Specification of Multicolor Printing Metal Tin For Chemical Can:

Product name | Multicolor Printing Metal Tin For Chemical Can |

Standard | AISI, ASTM, BS, DIN, GB, JIS (GB/T2520, JIS G3303, ASTM A623M, EN10202) |

Material | Tinplate sheet/Tinplate coil (MR SPCC) |

Steel type | MR grade for metal packaging |

Tin coating | 1.1~11.2g/m2 (1.1/1.1, 2.2/2.2, 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2) |

Temper Grade | T1~DR10 |

Annealing | BA,CA |

Passivation | 311GR |

Oiling | DOS |

Thickness | 0.23~0.38mm (Tolerance: +/-0.01mm) |

width | 508~960mm (Tolerance: 0~3mm) |

length | 712~1145mm |

Internal coating | Gold lacquer |

Outside printing | White coation+CMYK Printing+Varnish |

Application | For any matal packing Tin, Can, Bucket,Box, metal tin, chemical can etc(Food, oil, medicines, cosmetics, perfume,toys, chemicals, etc.) |

MOQ | 2 tons for each size |

Printing capacity | 4000 tons per Month |

Loading | Foshan/Guangzhou/Shenzhen |

Lead time | 15~25 days after receipt of 30% T/T deposit. |

Standard for Tinplate Temper:

Code | Chineses | Japaness | American | Europen | International |

GB/T2520-2000 | JIS G3303-2002 | ASTM | DIN EN | ISO | |

T-2 | TH52+SE | T-2 | T-2(T53) | T52 | TH52+SE |

T-2.5 | TH55+SE | T-2.5 | TH55+SE | ||

T-3 | TH57+SE | T-3 | T-3(T57) | T57 | TH57+SE |

T-3.5 | |||||

T-4 | TH61+SE | T-4 | T-4(T61) | T61 | TH61+SE |

Surface state of tinplate:

Type | Marks | Suface state | Characteristics |

Single Reduce | B | Bright Surface | Glazed surface obtained a thin layer of chromium and chromium oxide which deposits on the smooth. |

Double Reduce | R | Stone Surface | Glazed surface obtained a thin layer of chromium and chromium oxide deposit on smooth steel base featuring certain oriented stone figures. |

S | Silver Surface | Glazed surface obtained after melting treatment of electronicned raw material strip with rough matt surface. | |

M | Matte Surface | Matte Surface | |

R | Stone Surface | Glazed surface obtained a thin layer of chromium and chromium oxide deposit on smooth steel base featuring certain oriented stone figures. |

Metal tin raw material comes from:

(1) Iron ore is produced in Australia and Brazil

(2) Approximately 1 ton of steel can be extracted from 1.8 ton of iron ore

Quality assurance:

1) The Right Material, First Time: Quality is the hallmark of our reputation.

2) Strict quality control ,ensure any product satisfied with yours application .

3) Quality Control:

Material Inspection → Drawing and Samples` → Inspection →Correction of Machine and Equipment → Trial production → Finished Production Testing →The Third inspect department

What is Printing Metal Tin?

The printing metal tin process that uses hard materials such as metal tin plates and metal foils as substrates is called metal printing. Since the former metal printing substrates were mainly tinplate, it is also called tinplate printing. Although there are many types of substrates, Such as tinplate (tin-plated steel sheet), chemically-treated steel sheet (non-tinned steel sheet), chrome-plated steel sheet, zinc iron sheet, black steel sheet, aluminum plate, aluminum foil, aluminum stamping container, aluminum-tinplate composite material, etc., but tinplate is still used .The title of printing is also called iron sheet printing.

metal tin steel sheet (also called tin-plated sheet, tinplate) is a traditional can-making material, and it is the most widely used metal packaging plate. It is tin plated on both sides of a low carbon steel sheet.

1) Performance characteristics:

① It has a bright appearance, good corrosion resistance and can processing performance, easy to weld, suitable for coating and multicolor printing.

② Its drawing performance is not as good as aluminum plate. Most of them are made into three-piece can structures formed by welding and rolling, and can also be made into drawn pots.

2) Structure of metal tin sheet steel

The structure of metal tin sheet steel is composed of a steel substrate, a tin-iron alloy layer, a tin layer, an oxide film and an oil film.

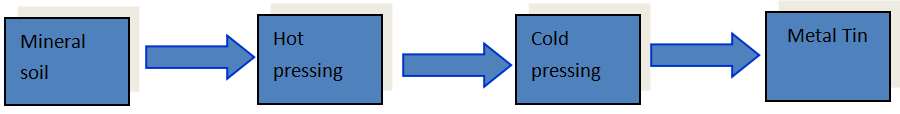

3) Production process of metal tin sheet steel

① Acid plating production process ② Hot dip tin plating process

4) Standard for metal tin sheet steel

① Standards and codes of common metal tin sheet steel

② Classification and representation of tin plate and steel strip Example of code mark:

Steel plate E2-T57-G-H-Q-I-0. The meaning is: equal thickness tin plating amount E2, hardness grade T57, surface condition G, passivation method H, oiling amount Q, surface quality I, size 0.

25 × 712 × 508-GB2520-88 The meaning is: The standard is GB2520-88.

5) The main technical indicators of metal tin sheet steel

①Type of steel substrate

②Specifications: thickness, width and length of the board

③Tin plating amount: Mass display of tin plating per unit area

④Tempering degree: indicates the comprehensive mechanical properties of tin plated steel sheet

6) metal tin sheet steel packaging unit

The internationally used metal tin sheet steel packaging unit is the "base box". A "base box" is an area unit. A base box contains 112 pieces of tin-plated thin steel plates with a size of 335.6mm × 508mm, with a total area of 20.23㎡.

7) Coatings

The role of coatings is to isolate the can wall from the contents, prevent corrosion and prevent the dissolution of heavy metals such as lead, iron, zinc, etc. to cause pollution to foods and other contents.

① Coating requirements in the can, The coatings in the can must meet the following requirements: The coating is an organic compound, and the main components are oil and resin.

② The coating layer isolates the article from the tinned layer and makes direct contact with the article. Must have the following characteristics:

Ⅰ. Non-toxic, odorless, odorless;

Ⅱ. The coating film is dense, basically free of pores, and has good corrosion resistance;

Ⅲ ,The coating film does not fall off when subjected to impact, folding, bending and other processing;

Ⅳ,Does not zoom during high-temperature welding Shedding without dissolution of harmful substances.