Tinplate sheet is a metal material widely used in food packaging. Due to its corrosion resistance, good processing performance and strong plasticity, it is widely used to make various packaging such as food cans, beverage cans, biscuit cans, etc. However, many people still have doubts about the anti-rust performance of tinplate sheet and its safety in food packaging.

This article will take "Will tinplate sheet rust? Can it be used to package food?" as the theme, and discuss in detail the material characteristics of tinplate sheet, whether it will rust, its role in food packaging and its safety.

What is tinplate sheet?

Tinplate sheet is a composite metal material composed of a low-carbon steel substrate and an outer tin-plated layer. Steel itself has the advantages of high strength and good plasticity, but it is easily oxidized by moisture or oxygen, causing rust. In order to avoid rust, people form a protective film by plating a layer of tin on the surface of the steel plate. As a metal with good stability, tin can prevent air, moisture and other corrosive substances from directly contacting steel, playing an anti-corrosion role. Therefore, tinplate sheet is actually the common name for "tin-plated thin steel sheet".

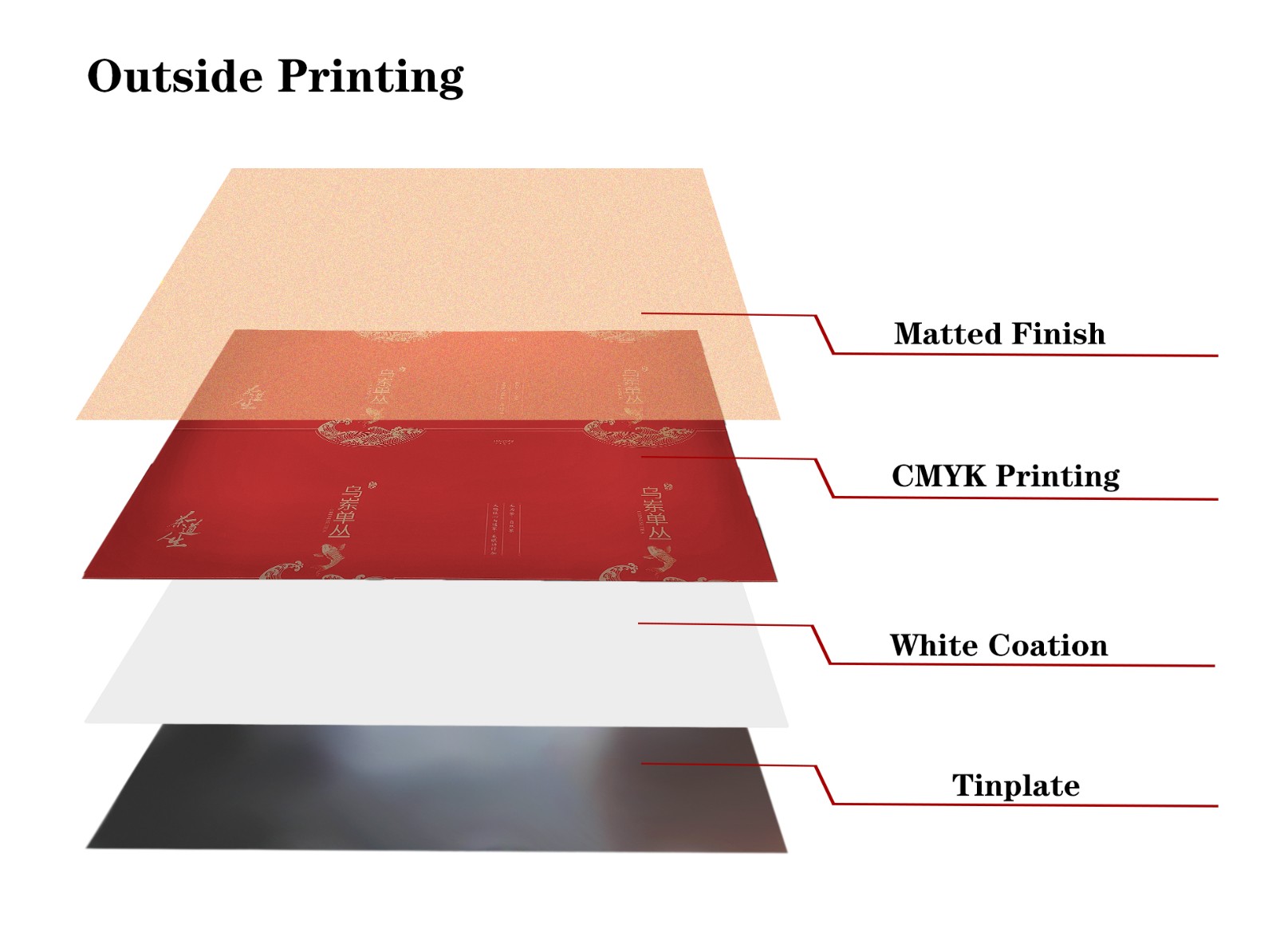

The surface of tinplate sheet is not only protected by a tin layer, but sometimes an organic coating such as polyester, epoxy resin and other materials is added according to the use requirements to further enhance its corrosion resistance and printing effect.

What are the applications of tinplate sheet?

The largest application area of tinplate sheet is food and beverage packaging. For example, common canned food, beverage cans, candy boxes, biscuit cans, etc. are all packaged in large quantities using tinplate sheet. In addition, tinplate sheet is also widely used in chemical packaging (such as paint cans, lubricating oil cans, etc.), daily necessities packaging, stationery, decoration and other fields.

The main reason why tinplate sheet is widely popular is its good corrosion resistance, strong plasticity, smooth surface suitable for printing, and environmental protection and recyclability.

Will tinplate sheet rust?

Although tinplate sheet is famous for its corrosion resistance, many people are still concerned about a question: Will tinplate sheet really not rust? What is its rust resistance? In order to answer this question, we need to understand in detail the rust prevention principle of tinplate sheet and its possible rusting under specific conditions.

