quality Control:

Material Inspection → Drawing and Samples` → Inspection →Correction of Machine and Equipment → Trial production → Finished Production Testing →The Third inspect department