The carbon footprint refers to the total amount of carbon dioxide and other greenhouse gas emissions generated during the production, transportation, use, and disposal of a product. It has become a key indicator of the environmental impact of industrial production. What is the carbon footprint of tinplate production, a packaging material widely used in the food, beverage, and chemical industries?

In addition, what common containers can tinplate sheet be made into? This article will explore these issues in depth from multiple perspectives, including production processes, material properties, and product applications.

Tinplate Sheet: Production Process and Carbon Footprint

Tinplate is a corrosion-resistant metal material coated with a thin layer of tin on the surface of steel. Tinplate's primary raw material is low-carbon steel, and its production process involves multiple steps, including steelmaking, hot rolling, cold rolling, tin plating, and finishing. Because each production step consumes energy and is associated with greenhouse gas emissions, understanding the tinplate production process is crucial for assessing its carbon footprint.

1. Carbon Emissions from Steelmaking

Tinplate sheet is based on low-carbon steel, and steel production is one of the primary sources of carbon emissions in the entire process. Steelmaking typically requires high-temperature processing, especially when using coke and coal as reducing agents, which produces large amounts of carbon dioxide and other greenhouse gases. According to the International Energy Agency, the global steel industry accounts for approximately 8% of global industrial carbon emissions, making it the largest contributor to carbon emissions among all industries. Although tinplate sheet production may have slightly lower carbon emissions than conventional steel production, its overall carbon footprint remains relatively large.

2. Energy Consumption in Hot and Cold Rolling

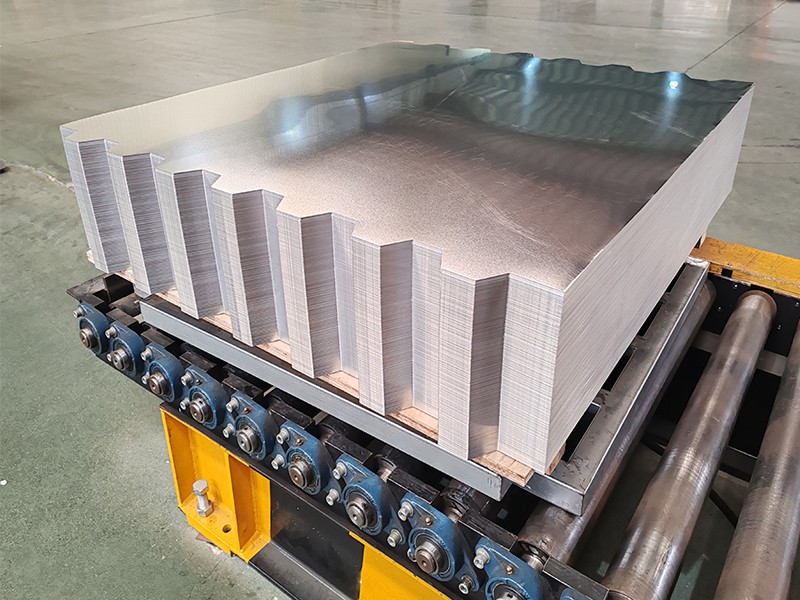

After steelmaking, low-carbon steel billets are fed into rolling mills for hot and cold rolling. Hot rolling heats the billets to extremely high temperatures to soften them and make them suitable for further processing. This process consumes a significant amount of energy, primarily from fuel combustion and electricity usage. Cold rolling, performed at room temperature, consumes relatively little energy, but the entire steel sheet forming process still requires significant electricity. Therefore, these two processes are also significant sources of carbon emissions.

3. Environmental Challenges of Tinplate Coating

The core characteristic of tinplate sheet is its thin layer of tin coating. This tinning process is a critical step in tinplate production. Traditional tinplating uses electroplating, depositing tin ions onto the surface of steel sheets through an electric current. While this process consumes less energy than steelmaking and rolling, it still requires significant amounts of electricity. Especially in large-scale production, this electricity consumption and associated carbon emissions are significant. Furthermore, the industrial wastewater and waste generated during the tinplating process also impact the environment, requiring additional energy to process, which also increases the carbon footprint.

4. Energy Consumption in Processing and Transportation

After tinplating, tinplate sheets undergo a series of finishing steps, including cutting, forming, coating, and printing. These steps require significant electricity to operate the machinery and cooling and drying processes. Furthermore, the transportation of tinplate sheets contributes to carbon emissions. Due to the global nature of tinplate production and consumption, tinplate sheets often need to be transported long distances to their intended locations. The use of fossil fuels, such as diesel and gasoline, during transportation directly contributes to CO2 emissions.