1. The anti-rust principle of tinplate sheet

Tinplate sheet prevents rust by plating a layer of tin on the surface of the steel plate to form a physical barrier to prevent the steel from contacting with air and moisture. The thickness and uniformity of the tin layer play a vital role in the anti-rust performance of tinplate sheet. Generally, the thickness of the tin layer of tinplate sheet ranges from 1.5 to 11.2 microns, and the specific thickness is adjusted according to different uses.

Tin has good antioxidant properties and can effectively prevent the oxidation reaction of steel in most environments. At the same time, the tin layer also has a certain self-repairing ability. Even when the plating layer is slightly scratched or worn, a protective film can be formed around the tin layer to prevent further corrosion. Therefore, under normal circumstances, tinplate sheet is not easy to rust.

2. Will tinplate sheet rust under extreme conditions?

Although tinplate sheet has good anti-corrosion properties, tinplate sheet may still rust under certain extreme conditions. The following situations may cause the tinplate sheet's tin coating to fail or break, which in turn may cause the steel to be partially exposed to air or moisture, causing rust:

● Mechanical damage: During transportation or use, the surface of the tinplate sheet may be hit, scratched, or bent. These mechanical damages may damage the tin layer, exposing the steel substrate inside. If the steel is directly exposed to air or moisture, the risk of rust will be greatly increased.

● Strong acid and strong alkali environment: Although the tin layer has good antioxidant ability, in a strong acid or alkali environment, the tin layer may react chemically, causing the tin coating to be corroded and the protective effect to fail. Especially in food packaging, if the can contains acidic or alkaline foods (such as ketchup, lemon juice, etc.), if the can is not properly coated and protected, it may cause the can to corrode.

● Long-term exposure to humid environment: In a highly humid or long-term immersion environment, the tin layer may not be able to completely isolate water vapor, causing the tin coating to be corroded, and then the steel to rust.

