Tinplate sheet is a common packaging material widely used in industries such as food, beverages, and chemicals. Many people may have heard of tinplate sheet and even come into contact with it in their daily lives, but they may not be aware of its core composition and properties. Why is the steel sheet in tinplate sheet coated with a thin layer of tin? What is the practical significance of this process design?

This article will delve into this question, explaining in detail the reasons for tin plating on the surface of tinplate sheet and how it improves its material properties.

What are the components of tinplate sheet?

Tinplate sheet, also known as tinplate, is a composite material composed of steel and tin. Its core material is low-carbon steel sheet, coated with a thin layer of tin.

Low-carbon steel, a metal primarily composed of iron, possesses excellent mechanical properties such as high strength, good plasticity, and high toughness. However, a significant drawback of steel is its susceptibility to oxidation, especially in humid environments, where it reacts with moisture and oxygen in the air to form rust. Therefore, steel requires special treatment to prevent corrosion.

Precisely to address steel's susceptibility to corrosion, manufacturers apply a thin layer of tin to its surface. This layer, typically between 0.4 and 1.5 microns thick, is thin but highly functional, and is one of the core properties of tinplate sheet.

What are the unique properties of tin?

To understand why tin is chosen as a coating material, we need to first understand the unique properties of this metal. Tin is a chemical element with the symbol Sn and atomic number 50, and is classified as a metal in the periodic table. Its unique physical and chemical properties make it an ideal coating material for tinplate sheet.

1. Strong Corrosion Resistance

Tin's corrosion resistance is one of its most prominent characteristics. In air, water, and various acidic and alkaline environments, tin forms a dense oxide film that prevents corrosive media such as oxygen and moisture from coming into contact with the base metal. Therefore, tin-coated steel sheets effectively prevent rust even in humid environments, a key advantage of tinplate sheet in applications such as food packaging.

2. Non-toxic and safe

Tin is a non-toxic and harmless metal widely used in food and beverage packaging. Unlike other metals such as lead and chromium, tin does not contaminate food or beverages. Therefore, a tin coating provides additional safety when in contact with food, preventing direct contact with rust-prone steel and improving food hygiene standards.

3. Soft and ductile

One of the physical properties of tin is its relative softness and ductility. During the tinplate sheet manufacturing process, the tin layer adheres well to the steel surface, resisting cracking or flaking due to deformation. This property ensures that the tin layer remains intact during subsequent processing, such as bending, stamping, and cutting, maintaining its corrosion protection.

Why is tinplate sheet coated with tin?

Now that we understand the basic properties of tin, we can further explore why a tin coating is chosen for steel sheets during their manufacturing process.

Specifically, the tin plating process design has the following four functions:

1. Preventing oxidation and corrosion

2. Enhancing product safety

3. Maintaining product appearance and quality

4. Improving material processing performance

1. Preventing oxidation and corrosion

One of the most important applications of tinplate sheet is corrosion prevention. Although steel possesses high strength, it is highly susceptible to oxidation when in contact with air or water, forming rust. This rust not only weakens the steel's mechanical properties but also contaminates the materials within. Especially in food packaging, the presence of rust can significantly reduce product safety.

After applying a layer of tin, as an inert metal, tin is not easily chemically reacted with environmental factors such as oxygen and water. Therefore, the tin layer effectively protects the steel from corrosion, extending the lifespan of tinplate sheet. This anti-corrosion property makes tinplate sheet an ideal material for food and beverage packaging, such as cans and bottle caps.

2. Enhancing product safety

In the food and beverage packaging industry, product safety is paramount. Traditional iron or steel cans, due to the oxidizing properties of iron or steel, can easily react with the food or beverage inside, causing product deterioration or contamination. Tin, a non-toxic metal, effectively prevents direct contact between the steel and the contents, ensuring the food's taste remains intact and preventing the release of harmful substances into the food.

Thus, tin-coated tinplate sheet is a crucial material for food canning, ensuring that food remains safe and edible even during long-term storage.

