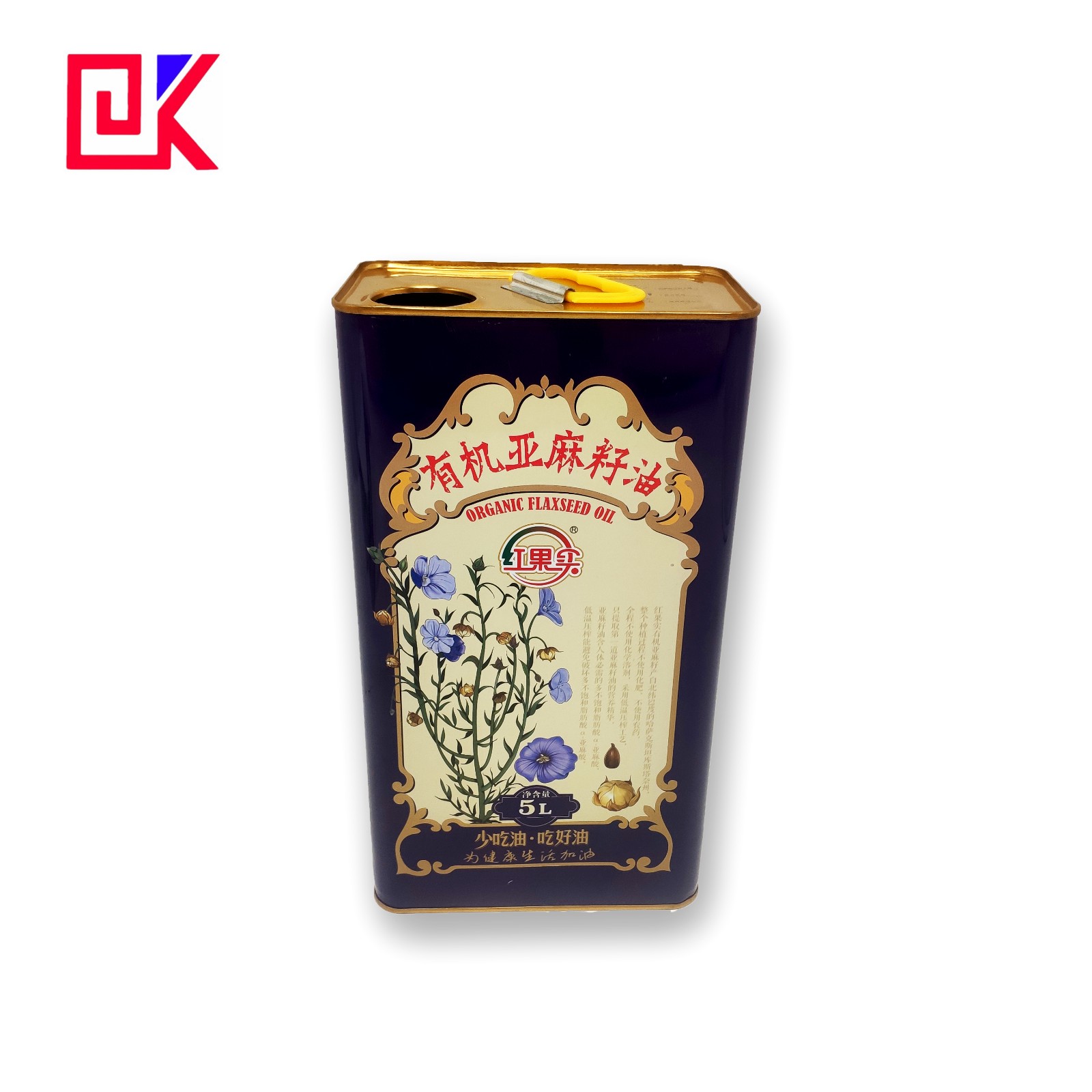

Specification of 5 L Organic Flaxseed Oil Tin Food Can:

Product name | 5 L Organic Flaxseed Oil Tin Food Can |

Description | A good packaging is the best and most cost-effective advertisement for your products such as candy, nut, cookie,chocolate and more. The metal container we produced is your best choice for its high quality and competitive price . |

Specifications | Product size: large,mini,any size is accepted Material: 0.21~0.28mm thickness tinplate for your choice design:Welcome your own design , we will protect your copyright if you have the legal copyright. Features : Recycle and durable ,eco-friendly, offset printing with good safety ink Three-piece structure ( lid, body and base) Hinged lid Vivid picture embossing on tin body Height is adjustable |

Printing | CMYK printing on outside of whole tin cans transparent varnish for inside tin it can be different according to your request |

Features | Recycle and durable eco-friendly offset printing with good safety ink |

Surface | Glossy/ matt, Embossing and debossing is acceptable |

Competitive price : | we are insist on competitive price for our customers to keep a long good relationships with each others |

Certificate | ISO 9001 |

Leadtime | 7-10 days for pre-production samples 25-30 days for mass production after sample approval |

Payment | 30% in advance,70% upon shipment |

Features of 5 L Organic Flaxseed Oil Tin Food Can:

Food grade material for food oil tin can internal coating and varnishing.

