Food packaging is a vital aspect of our daily lives. The choice of packaging material not only affects food quality and safety, but also directly impacts its storage life, transportation conditions, and consumer health.

Therefore, the choice of packaging material is particularly crucial. Among the many food packaging materials, tinplate is the most widely used, especially for canned foods.

This article will delve into tinplate sheet and attempt to answer the question, "Why is tinplate used in food packaging cans?"

What is tinplate sheet?

Tinplate sheet is a thin, tin-coated steel sheet coated with a very thin layer of tin. This tin layer prevents oxidation and corrosion of the steel itself and protects the food inside from environmental influences. Tinplate sheet is primarily composed of steel, and the outer tin layer effectively protects food from air, moisture, light, and other harmful factors that can damage the food.

Because tinplate sheet combines the strength and durability of steel with the chemical stability of tin, it is an ideal material for many food packaging applications, especially canned goods.

What are the advantages of tinplate as a food packaging material?

The widespread use of tinplate sheet in food packaging is no accident. Its popularity as the material of choice for food cans is inseparable from its many excellent properties. The following aspects highlight tinplate's core advantages in food packaging.

1. Excellent physical properties, ensuring packaging strength

The widespread use of tinplate sheet in food packaging stems primarily from its excellent physical strength. As a steel-based material, tinplate sheet possesses the inherent strength and durability of steel. Compared to other packaging materials such as plastic and paper, tinplate sheet effectively protects canned foods from external physical impact or compression. During transportation, storage, and shelf display, tinplate sheet packaging provides strong resistance to pressure, preventing food from spoiling due to external damage.

The strength of tinplate sheet is particularly well-suited for canned foods, which often undergo high-temperature heating and sealing processes, requiring the packaging material to withstand considerable pressure and temperature fluctuations. Tinplate's high pressure and heat resistance give it a clear advantage in canned food packaging.

2. Strong corrosion resistance prevents food spoilage

A key function of food packaging materials is to protect food from the outside world during storage and transportation, thereby preventing spoilage and contamination. Tinplate sheet offers excellent corrosion resistance, providing excellent protection for the food inside. Although tinplate sheet is based on steel, it is coated with a dense layer of metallic tin. This layer effectively protects the steel from atmospheric oxygen, moisture, and other corrosive substances, thereby preventing rust from forming on the packaging material and causing food quality problems.

Furthermore, the tin coating on tinplate sheet effectively isolates the acidic substances in canned food from contact with the steel, preventing the food's flavor and texture from being affected. For example, certain canned fruits, acidic beverages, or sauces contain high levels of acid. Ordinary metal materials may react with these acids, affecting the flavor and safety of the food. Tinplate sheet effectively resists this corrosion, preserving the food's original flavor.

3. Strong barrier properties, extending food shelf life

Tinplate sheet also offers excellent barrier properties, effectively preventing the effects of external factors such as oxygen, moisture, and light on food. This is particularly important for foods with demanding storage environments. Many foods oxidize upon contact with oxygen in the air, causing spoilage, decay, and loss of flavor. As a high-barrier material, tinplate sheet provides a near-complete barrier, preserving food freshness for extended periods.

Compared to materials like plastic, tinplate offers superior barrier properties, particularly against moisture and oxygen permeation. The tin coating on the surface of tinplate sheet effectively blocks the ingress of moisture and oxygen, preventing food from spoiling due to moisture or oxidation. This is one of the key reasons why canned foods can achieve a shelf life of several years.

4. Chemical stability ensures food safety

As a food packaging material, tinplate sheet also needs to meet the critical requirement of chemical stability. For packaging materials that come into direct contact with food, their chemical properties must be stable and not react with the food or release harmful substances. Tinplate sheet is coated with a layer of metallic tin, which is highly chemically stable and resists chemical reactions in acidic, alkaline, and salty environments. Therefore, even if the canned food contains acidic or alkaline substances, tinplate ensures the food's taste and safety are not affected.

In addition, the tin coating on tinplate sheet not only prevents direct contact between the food inside and the steel substrate but also has a certain antimicrobial effect. Tin's natural antimicrobial properties inhibit microbial growth to a certain extent, which is important for the long-term storage and safety of canned foods.

5. Highly recyclable and environmentally friendly

With increasing global awareness of environmental protection, the environmental friendliness of packaging materials has become a key consideration for food companies when choosing packaging. As a metal material, tinplate sheet has extremely high recyclability and reuse value. Discarded tinplate sheet packaging can be recycled and reused in the production of new metal products, reducing the consumption of natural resources.

Recycling tinplate sheet not only saves energy and reduces production costs, but also reduces environmental pollution caused by waste. Compared to non-biodegradable plastic packaging, tinplate sheet is a more sustainable packaging option. This is a key reason why many food companies choose tinplate as their preferred packaging material.

What are the specific applications of tinplate in food packaging?

Tinplate sheet is widely used in various types of food packaging, and its advantages are particularly evident in the following typical scenarios:

1. Canned Food Packaging

Canned food is one of the most common applications for tinplate sheet. Whether it's canned fruit, canned vegetables, canned fish or other processed foods, tinplate sheet provides an excellent packaging solution. Canned foods require high-temperature sterilization and sealing, and tinplate sheet can withstand the high temperatures and pressures of this process, ensuring food safety and quality.