3. Maintaining Product Appearance and Quality

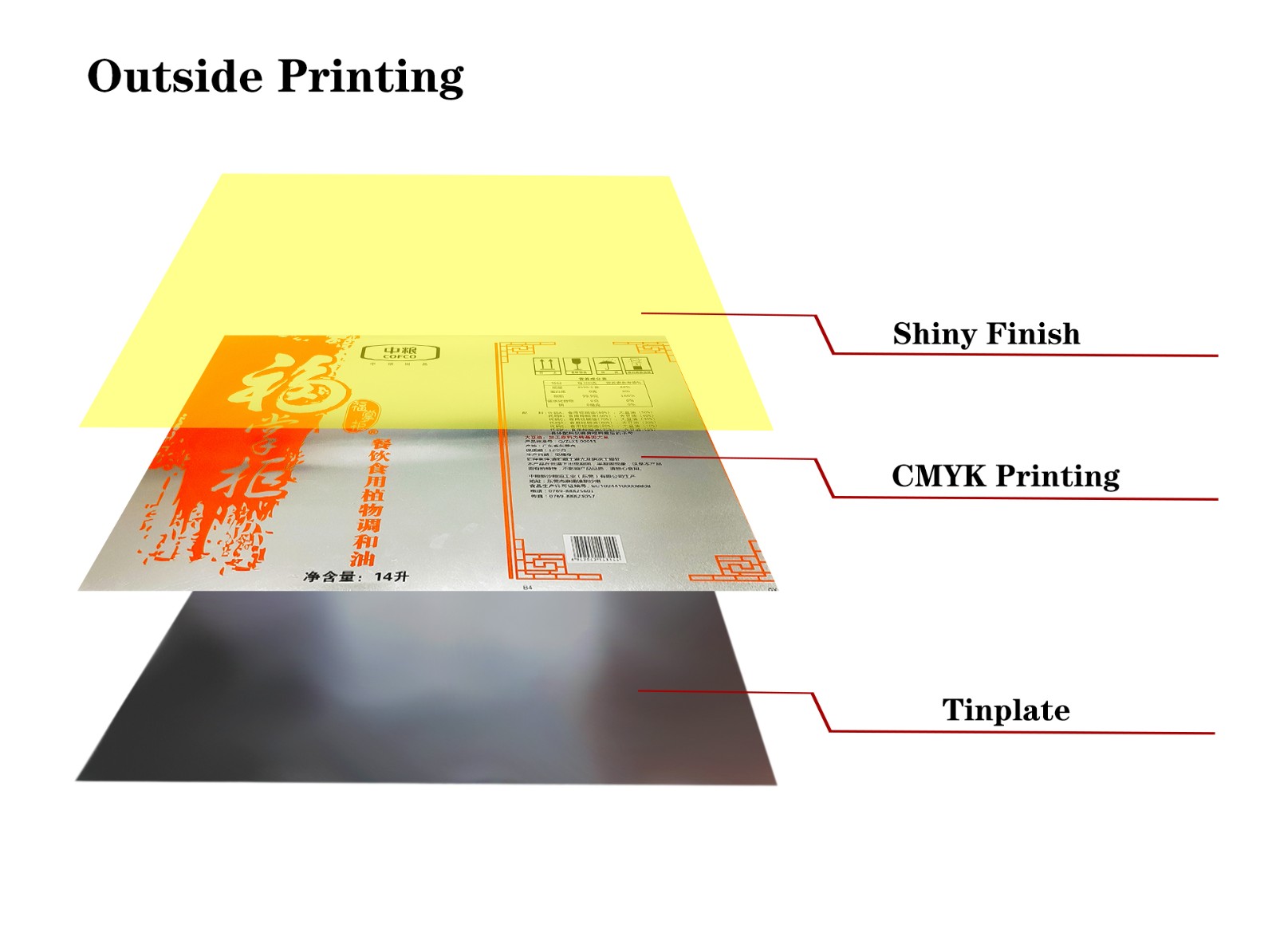

In addition to its corrosion-resistant properties, the tin coating also maintains the appearance and quality of tinplate sheet products. Steel surfaces are inherently rough and prone to oxidation over time. Tin coating creates a smooth, bright surface that offers a pleasant visual and tactile experience. This not only enhances the product's aesthetics but also provides an excellent base for subsequent printing and decoration processes.

For packaging products requiring high aesthetic quality, such as beverage cans and cosmetic containers, the glossy surface of tinplate sheet can enhance the product's appeal and increase consumer interest.

4. Improved Material Processing Performance

Tinplate sheet is not only used for packaging but also often undergoes folding, bending, and stamping during processing. Pure steel is prone to cracking or deformation during these processes. The protection of the tin layer maintains the integrity of the tinplate sheet's surface, reducing damage during processing, thereby improving the product's formability and yield rate.

The tin layer also reduces friction, preventing surface scratches during processing and ensuring the product's appearance quality. Therefore, tin plating not only provides corrosion protection but also enhances the performance of the tinplate sheet during subsequent processing and production.

What are the different tinning processes?

The tinning process for tinplate sheet can be categorized as hot-dip tinning and electroplating. Different tinning processes have varying effects on the performance of the final product.

1. Hot-dip tinning

Hot-dip tinning is a traditional tinning process in which steel sheets are immersed in molten tin to deposit a uniform layer of tin on the surface. The hot-dip tinning process is simple, resulting in a thicker tin layer and excellent corrosion protection. The disadvantage of this method is that the thickness of the tin layer is difficult to control, which may affect the smoothness and aesthetics of the material.

2. Electroplating

Electroplating is currently the most widely used tin plating process. It uses an electrochemical method to deposit tin ions into a thin coating on the surface of steel sheets. The advantage of electroplating is that the thickness of the tin layer is uniform and controllable, ensuring that the tin layer on each tinplate sheet meets the standard. The tinplate sheet produced by this method has a smooth and flat surface, making it ideal for applications such as food packaging and printed decoration that require high aesthetic standards.

The electroplating process also reduces tin usage and production costs while maintaining corrosion resistance. Therefore, electroplating has become a dominant method in modern tinplate sheet production.

What are the uses of tin-coated tinplate sheet?

Applications of tin-coated tinplate sheet:

1. Food and beverage packaging

2. Cosmetic packaging

Due to its superior properties after tin plating, tinplate sheet has become the material of choice in many industries.

1. Food and Beverage Packaging

As mentioned above, tinplate sheet's corrosion-resistant properties make it a valuable component of food and beverage packaging. Typical applications include canned foods, beverage cans, and milk powder cans. Tin-coated tinplate sheet ensures that food remains fresh and safe during extended storage, protected from environmental influences.

2. Cosmetic Packaging

High-end cosmetic packaging often requires excellent corrosion resistance and aesthetics. Tinplate sheet, due to its glossy appearance and excellent physical properties, is widely used in cosmetic packaging.

Do you provide product catalogs and quotations?

Yes, we can send you our product catalogs, technical specifications, and competitive quotations upon request. Whether you're interested in standard tinplate sheets, custom aerosol cans, or promotional packaging, Dekai offers fast, accurate pricing to support your purchasing decisions. Contact us to receive the latest catalog and get a discount quote tailored to your project.