In summary, although tinplate sheet has excellent rust resistance, it may still rust under extreme conditions. Therefore, when using tinplate sheet to make packaging, further coating treatment is usually carried out inside and outside the can to enhance its corrosion resistance.

Can tinplate sheet be used to package food?

Tinplate sheet is widely used in the field of food packaging, especially in canned food, where it almost dominates. However, many people have some doubts about whether tinplate sheet is suitable for food packaging, especially the impact of metal on food safety. Next, we will analyze the advantages of tinplate sheet in food packaging and its guarantee of food safety from multiple aspects.

Guarantee of food safety

The reason why tinplate sheet can be widely used in food packaging is first of all due to its excellent safety. In the production of tinplate sheet food packaging, in order to ensure that there will be no adverse reactions when food comes into direct contact with metal, tinplate sheet cans are usually coated on the inner wall. Commonly used coating materials include epoxy resin, polyester, etc. These coatings can not only isolate direct contact between food and metal, but also effectively prevent metal corrosion and ensure long-term preservation of food.

These inner wall coatings have undergone strict food safety testing and meet the food safety standards of various countries, which can effectively prevent heavy metal migration and corrosion products from entering food. In addition, these coatings are also highly chemically inert and will not react with acidic or alkaline foods, ensuring that the taste and quality of the food are not affected.

The combination of tinplate sheet's antiseptic properties and food packaging

Food packaging not only needs to consider the safety of the materials, but also ensure that the packaging can effectively extend the shelf life of the food. Tinplate sheet has become an ideal choice in the field of food packaging due to its excellent antiseptic properties. Whether it is canned vegetables, fruits, meat, or beverages and snacks, tinplate sheet packaging can provide good sealing and protection for food, preventing food from being damaged by air, moisture and microorganisms.

Tinplate sheet packaging can not only prevent food from oxidation and deterioration, but also effectively resist light exposure, preventing some foods from deteriorating due to light exposure. For example, canned foods usually need to be sterilized at high temperature, and tinplate sheet can withstand this high temperature and high pressure environment, ensuring that the packaging will not be deformed, damaged, and other problems, further extending the shelf life of the food.

Plasticity and aesthetics

In addition to functionality, another important advantage of tinplate sheet in food packaging is its good plasticity and aesthetics. Tinplate sheet can be easily made into packaging containers of various shapes through stamping, bending and other processes to meet the needs of different food packaging. At the same time, the surface of tinplate sheet is smooth and suitable for printing and spraying, which can achieve high-quality pattern and text printing, making the packaging appearance more exquisite.

For the food industry, packaging is not only a container to protect food, but also carries the display and marketing functions of the brand. Tinplate sheet packaging can effectively enhance the appearance value of the product and attract consumers' attention due to its excellent printing performance and diverse design options.

Environmental protection and recyclability

As a metal material, tinplate sheet has extremely high recyclability. Compared with other packaging materials (such as plastics and paper), the recycling rate of tinplate sheet is very high. Tinplate sheet can be 100% recycled, smelted and remade into new steel, and applied to new production processes. This not only reduces environmental pollution, but also saves resources. It is a very environmentally friendly packaging choice.

For the food industry, choosing tinplate sheet as a packaging material can not only improve the functionality and aesthetics of the product, but also conform to the environmental protection trend and meet consumers' demand for green packaging.

As a trusted manufacturer and supplier in China, DKtinplate specializes in metal packaging products such as tinplate printing, aerosol cans, and custom tops and bottoms. Our facility in Foshan spans 50,000 square meters and features advanced production equipment like FUJI UV printing lines and high-speed production lines. We offer bulk purchasing, wholesale discounts, and tailored solutions to meet your specific requirements. With ISO9001 certification and a dedication to quality, DKtinplate delivers superior products at competitive prices. Contact us now for quotes and promotions on premium metal packaging solutions.