In the field of food packaging, biscuits, as a popular snack, have always required carefully designed packaging to maintain freshness, enhance brand image and attract consumers' attention. As a common packaging material, tinplate sheet has become an ideal choice for making cookie packaging tin due to its excellent mechanical properties, corrosion resistance and plasticity.

So, why choose tinplate sheet for cookie packaging tin? What are the principles and precautions when using tinplate sheet to make cookie packaging tin? These issues are crucial in the packaging industry and are related to the preservation, brand image and market performance of biscuits.

This article will explore the application of tinplate sheet in cookie packaging tin, analyze the reasons for choosing tinplate sheet, and answer in detail the basic principles that should be followed when making cookie packaging tin.

Why choose tinplate sheet to make cookie packaging tin?

What are the unique advantages of tinplate sheet?

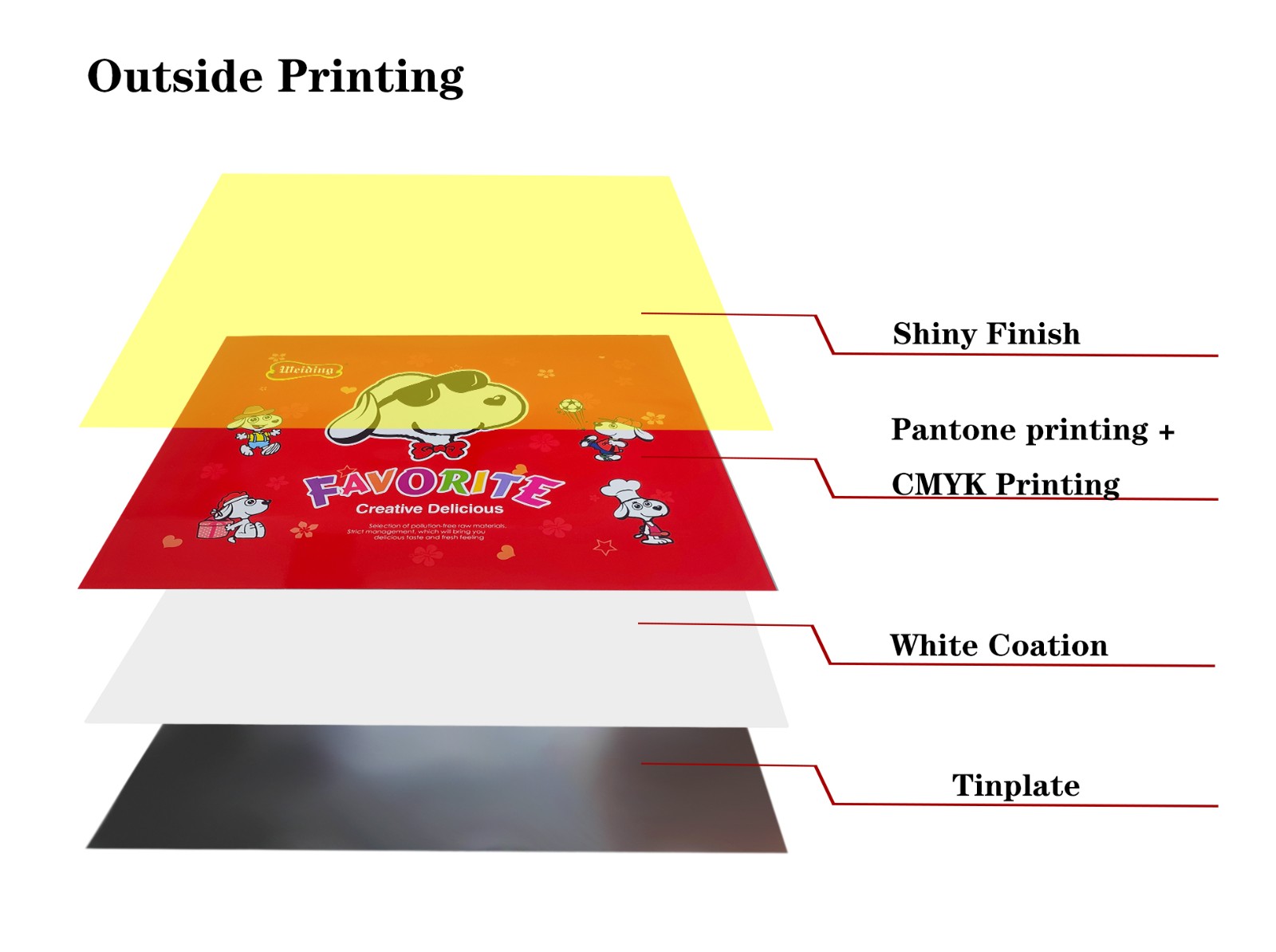

After special processing, tinplate sheet is coated with a thin layer of tin on the surface, which has strong corrosion resistance and plasticity, making it an ideal food packaging material. Especially in biscuit packaging, the advantages of using tinplate sheet are particularly prominent.

● Strong protection: tinplate sheet has good moisture-proof, anti-oxidation and anti-corrosion properties, which is essential for foods such as biscuits that are easily affected by moisture, fragile and sensitive to air, moisture and oxygen. Packaging tins can effectively prevent the external environment from affecting the quality of biscuits and extend the shelf life.

● Strong structure: The firmness of tinplate sheet can protect the integrity of biscuits during transportation, handling and storage, and prevent the packaging from being damaged and causing the biscuits to break or deteriorate. Tinplate packaging tins can prevent crushing and extrusion, effectively avoiding food waste caused by packaging damage.