What containers can tinplate sheet be made into?

Tinplate sheet not only offers excellent corrosion resistance but also is strong, durable, and easy to process, making it an ideal material for a variety of containers. The following are several common types of tinplate containers.

1. Food Cans

Food cans are a representative application of tinplate products. Since the advent of canning technology in the 19th century, the importance of tinplate cans in food storage has continued to grow. Tinplate cans offer excellent sealing properties, effectively isolating air and light, preventing food from spoiling. Common tinplate food cans include canned fruit, canned meat, and canned seafood. These cans are not only convenient for storage but also have a long shelf life, making them widely used in the global food supply chain.

2. Beverage Cans

Tinplate beverage cans, especially for carbonated beverages and beer, offer excellent sealing properties. Compared to aluminum cans, tinplate cans are more suitable for carbonated beverages due to their higher surface hardness and better pressure resistance. Tinplate sheet also effectively protects beverages from contact with the outside world, preventing oxidation reactions that may affect the taste of the beverage. Furthermore, tinplate cans can be printed and decorated to enhance the visual appeal of beverage brands.

3. Chemical Product Containers

Tinplate sheet is also widely used to package chemical products, such as paint cans and solvent cans. These products are often highly corrosive or flammable. Tinplate, with its excellent corrosion resistance and mechanical strength, effectively protects the stability of the contents. Furthermore, tinplate's hardness and pressure resistance provide resistance to external physical impact, reducing the risk of damage during transportation.

4. Tea Cans and Biscuit Boxes

Common household packaging containers such as tea cans and biscuit boxes are also typical applications for tinplate. Since tea and biscuits are very sensitive to moisture and light, tinplate sheet effectively protects them, ensuring their quality is not affected. These tinplate containers are not only moisture-proof and light-proof, but also offer attractive designs, making them very popular in the market. In particular, tinplate tea cans and biscuit boxes are often designed with highly decorative features, enhancing the product's premium feel.

5. Pharmaceutical Packaging

In certain special cases, tinplate containers are also used for pharmaceutical packaging. For example, topical medications such as ointments and creams often require a long shelf life. Tinplate packaging effectively isolates them from external contaminants and prevents them from spoiling. Furthermore, tinplate containers protect medications from moisture and heat, ensuring their long-lasting effectiveness.

6. Spray Cans

Tinplate sheet is also used in the production of spray cans, particularly for cosmetics and daily chemical products. Spray cans must withstand high-pressure gases, and the packaging material must be chemically inert to the contents, making tinplate sheet an ideal choice for these containers. Tinplate spray cans are commonly used to hold products such as hairspray, deodorant, and detergents. They maintain stable pressure for extended periods and prevent contamination or leakage.

What are the advantages of tinplate packaging containers?

As a packaging material, tinplate sheet offers many advantages in both production and use. The following are some key advantages of tinplate containers:

1. Excellent Corrosion Resistance

Tinplate is widely used in food and beverage packaging primarily due to its excellent corrosion resistance. The tin layer effectively blocks contact with air and moisture, preventing oxidation and rust. It also protects the contents of the container from environmental influences, extending the shelf life of food and beverages.

2. High Mechanical Strength

Tinplate sheet possesses superior mechanical strength compared to other materials such as aluminum and plastic. It resists external impact and compression during transportation and storage, reducing the risk of product damage. Tinplate containers can withstand significant internal and external pressure, making them particularly suitable for packaging carbonated beverages and gaseous products.

3. High Plasticity

Tinplate sheet's plasticity makes it suitable for a wide variety of container designs. Through processes such as stamping, bending, and stretching, tinplate can be formed into a variety of complex container shapes to meet the packaging needs of diverse products. Furthermore, tinplate sheet's smooth surface allows for decoration through coatings and printing, enhancing the product's aesthetics and market appeal.

Why should companies buy aerosol cans from Dekai?

Dekai is a leading aerosol can manufacturer in China, with annual production capacity exceeding 300 million cans. Our factory-direct supply ensures cheap prices and high-quality standards. We use advanced production lines and strict ISO9001 quality management, giving customers confidence in safety and durability.

Companies looking for bulk sales, wholesale purchasing, or promotional discounts will find Dekai the right partner. We provide quick quotes, customized branding options, and reliable delivery.