Multiple printing processes.

Shinny or gloss finish on surface.

Multiple structural processes.

Can be customized.

Quality assurance:

1) The Right Material, First Time: Quality is the hallmark of our reputation.

2) Strict quality control,ensure any product satisfied with yours application .

3) Quality Control:

Material Inspection → Drawing and Samples` → Inspection →Correction of Machine and Equipment → Trial production → Finished Production Testing →The Third inspect department

Tinplate food tin can printing has special requirements for inks:

(1) It has good adhesion and corresponding mechanical functions. Because tinplate food cans are printed at the end, they can be made into food cans, flaxseed oil tins,toys, metal photo frames, and barrels and cans of chemical products. Therefore, it is implored that printing inks have better adhesion and corresponding mechanical functions to tinplate food cans. In order to improve the ink adhesion, the tinplate food can is firstly primed before printing. White is the base color of all screens and has a very high brightness. Participate in other high-energy hue in the future, can improve the lightness of each hue to form a gradation.

(2) Requirements for white ink:

The appearance of tinplate food cans is snow-white (or yellow) and has a metallic luster. Before printing colorful graphics, the appearance needs to be painted white or printed white. Constrained by the ability of the ink masking, monochrome machines often need to be printed white twice. Whiteness can reach 75%. Whiteness is an important target for the quality of tinplate food can printing products. It is implored that the white ink has the outstanding binding force with the primer, and it does not turn yellow after being baked at high temperatures, and does not lose color under high temperature resistance. Priming tinplate food cans can add adhesion to tinplate food cans and has excellent binding power to white ink. The commonly used primer is epoxy amine based, with light color, no yellowing and aging after repeated baking, good flexibility and impact resistance.

(3) Requirements for color ink

The colorful inks printed on tinplate food cans, in addition to having a certain degree of water resistance, also need their special plea. Since the surface of tinplate food cans is not saturated with moisture and solvents, the baking needs are boring, so the ink should be heat-curable. Higher pigmentation power and durability are demanded. In addition to the basic functions of ordinary offset printing inks, iron printing inks should have heat resistance, strong ink film adhesion, impact resistance, good rigidity, cooking resistance and light resistance according to the characteristics of printing iron.

(4) Dry process of ink

In the production of tinplate food cans, the dullness of the ink is a messy physical and chemical reaction. To properly control the boring speed of the ink, to grasp the physical and chemical mechanism of the boring ink, to effectively carry out rapid printing operations and ensure product quality. If the ink is boring too quickly, it will reduce the normal transfer function of the ink, which will affect the normal production process. The formation of prints will be weak, the ink color will be faded, and the printing plate and the ink roller will show dry ink on the surface, which will hinder the transfer of ink. The layer expands outwards; the excessive amount of desiccant is added to form the adsorption of ink, and the blank part becomes dirty. And the ink is boring too slow and can cause overprinting difficulty, adhesion, adhesion, etc., and the sturdiness is reduced; it can simply form scratches in the conveying process. Therefore, the ink's boring speed should be suitable, too fast or too slow are obscure.

(5) Special layout of printing equipment

Due to the difference in the substrate, the auxiliary organization of the tinplate food can printing machine is also different from the printing paper offset printing machine. Tinplate food cans are insoluble in water and do not absorb solvents, so printing inks need to be baked at high temperature before the solvent evaporates and condenses. Therefore, drying equipment is usually required in printing process equipment. The entire automatic printing line for tinplate food cans is generally more than 50 meters in length, with fine and huge features. In addition, the tinplate food can printing machine is controlled by the use of magnet split and double sheet. The high hardness of the tinplate food can data also determines that the progressive continuous iron layout cannot be selected during the printing process. Layouts are different from offset presses for printing paper.

FAQ:

Q: Are you factory or trading company?

A: We are factory and professional for tin box for many years, welcome to visit our factory!

Q: What is tinplate? Are printed tins safe for food?

A: Tinplate is the steel electrolytically coated with a fine layer of tin for tin protective purposes. Tinplate is a high quality safe packaging material for food items. such as cookies candies, chocolate, etc. A food grade lacquer is coated on the inside of the tin to prevent corrosion and interaction of the tin with the food product and thus make it suitable for food storage.

Q: How do you print on the tins? Is it screened or offset printed?

A: Metal decoration is an offset printing process utilizing CMYK colors. Print is done on large metals first,then slitting into smaller piece for stamping and formation. Offset printing, Pantone Printing,White lacquer and White printing as per your requirements at different prices.

Q: How do I get a copy of you product catalogue or samples?

A: Our products and samples are free for you. Please note that it is our policy that the receiver pays for the service. If it is convenient for your company, please confirm this with us and give us your company name, detailed address, zip code, telephone number, courier service account number(Fedex,UPS,DHL,TNT, etc). We will do our best to help you.

Q: How should I design on a tin?

A: Before designing any graphics on a particular tin,we will furnish a dimension layout for positioning graphics. According to the tin construction,this positioning information is very important to ensure the proper placement of artworks onto each of the tin.