● Recyclability: As a metal material, tinplate sheet has high recyclability. Enterprises use tinplate packaging tins, which is not only in line with environmental protection trends, but also reduces resource waste. After using the packaging, consumers can also recycle the tinplate sheet cans to further promote the concept of environmental protection.

● Good printing effect: The surface of tinplate sheet is smooth and suitable for high-quality printing. This feature enables brand owners to print exquisite patterns, trademarks, texts, etc. on packaging tins to enhance brand image and enhance consumers' desire to buy.

What are some other materials suitable for cookie packaging?

In addition to tinplate sheets, there are many other packaging materials on the market, such as plastic, glass, cardboard, etc. So why is tinplate sheet more common in cookie packaging tin among so many choices?

● Plastic packaging: Although plastic packaging is widely used in the food industry and has low production costs, it is generally less resistant to moisture and high temperatures. For foods that are easily affected by moisture, such as biscuits, plastic packaging often does not provide the same protection as tinplate sheet packaging.

● Glass bottle packaging: Glass bottle packaging is generally considered to be more upscale, but it is heavy, fragile, and has a higher transportation cost. In contrast, tinplate packaging tins are lighter, more durable, and less likely to break during transportation.

● Cardboard packaging: Cardboard packaging is inexpensive, but has poor moisture resistance and cannot match tinplate sheet in terms of protection. The high strength and corrosion resistance of tinplate sheet make it more advantageous in terms of protection.

Therefore, tinplate sheet has been widely used in biscuit packaging due to its superior performance, especially moisture-proof, strong protection and good appearance printing effect.

Basic principles for making cookie packaging tins with tinplate sheet

How to ensure the appropriate size of cookie packaging tins?

When making cookie packaging tins, the size of packaging tins must be determined first. The choice of size not only directly affects the cost of packaging, but also the performance of the product in the market. The size should be determined based on the following factors:

● Volume and shape of biscuits: Different forms of biscuits require cookie packaging tins of different shapes. Common biscuits are round, square, thin, etc. The design of packaging tins should determine the size based on these characteristics.

● Packaging method: Biscuit packaging is usually filled manually or automatically. When filling automatically, the size of cookie packaging tins needs to match the standard caliber of the filling equipment to ensure the efficiency of production.

● Market positioning and capacity requirements: The capacity of cookie packaging tins should be adjusted according to market positioning and consumer demand. For example, small portable packaging is suitable for daily household consumption, while large-capacity packaging is suitable for bulk sales in supermarkets and shopping malls.

How to ensure the sealing of cookie packaging tins?

The sealing of cookie packaging tins is the key to ensuring the quality of biscuits. Poor sealing may allow external moisture and air to enter, thus affecting the taste and shelf life of biscuits. In order to ensure the sealing of tinplate packaging tins, the following principles must be followed during the manufacturing process:

● Welding technology: The welding part of tinplate packaging tins is the key to sealing. During the production process, it is necessary to ensure the quality of welding and avoid air leakage in the weld.

● Lid design: The design of the can lid is also an important part of ensuring sealing. The use of suitable lid materials and precise lid closing process can effectively ensure the sealing of cookie packaging tins and prevent moisture and air from entering.

● Coating protection: In order to enhance the sealing, the inner wall of tinplate packaging tins is usually coated with a moisture-proof coating to further enhance its moisture-proof function.

How to balance the design and aesthetics of the packaging?

Appearance design plays a vital role in biscuit packaging. It not only affects consumers' purchasing decisions, but also conveys the brand's philosophy and culture. When choosing tinplate sheet as a packaging material, designers and brand owners need to find a balance between functionality and aesthetics.

● Selection of printing technology: The surface of tinplate sheet is smooth and can withstand high-quality printing, so packaging designers can choose a variety of printing processes, such as screen printing, offset printing, etc., to achieve the best visual effect. Through exquisite design and pattern, packaging tins can attract consumers' attention and enhance brand recognition.

● Equal emphasis on functionality and aesthetics: While pursuing the appearance of packaging, the functionality of packaging cannot be ignored. Tinplate packaging tins must be able to effectively protect the quality of biscuits and consider the visual effect of packaging to maximize consumers' desire to buy.

● Choice of color and pattern: The combination of color and pattern has a greater psychological impact on consumers. When designing tinplate sheet packaging, companies should consider the target group and market positioning of the product. For example, the packaging design of children's snacks should use bright and lively colors, while high-end biscuits should adopt a simple and elegant design style.

How to ensure quality control during production?

In the production process of tinplate packaging tins, quality control is a key link to ensure that the final product meets the standards. Enterprises need to strictly control the following aspects:

● Material selection: The quality of tinplate sheet directly affects the durability and protection of packaging tins. Therefore, choosing high-quality tinplate sheet materials is the prerequisite for ensuring packaging quality.

● Production process: In the manufacturing process of packaging tins, welding, stamping, molding and other processes require fine operation. Every link in the production process must be strictly controlled to ensure that the size, sealing and appearance of packaging tins meet the predetermined standards.

● Quality inspection: After production, packaging tins need to undergo strict quality inspection, including sealing test, size test, coating test, etc. Through multiple rounds of inspection, ensure that each batch of products meets high standards.

For affordable and high-quality metal packaging, choose Foshan Dekai Metal Packaging Co., Ltd., a professional manufacturer and supplier in Guangdong, China. Our 50,000-square-meter facility is equipped with FUJI printing lines and high-speed production equipment. We specialize in tinplate printing, aerosol cans, and customized designs, offering wholesale options and low-cost solutions for bulk buyers. ISO9001-certified and known for innovation, we deliver reliable products tailored to your needs. Contact us for quotes and promotions.