2. Beverage Can Packaging

In addition to canned food, tinplate is also widely used in beverage packaging. This is particularly true for carbonated beverages, juice drinks, and beer. These beverages require excellent airtightness to prevent carbon dioxide from escaping and oxidation and deterioration. Tinplate sheet's high barrier properties and corrosion resistance effectively meet these requirements.

3. Candy and Biscuit Can Packaging

Tinplate is also widely used for packaging dry goods such as candy, chocolate, and biscuits. While these foods don't require the airtightness of canned goods and beverages, they still need to be moisture-proof and aesthetically pleasing. Tinplate sheet not only protects these foods from moisture but also enhances their appeal through attractive exterior printing.

Tinplate's Ease of Processing in Food Packaging

Tinplate sheet's widespread use in food packaging stems from its ease of processing. Tinplate combines the high strength of steel with its thinness and excellent plasticity, allowing it to be formed into a variety of shapes and sizes. Whether it's round cans, square cans, or other custom-shaped packaging, tinplate sheet can meet the design needs of food companies.

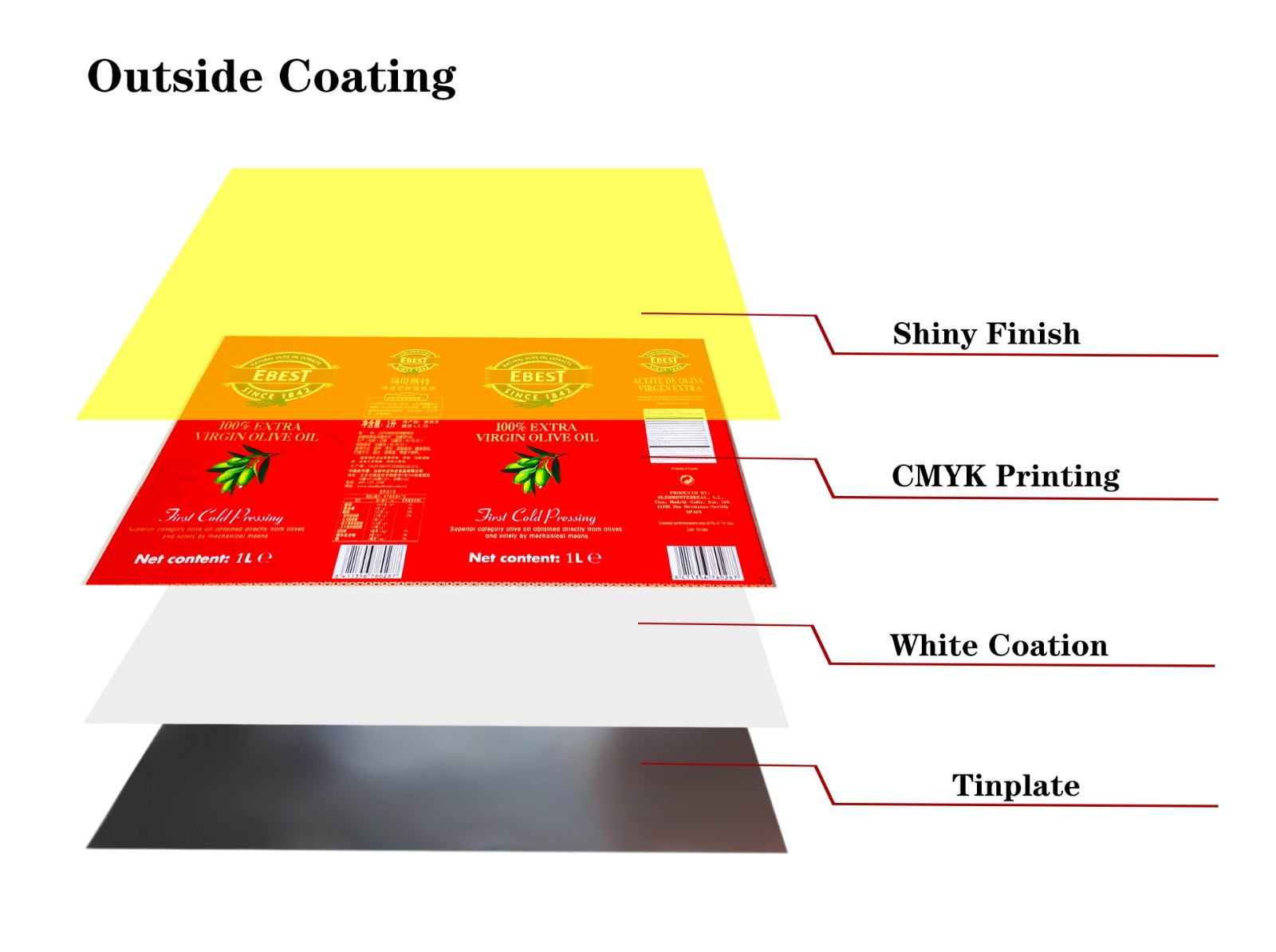

Furthermore, tinplate's smooth surface makes it suitable for printing and coating. Using offset printing or silk-screen printing, exquisite designs and brand logos can be printed on tinplate sheet, enhancing the visual appeal of food packaging. This is one of the reasons why many high-end food brands choose tinplate sheet as their packaging material.

What kind of equipment does Dekai use for production?

Dekai operates some of the most advanced automated production lines in the metal packaging industry. Our facility includes FUJI 4-color and 2-color tinplate printing lines, high-speed aerosol can production systems, and automated end and bottom cover machines. These technologies allow us to supply high volumes, superior quality, and low production costs to support your business with competitive pricing.